This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

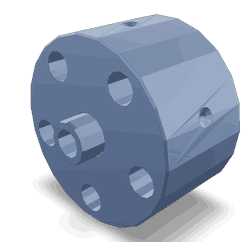

The Cummins 3402171 Idler Shaft is a component designed for use in heavy-duty trucks, contributing to the efficient operation of the transmission system. Cummins Inc., a well-regarded manufacturer in the automotive industry, produces this part. This overview will explore the purpose and function of the 3402171 Idler Shaft within the context of heavy-duty truck transmissions.

Basic Concepts of Idler Shafts

An idler shaft is a component found in transmission systems that facilitates the transfer of power between gears. It operates by maintaining proper alignment and spacing between gears, allowing for smooth and efficient power transmission. In mechanical systems, idler shafts are essential for ensuring that gears mesh correctly, which is vital for the overall performance and longevity of the transmission 1.

Purpose of the 3402171 Idler Shaft

The 3402171 Idler Shaft is specifically designed to enhance the transmission system’s efficiency in heavy-duty trucks. It plays a role in maintaining the correct alignment of gears, which is necessary for the seamless transfer of power. By ensuring that gears are properly aligned, the idler shaft contributes to the reduction of wear on other transmission components and helps in achieving optimal gear engagement 2.

Key Features

The 3402171 Idler Shaft is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to wear and capable of withstanding the high stresses encountered in heavy-duty applications. The design of the shaft includes precision-machined surfaces to ensure smooth operation and reliable gear engagement. Additionally, the idler shaft may feature unique characteristics such as specialized coatings or treatments that further improve its durability and performance under demanding conditions 3.

Benefits of Using the 3402171 Idler Shaft

Incorporating the 3402171 Idler Shaft into a truck’s transmission system offers several advantages. It contributes to improved gear engagement, which is essential for efficient power transmission. The use of this idler shaft can also lead to reduced wear on other transmission components, extending their service life. Furthermore, the 3402171 Idler Shaft enhances the overall efficiency of the transmission system, potentially leading to better fuel economy and performance 4.

Installation Considerations

When installing the 3402171 Idler Shaft, it is important to follow guidelines and best practices to ensure optimal performance and longevity. Proper alignment of the shaft within the transmission is crucial, as is adhering to the manufacturer’s torque specifications during installation. Careful attention to these details helps prevent issues such as misalignment or excessive wear, ensuring the idler shaft functions as intended.

Troubleshooting Common Issues

Common problems associated with idler shafts, such as noise, vibration, or gear slippage, can often be traced back to installation errors or wear and tear. Troubleshooting these issues involves a systematic approach to identify the root cause. This may include checking the alignment of the shaft, inspecting for wear on the shaft or gears, and ensuring that all components are properly lubricated. Addressing these issues promptly can help maintain the efficiency and reliability of the transmission system.

Maintenance Tips

Regular maintenance practices are key to prolonging the life of the 3402171 Idler Shaft. This includes routine lubrication to reduce friction and wear, as well as periodic inspection for signs of wear or damage. Timely replacement of worn components is also important to prevent further damage to the transmission system. Following these maintenance tips can help ensure the idler shaft continues to operate efficiently and reliably.

Cummins as a Manufacturer

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry. The company is known for its commitment to quality and innovation in the production of automotive components. Cummins’ history of excellence and dedication to advancing technology in the field of automotive manufacturing underscores the reliability and performance of its products, including the 3402171 Idler Shaft.

Compatibility with Cummins Engines

The Idler Shaft part number 3402171, manufactured by Cummins, is designed to fit into a variety of Cummins engines. This part plays a role in the engine’s operation by maintaining proper tension and alignment of the timing belt or chain, ensuring smooth and efficient engine performance.

QSK19 Series

The Idler Shaft 3402171 is compatible with several models within the QSK19 series:

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

These engines are part of the QSK19 series, which are known for their robust design and reliability in various industrial applications. The 3402171 Idler Shaft ensures that the timing components operate correctly, reducing wear and extending the engine’s lifespan.

Other Cummins Engines

In addition to the QSK19 series, the Idler Shaft 3402171 is also suitable for:

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

These engines, while part of different series, share common design principles that allow the 3402171 Idler Shaft to fit seamlessly. The compatibility ensures that the timing system functions optimally, contributing to the overall performance and durability of the engine.

Role of Part 3402171 Idler Shaft in Engine Systems

The 3402171 Idler Shaft is an integral component within various engine systems, facilitating the smooth operation of multiple assemblies and ensuring the efficient transfer of mechanical energy.

In the Cylinder Block and Block assemblies, the Idler Shaft plays a significant role in maintaining the timing and synchronization of the engine’s moving parts. It ensures that the camshaft and crankshaft operate in harmony, which is essential for the engine’s performance and longevity.

When incorporated into a Short Block Kit, the Idler Shaft contributes to the kit’s overall functionality by supporting the valve train components. This support is vital for the precise opening and closing of the engine’s valves, directly influencing combustion efficiency and power output.

In the PDC (Power Distribution Center) system, the Idler Shaft assists in distributing power evenly across the engine’s components. This balanced distribution is key to preventing undue stress on any single part, thereby enhancing the engine’s reliability and durability.

The Idler Shaft is also a component in the Service Coupling 2008 Assembly and Service Coupling 2009 Assembly. In these assemblies, it helps in the smooth transmission of rotational force from the engine to the ancillary components, such as the alternator or air conditioning compressor. This ensures that these components receive consistent and adequate power, which is necessary for their efficient operation.

Lastly, in the Kit assemblies, the Idler Shaft is often included to provide a comprehensive solution for engine maintenance or upgrade. Its presence in these kits ensures that all necessary components for a smooth and efficient engine operation are available, making the kit a valuable resource for both maintenance and performance enhancement projects.

Conclusion

The Cummins 3402171 Idler Shaft is a critical component in the efficient operation of heavy-duty truck transmissions and Cummins engines. Its role in maintaining gear alignment, enhancing transmission efficiency, and ensuring the smooth operation of engine systems underscores its importance in automotive applications. Proper installation, maintenance, and understanding of its function are essential for maximizing the performance and longevity of this Cummins part.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Robert Huzij, Angelo Spano, and Sean Bennett, Modern Diesel Technology: Heavy Equipment Systems (Cengage Learning, 2019).

↩ -

John Heywood, Internal Combustion Engine Fundamentals (McGraw-Hill Education, 2019).

↩ -

Robert Bosch GmbH, Bosch Automotive Handbook 9th Edition (Robert Bosch GmbH, 2014).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.