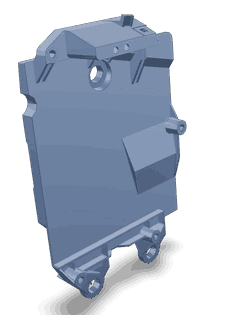

5309216

Electronic Control Module Bracket

Cummins®

BACK ORDERED

Please contact us for information on lead time

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5309216 Electronic Control Module (ECM) Bracket, manufactured by Cummins, is a component designed to support the operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is integral to the electronic systems of these trucks, ensuring the proper function and security of the ECM.

Basic Concepts of Electronic Control Module Brackets

An Electronic Control Module (ECM) Bracket serves as a mounting solution for the ECM, which is the brain of a truck’s electronic system. The ECM manages various engine functions, including fuel injection, emissions control, and engine timing. The bracket’s role is to securely hold the ECM in place, protecting it from physical damage and environmental factors. It also facilitates the connection between the ECM and other electronic components through wiring harnesses 1.

Purpose of the 5309216 Electronic Control Module Bracket

This part is designed to play a role in the operation of a truck by securing the ECM and facilitating its operation. By providing a stable mounting point, it ensures that the ECM remains in the correct position and orientation, which is vital for the accurate reading of sensor data and the execution of control commands. This bracket contributes to the overall reliability of the truck’s electronic system by protecting the ECM from vibrations, impacts, and exposure to the elements.

Key Features

The 5309216 ECM Bracket is constructed from durable materials that offer resistance to corrosion and physical stress. Its design includes features such as mounting points that align precisely with the ECM’s attachment points and provisions for securing wiring harnesses. These design elements contribute to the bracket’s functionality by ensuring a secure fit and easy integration with the truck’s electronic system.

Benefits

The 5309216 ECM Bracket provides several benefits, including improved ECM security through its robust construction and secure mounting. This enhances the durability of the ECM and can lead to potential improvements in truck performance and reliability. By maintaining the integrity of the ECM’s position and connections, the bracket helps ensure that the truck’s electronic systems operate efficiently.

Installation Process

Installing the 5309216 ECM Bracket involves several steps. Preparatory steps include ensuring the truck’s engine compartment is clean and free of debris that could interfere with the installation. The necessary tools may include wrenches, screwdrivers, and possibly a torque wrench to secure the bracket in place. Best practices for installation include following the manufacturer’s instructions closely, ensuring all connections are secure, and verifying that the ECM is properly aligned and seated in the bracket.

Troubleshooting and Maintenance

Common issues with the 5309216 ECM Bracket may include loose connections or physical damage to the bracket itself. Regular maintenance involves inspecting the bracket and its connections for signs of wear or corrosion. If the bracket shows signs of damage or if the ECM’s performance seems compromised, it may be an indication that the bracket needs to be repaired or replaced.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Electronic Control Module Bracket 5309216 Compatibility

The Cummins Electronic Control Module (ECM) Bracket part number 5309216 is designed to be compatible with a range of Cummins engines, ensuring a secure mounting for the ECM. This bracket is essential for maintaining the integrity of the engine’s electronic control system.

ISB and ISBE Series Engines

The ISB and ISBE series engines, including the ISB CM2150, ISB/ISD4.5 CM2150 B119, ISB/ISD6.7 CM2150 SN, ISB6.7 CM2250, ISBE CM2150, and ISBE4 CM850, all feature a standardized mounting point for the ECM. The 5309216 bracket fits these engines seamlessly, providing a robust and reliable connection that ensures the ECM remains securely in place.

ISD Series Engines

The ISB/ISD4.5 CM2220 D108 engine also benefits from the 5309216 bracket. This bracket is engineered to fit the specific mounting requirements of the ISD series, ensuring that the ECM is properly aligned and secured.

QSB Series Engines

The QSB series engines, including the QSB4.5 CM850 (CM2850), QSB6.7 CM850 (CM2850), QSB6.7 M CM2250, and QSB7 CM2880 B117, are designed to work with the 5309216 bracket. This bracket is compatible with the QSB engines’ mounting specifications, providing a reliable solution for ECM mounting.

By using the Cummins ECM Bracket part number 5309216, technicians and operators can ensure that the ECM is securely mounted across a variety of Cummins engine models, facilitating optimal performance and reliability.

Role of Part 5309216 Electronic Control Module Bracket in Engine Systems

The Electronic Control Module (ECM) Bracket, identified by part number 5309216, serves as a foundational component in the integration of the ECM within various engine systems. This bracket is engineered to securely mount the ECM, ensuring it remains stable and protected during engine operation.

Integration with the Engine Control Module

The ECM is the brain of the engine system, responsible for processing data from various sensors and making real-time adjustments to engine performance. The 5309216 bracket provides a robust mounting solution that keeps the ECM in optimal position, allowing for efficient heat dissipation and protection from vibrations. This stability is essential for the ECM to function accurately and reliably, directly influencing the engine’s performance and efficiency.

Interaction with Engine Components

-

Sensors and Actuators: The ECM communicates with a network of sensors and actuators throughout the engine system. The secure mounting provided by the 5309216 bracket ensures that the ECM can effectively receive data from sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and various temperature sensors. It also ensures reliable transmission of commands to actuators like fuel injectors and the throttle body, enhancing overall engine control.

-

Wiring Harnesses: The bracket facilitates the organization and protection of wiring harnesses connected to the ECM. By keeping the ECM in a fixed position, the bracket reduces the risk of wire fatigue or damage, which can lead to intermittent connections or complete failures in the engine control system.

-

Cooling Systems: Effective thermal management is vital for the ECM’s longevity and performance. The 5309216 bracket is designed to allow for adequate airflow around the ECM, often in conjunction with the engine’s cooling system. This helps in maintaining the ECM within its operational temperature range, preventing overheating which could degrade its functionality.

-

Module Housing: In some engine designs, the ECM is housed within a module that includes additional components such as relays or fuses. The bracket ensures that this module is securely attached, preventing any movement that could disrupt the internal connections or cause damage to the components within the housing.

Conclusion

In summary, the 5309216 Electronic Control Module Bracket plays a significant role in the reliable operation of the ECM within engine systems. Its design and placement are tailored to support the ECM’s function, ensuring that it can effectively manage and optimize engine performance through precise control of various engine parameters.

-

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.