4936170

Electronic Control Module Bracket

Cummins®

BACK ORDERED

Please contact us for information on lead time

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

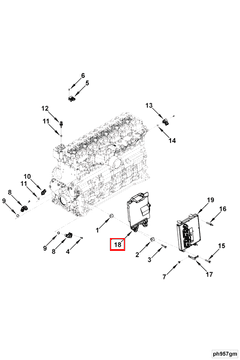

The 4936170 Electronic Control Module (ECM) Bracket is a component designed by Cummins, a leading manufacturer in the commercial truck industry. This bracket serves a significant role in the operation of commercial trucks by providing a secure mounting solution for the ECM. Cummins is renowned for its commitment to quality and innovation, ensuring that its products contribute to the reliability and performance of commercial vehicles 1.

Basic Concepts of Electronic Control Module Brackets

An Electronic Control Module (ECM) Bracket is a structural component that supports and secures the ECM within a truck’s electronic system. The ECM is a critical part of the truck’s engine management system, responsible for controlling various engine functions and ensuring optimal performance. The ECM Bracket interfaces with other components by providing a stable platform for the ECM, protecting it from vibrations, impacts, and environmental factors that could affect its operation 2.

Purpose and Role in Truck Operation

The 4936170 ECM Bracket plays a specific role in the operation of a truck by securely mounting the ECM. This ensures that the ECM remains stable and protected, allowing it to function effectively. The bracket contributes to the ECM’s functionality by providing a solid foundation that minimizes the risk of damage from road vibrations and other external forces. This, in turn, supports the overall performance and reliability of the truck 3.

Key Features

The 4936170 ECM Bracket is designed with several key features that enhance its performance and durability. These include a robust construction that provides excellent protection for the ECM, compatibility with a range of truck models, and a design that ensures easy installation. The materials used in the bracket are selected for their strength and resistance to corrosion, ensuring long-lasting performance in various operating conditions 4.

Benefits

The 4936170 ECM Bracket offers several benefits that contribute to the overall efficiency and reliability of a truck. By providing improved protection for the ECM, the bracket helps to ensure that the ECM operates within optimal conditions, reducing the risk of malfunctions. Additionally, the enhanced stability offered by the bracket can contribute to better fuel efficiency and emissions reduction, as a stable ECM can more accurately control engine functions 5.

Installation Considerations

Proper installation of the 4936170 ECM Bracket is important to ensure its effectiveness. It is designed to be compatible with various truck models, but it is important to verify compatibility before installation. Correct placement and securing of the bracket are crucial to ensure that the ECM is adequately protected and that the bracket performs its intended function. Following the manufacturer’s guidelines for installation will help to ensure optimal performance and longevity of the bracket 6.

Troubleshooting and Maintenance

Regular maintenance and inspection of the 4936170 ECM Bracket can help to ensure its longevity and optimal performance. Common issues may include signs of wear or damage to the bracket, which can affect its ability to secure the ECM effectively. Addressing these issues promptly can prevent more significant problems down the line. Maintenance tips include checking the bracket for any signs of corrosion, ensuring that it remains securely fastened, and verifying that the ECM is properly seated within the bracket 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its product range, which is designed to meet the demanding requirements of commercial vehicle operators worldwide 8.

Electronic Control Module Bracket (Part 4936170) Compatibility with Cummins Engines

The Electronic Control Module (ECM) Bracket, identified by part number 4936170, is a critical component in the installation and operation of various Cummins engines. This bracket is designed to securely hold the ECM, ensuring proper alignment and functionality of the engine’s electronic control system. Below is a detailed description of its compatibility with specific Cummins engines:

ISB Series Engines

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

The ISB series engines are known for their robust performance and reliability. The ECM Bracket 4936170 is engineered to fit seamlessly with these engines, providing a stable platform for the ECM. This ensures that the engine’s electronic systems operate efficiently, contributing to overall performance and longevity.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines are designed for heavy-duty applications, often found in construction and agricultural equipment. The ECM Bracket 4936170 is compatible with these engines, ensuring that the ECM is securely mounted. This is crucial for maintaining the integrity of the engine’s electronic control systems, especially under demanding conditions.

ISD Series Engines

- ISD4.5 CM2220 D108

The ISD series engines are engineered for durability and efficiency. The ECM Bracket 4936170 is specifically designed to fit the ISD4.5 CM2220 D108, providing a reliable mounting solution for the ECM. This ensures that the engine’s electronic systems are properly aligned and secured, contributing to optimal performance.

QSB Series Engines

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

The QSB series engines are widely used in a variety of applications, from industrial to marine. The ECM Bracket 4936170 is compatible with these engines, ensuring that the ECM is securely mounted. This is essential for maintaining the accuracy and reliability of the engine’s electronic control systems, which are critical for performance and efficiency.

By providing a secure and stable mounting solution for the ECM, the 4936170 bracket ensures that the engine’s electronic systems function correctly, contributing to the overall reliability and performance of the engine 9.

Role of Part 4936170 Electronic Control Module Bracket in Engine Systems

In modern engine systems, the Electronic Control Module (ECM) is a pivotal component that manages various engine functions through electronic signals. The ECM requires a secure and stable mounting solution to ensure optimal performance and longevity. This is where the Electronic Control Module Bracket, specifically part 4936170, comes into play.

The 4936170 bracket is designed to provide a robust and reliable mounting platform for the ECM. It ensures that the module remains firmly in place, even under the vibrations and harsh conditions typical of engine environments. This stability is essential for maintaining the integrity of the electrical connections between the ECM and other engine components.

Moreover, the bracket facilitates easy access to the ECM for maintenance and diagnostic purposes. Its design allows for straightforward installation and removal, which is beneficial during routine checks or when upgrades to the engine control system are necessary.

Additionally, the 4936170 bracket plays a role in thermal management. By securely holding the ECM in a designated location, it helps in dissipating heat generated by the module. This is important for preventing overheating, which can lead to malfunctions or reduced efficiency of the engine control system.

In summary, the 4936170 Electronic Control Module Bracket is an integral component in engine systems, ensuring the ECM is securely mounted, easily accessible, and effectively managed thermally. Its role in supporting the ECM contributes to the overall reliability and performance of the engine control system 10.

Conclusion

The 4936170 Electronic Control Module Bracket is a critical component in the operation and maintenance of Cummins engines. Its robust design, compatibility with various engine models, and role in ensuring the stability and protection of the ECM make it an essential part of the engine’s electronic control system. Proper installation, regular maintenance, and understanding its compatibility with specific Cummins engines are key to maximizing the performance and reliability of the engine.

-

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Bennett, S., & Norman, I.A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Lakshminarayanan, P.A., & Nayak, N.S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Bennett, S., & Norman, I.A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P.A., & Nayak, N.S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Product Compatibility. Retrieved from Cummins Official Website.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.