This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

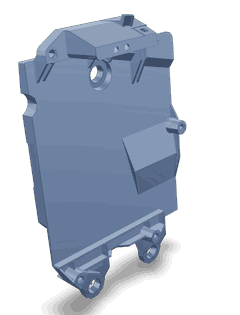

The Electronic Control Module Bracket, Part #4993966 by Cummins, is a component designed to support and secure the Electronic Control Module (ECM) in truck operations. Cummins Inc., a well-established manufacturer in the commercial truck industry, produces this bracket. The ECM bracket is integral to maintaining the ECM’s position and protecting it from environmental factors and physical damage.

Function and Purpose

The Electronic Control Module Bracket plays a role in the operation of a truck by providing a secure mounting point for the ECM. This bracket ensures that the ECM remains in place and is protected from vibrations, impacts, and other potential damages that could occur during truck operation. The ECM, which is responsible for managing various engine functions and diagnostics, relies on the bracket to maintain its operational integrity. The bracket also facilitates the connection of the ECM to other components through wiring harnesses, ensuring reliable communication and data transfer within the truck’s electronic system 1.

Key Features

The design and construction of the Electronic Control Module Bracket include several features that enhance its performance and durability. Constructed from high-strength materials, the bracket is resistant to corrosion and capable of withstanding the harsh conditions often encountered in truck environments. It features multiple mounting points that allow for secure attachment to the truck’s chassis, ensuring stability. The bracket’s design also incorporates provisions for efficient heat dissipation, which helps in maintaining the optimal operating temperature of the ECM 2.

Benefits

The Electronic Control Module Bracket offers several advantages that contribute to the overall reliability and performance of a truck. By providing a stable and secure mounting solution for the ECM, it helps in protecting the sensitive electronic components from physical damage and environmental factors. This protection enhances the ECM’s longevity and ensures consistent performance. Additionally, the bracket’s design contributes to the overall stability of the truck’s electronic system, facilitating reliable communication between the ECM and other components 3.

Installation and Compatibility

Proper installation of the Electronic Control Module Bracket is crucial for ensuring its effectiveness. The installation process involves securing the bracket to the truck’s chassis using the provided mounting hardware. It is important to follow the manufacturer’s guidelines to ensure a secure fit. Tools required for installation may include a torque wrench for tightening bolts to the specified torque settings. Compatibility information for this bracket, including specific truck models and engine types, should be consulted to ensure proper fitment and function 4.

Maintenance and Troubleshooting

Regular maintenance of the Electronic Control Module Bracket is important for ensuring its longevity and optimal performance. This includes checking the bracket for signs of corrosion, damage, or loose mounting points. Cleaning the bracket and ensuring that all connections are secure can help prevent issues related to ECM performance. Common issues that may arise include corrosion at mounting points or damage to the bracket itself. Troubleshooting steps may involve inspecting the bracket for physical damage, ensuring all connections are secure, and addressing any corrosion with appropriate treatments 5.

Safety Considerations

When working with the Electronic Control Module Bracket, it is important to observe several safety guidelines and precautions. Electrical safety is paramount, as the bracket is in close proximity to the ECM and its wiring. Ensure that the truck’s battery is disconnected before beginning any work to prevent the risk of electrical shock. Additionally, proper handling procedures should be followed to avoid damage to the bracket or the ECM during installation or maintenance. Wearing appropriate personal protective equipment (PPE) is also recommended 6.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its product range, which is designed to meet the demanding requirements of truck operators worldwide. Cummins’ focus on quality and innovation ensures that its components, including the Electronic Control Module Bracket, contribute to the efficient and reliable operation of trucks 7.

Compatibility of Electronic Control Module Bracket Part 4993966 with Cummins Engines

The Electronic Control Module (ECM) Bracket part 4993966, manufactured by Cummins, is designed to fit a range of Cummins engines, ensuring secure mounting and alignment of the ECM. This bracket is integral for maintaining the operational integrity of the engine’s electronic control system. Below is a detailed compatibility overview of this bracket with various Cummins engines:

ISB Series Engines

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

The ISB series engines, including the ISB CM2150, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, and ISB6.7 CM2250, are compatible with the ECM Bracket part 4993966. This bracket ensures that the ECM is properly positioned and secured, facilitating effective communication between the engine’s control system and other electronic components.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines, specifically the ISBE CM2150 and ISBE4 CM850, also utilize the ECM Bracket part 4993966. This compatibility is crucial for maintaining the alignment and stability of the ECM, which is essential for the proper functioning of the engine’s electronic control unit.

ISD Series Engines

- ISD4.5 CM2220 D108

The ISD4.5 CM2220 D108 engine is another model that is compatible with the ECM Bracket part 4993966. This bracket ensures that the ECM is securely mounted, which is vital for the engine’s electronic systems to operate correctly.

QSB Series Engines

- QSB4.5 CM850(CM2850)

- QSB6.7 CM850(CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines, including the QSB4.5 CM850(CM2850), QSB6.7 CM850(CM2850), QSB6.7 M CM2250, and QSB7 CM2880 B117, are also compatible with the ECM Bracket part 4993966. This compatibility ensures that the ECM is properly positioned and secured, which is essential for the engine’s electronic control systems to function effectively.

Role of Part 4993966 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 4993966, serves as a foundational component in the integration of the ECM within various engine systems. This bracket is engineered to securely mount the ECM, ensuring it remains stable and protected during engine operation.

In the context of engine control modules, the ECM bracket facilitates the connection between the ECM and other vital components such as sensors, actuators, and the engine control unit (ECU). By providing a stable mounting point, the bracket allows for efficient signal transmission and data exchange, which are essential for the ECM to monitor and adjust engine performance in real-time.

Additionally, the ECM bracket plays a role in thermal management. It helps dissipate heat generated by the ECM, preventing overheating and ensuring optimal operation. This is particularly important in high-performance engines where the ECM is subjected to significant thermal loads.

The bracket also aids in the organization of wiring harnesses connected to the ECM. By keeping wires neatly arranged and secured, it reduces the risk of electrical interference and ensures reliable communication between the ECM and other engine components.

In summary, the ECM bracket is an integral component that supports the functional and structural integrity of the ECM within engine systems, contributing to efficient engine management and performance 8.

Conclusion

The Electronic Control Module Bracket, Part #4993966 by Cummins, is a critical component in the operation and maintenance of truck engines. Its role in securing the ECM, facilitating communication between engine components, and managing thermal loads ensures the efficient and reliable performance of the engine. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are essential for maximizing the benefits of this part.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4326162.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4326162.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.