This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3402170 Ring Dowel is a specialized component designed for use in heavy-duty truck engines. Its purpose is to ensure precise alignment and secure fitting of various engine components, contributing to the overall efficiency and reliability of the engine system. Understanding the role and significance of this Cummins part is important for maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Ring Dowels

A ring dowel is a cylindrical component used in mechanical assemblies to align and secure parts in place. In engine or transmission systems, ring dowels play a role in maintaining the correct positioning of components, which is vital for the smooth operation and longevity of the system. They are typically made from durable materials to withstand the stresses and vibrations encountered in heavy-duty applications 1.

Purpose of the 3402170 Ring Dowel

The Cummins 3402170 Ring Dowel is specifically designed to align and secure components within the engine. It ensures that parts are correctly positioned relative to each other, which is important for the efficient operation of the engine. By maintaining proper alignment, the ring dowel helps to reduce wear and tear on moving parts, contributing to the overall durability and performance of the engine 2.

Key Features

The 3402170 Ring Dowel is characterized by several key features that enhance its performance. It is constructed from high-quality materials to ensure durability and resistance to wear. The design specifications of the ring dowel are tailored to fit precisely within the engine assembly, providing a secure and stable connection between components. Additionally, the ring dowel may have unique attributes such as a specific diameter or length that are optimized for its intended application 3.

Benefits of Using the 3402170 Ring Dowel

Utilizing the 3402170 Ring Dowel offers several advantages. It improves the alignment of engine components, which can lead to enhanced performance and efficiency. The durable construction of the ring dowel contributes to its longevity, reducing the need for frequent replacements. Furthermore, by ensuring proper component fitting, the ring dowel plays a role in maintaining the overall efficiency of the engine or transmission system 4.

Installation Process

Proper installation of the 3402170 Ring Dowel is important for ensuring its effectiveness. The installation process involves carefully positioning the ring dowel within the engine assembly and securing it in place. Best practices include verifying that the ring dowel is correctly aligned with other components and ensuring that it is firmly seated to prevent movement. It is also important to avoid common pitfalls such as over-tightening, which can damage the ring dowel or surrounding parts 5.

Troubleshooting and Maintenance

Common issues associated with ring dowels include misalignment and wear. Troubleshooting may involve checking the alignment of the ring dowel and ensuring that it is securely fitted. Regular maintenance practices, such as inspecting the ring dowel for signs of wear or damage, can help to ensure its longevity and optimal performance. Additionally, following manufacturer guidelines for maintenance can contribute to the overall reliability of the engine system 6.

Compatibility and Usage

The 3402170 Ring Dowel is designed for use in specific types of trucks and engines. It is important to verify compatibility with the intended application to ensure proper fit and function. Understanding the specific models or series for which the ring dowel is intended can help in selecting the appropriate component for maintenance or replacement 7.

Historical Context and Evolution

The development of ring dowels, including the introduction of the 3402170 by Cummins, reflects the industry’s ongoing efforts to improve the reliability and performance of heavy-duty truck engines. Over time, ring dowels have evolved to meet the changing needs of the industry, with advancements in materials and design contributing to their effectiveness in modern engine systems 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products and commitment to quality. The company’s history is marked by innovation and a focus on meeting the needs of its customers. Cummins’ product range includes engines, filtration systems, and other components designed to enhance the performance and reliability of heavy-duty vehicles. The reputation of Cummins in the industry is built on its expertise, quality products, and customer-centric approach 9.

Ring Dowel Part 3402170 Compatibility with Cummins Engines

The Ring Dowel part 3402170, manufactured by Cummins, is a critical component in the assembly of several of their engine models. This part is designed to ensure proper alignment and stability of the piston rings within the engine cylinder, which is essential for maintaining optimal engine performance and longevity.

ISX15 CM2250

The ISX15 CM2250 engine benefits from the precision and reliability of the Ring Dowel part 3402170. This part ensures that the piston rings maintain their correct position, contributing to the engine’s overall efficiency and durability.

QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM2350 K144G

The QSK19 CM2350 series, including the K105, K114, and K144G variants, all utilize the Ring Dowel part 3402170. This component is integral to the engine’s operation, providing the necessary support for the piston rings to function correctly. The consistent use of this part across these models underscores its importance in maintaining engine integrity.

QSK19 CM500, QSK19 CM850 MCRS

The QSK19 CM500 and QSK19 CM850 MCRS engines also incorporate the Ring Dowel part 3402170. This part’s role in these engines is to ensure that the piston rings are properly aligned, which is crucial for the engines’ performance and reliability.

QSK19G

The QSK19G engine is another model that relies on the Ring Dowel part 3402170. This part’s precision engineering is essential for the engine’s operation, ensuring that the piston rings are correctly positioned to maintain engine efficiency and longevity.

By using the Ring Dowel part 3402170 across these various engine models, Cummins ensures that each engine benefits from a component designed to provide stability and precision, contributing to the overall performance and reliability of the engine 10.

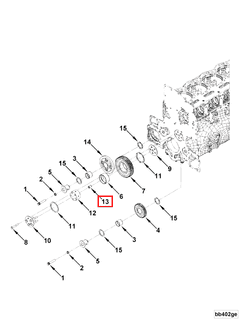

Role of Part 3402170 Ring Dowel in Engine Systems

The Part 3402170 Ring Dowel is instrumental in ensuring the precise alignment and secure fitting of various components within engine systems. Its application spans across multiple assemblies, contributing to the overall integrity and functionality of the engine.

Cylinder Block

In the Cylinder Block, the Ring Dowel aids in the accurate positioning of the block relative to other engine components. This ensures that the cylinder bores are correctly aligned with the crankshaft and other moving parts, which is essential for smooth engine operation and longevity.

Idler Shaft

For the Idler Shaft, the Ring Dowel plays a role in maintaining the shaft’s alignment within the engine. Proper alignment is necessary to prevent undue stress on the shaft and to ensure efficient power transmission through the engine’s timing system.

PDC (Powertrain Control Module)

When integrated with the PDC, the Ring Dowel helps in securing sensor adapters and other critical components that interface with the module. This ensures that the sensors provide accurate readings, which are vital for the PDC to manage engine performance effectively.

Sensor Adapter

In conjunction with Sensor Adapters, the Ring Dowel ensures that these adapters are correctly positioned. This is important for the sensors to function accurately, providing the engine control unit with reliable data for optimal engine management.

Service Coupling Assemblies

For the Service Coupling 2008 Assembly and Service Coupling 2009 Assembly, the Ring Dowel is used to maintain the precise alignment of these couplings. This is essential for the efficient transfer of power and the smooth operation of the engine’s ancillary systems.

Short Block Kit

In a Short Block Kit, the Ring Dowel is utilized to ensure that all components within the kit are correctly aligned and fitted. This is particularly important for the crankshaft, pistons, and cylinder block, ensuring that the engine can operate smoothly and efficiently once assembled.

Conclusion

The Cummins 3402170 Ring Dowel plays a significant role in the alignment and secure fitting of engine components, contributing to the overall efficiency and reliability of heavy-duty truck engines. Its durable construction and precise design ensure that engine components are correctly positioned, reducing wear and tear and enhancing performance. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are key to maximizing the benefits of this Cummins part.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Cummins Inc. (n.d.). QSK19 CM2350 K105, Service Manual (4326157).

↩ -

Cummins Inc. (n.d.). QSK19 CM2350 K105, Service Manual (4326157).

↩ -

Cummins Inc. (n.d.). QSK19 CM2350 K105, Service Manual (4326157).

↩ -

Cummins Inc. (n.d.). QSK19 CM2350 K105, Service Manual (4326157).

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). QSK19 CM2350 K105, Service Manual (4326157).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.