This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

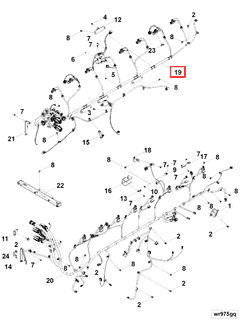

The 5419575 Electronic Control Module Wiring Harness is a specialized component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This wiring harness is integral to the operation of commercial trucks, facilitating the communication and power distribution necessary for the vehicle’s electronic systems to function efficiently.

Basic Concepts

Electronic Control Module Wiring Harnesses are fundamental to modern vehicle electronics and engine management systems. They consist of a network of wires and connectors that link various electronic components within the vehicle. These harnesses enable the transmission of data, power, and signals between the Electronic Control Module (ECM) and other electronic systems, ensuring coordinated operation and optimal performance 1.

Function and Operation

The 5419575 Electronic Control Module Wiring Harness operates within the truck’s electronic system by providing a structured pathway for electrical signals and power. It interacts with the ECM, which is the brain of the truck’s engine management system, and other electronic components. This interaction allows for the precise control of engine functions, monitoring of performance metrics, and the implementation of safety protocols 2.

Purpose of the 5419575 Electronic Control Module Wiring Harness

The specific role of the 5419575 Wiring Harness in a truck’s operation includes facilitating data transmission between the ECM and various sensors and actuators, distributing power to electronic components, and processing signals to ensure the engine and other systems operate within specified parameters. This ensures the truck’s electronic systems can communicate effectively, leading to enhanced performance and reliability 3.

Key Features

The 5419575 Wiring Harness is characterized by its robust design and the use of high-quality materials, which contribute to its performance and durability. It is engineered to withstand the harsh conditions typical of commercial truck environments, including exposure to vibrations, temperature extremes, and moisture. Unique attributes such as corrosion-resistant connectors and flexible yet durable wiring enhance its reliability and longevity 4.

Benefits

The advantages provided by the 5419575 Wiring Harness include improved reliability in data transmission and power distribution, increased efficiency in engine management, and seamless integration with modern truck technologies. These benefits contribute to the overall performance and longevity of the truck, reducing downtime and maintenance costs.

Installation Considerations

When installing the 5419575 Wiring Harness, it is important to follow guidelines and best practices to ensure compatibility with various truck models and systems. Proper installation involves careful routing of the harness to avoid damage from heat, abrasion, or sharp edges, and secure attachment of all connectors to prevent electrical issues.

Troubleshooting and Maintenance

Diagnosing and resolving common issues with the 5419575 Wiring Harness may involve checking for loose connections, inspecting wires for damage, and ensuring all components are functioning as intended. Regular maintenance, such as cleaning connectors and inspecting the harness for signs of wear or damage, can help ensure longevity and optimal performance.

Safety and Compliance

The use of the 5419575 Wiring Harness in commercial trucks is subject to safety standards and regulatory compliance to ensure the protection of operators and the reliability of the vehicle. Adherence to these standards is crucial for the safe operation of the truck and the protection of its electronic systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the 5419575 Electronic Control Module Wiring Harness.

Cummins Electronic Control Module Wiring Harness (Part 5419575)

The Cummins Electronic Control Module Wiring Harness (Part 5419575) is a critical component designed to ensure seamless electrical connectivity and communication between the engine’s Electronic Control Module (ECM) and various sensors, actuators, and other electronic components. This wiring harness is engineered to fit seamlessly with several Cummins engine models, ensuring compatibility and reliability.

QSK95 Engine

The QSK95 engine, known for its robust performance and efficiency, integrates the wiring harness to facilitate precise control and monitoring of engine functions. The harness is designed to withstand the demanding conditions of heavy-duty applications, ensuring that the ECM can effectively manage engine performance, emissions, and diagnostics.

CM2350 Engine

The CM2350 engine, another high-performance model from Cummins, also utilizes the 5419575 wiring harness. This engine is often used in marine and industrial applications, where reliability and durability are paramount. The wiring harness ensures that the ECM can accurately read and respond to data from various sensors, maintaining optimal engine operation under diverse conditions.

K113 Engine

The K113 engine, part of Cummins’ lineup of medium-duty engines, is engineered for versatility and efficiency. The 5419575 wiring harness is integral to this engine’s operation, providing a reliable connection between the ECM and other electronic components. This ensures that the engine can perform efficiently while meeting stringent emissions standards.

Compatibility and Installation

The Cummins Electronic Control Module Wiring Harness (Part 5419575) is designed to be compatible with the QSK95, CM2350, and K113 engines. Installation of this harness is straightforward, ensuring that technicians can quickly and accurately integrate it into the engine’s electrical system. The harness is built to last, with high-quality materials that resist wear and tear, ensuring long-term reliability and performance.

Understanding the Role of Part 5419575 Electronic Control Module Wiring Harness

The part 5419575 Electronic Control Module (ECM) Wiring Harness is an integral component in modern engine systems, facilitating seamless communication and power distribution between the ECM and various engine components. This wiring harness is meticulously designed to ensure reliable and efficient operation of the engine system.

Integration with Engine Components

-

Sensors and Actuators: The ECM Wiring Harness connects various sensors (such as the Mass Air Flow sensor, Oxygen sensor, and Manifold Absolute Pressure sensor) and actuators (like the fuel injectors, throttle body, and ignition coils) to the ECM. This connection allows the ECM to monitor engine conditions and make real-time adjustments for optimal performance.

-

Power Supply: It provides a consistent power supply to the ECM and other electronic components, ensuring they operate within specified parameters. This includes connections to the battery and the engine’s primary power circuits.

-

Grounding: Proper grounding is essential for the ECM to function correctly. The wiring harness includes multiple ground wires that connect to the engine block and chassis, ensuring a stable reference voltage for the ECM and other electronic components.

-

Communication Networks: In many modern engine systems, the ECM Wiring Harness is part of a Controller Area Network (CAN) bus system. This allows the ECM to communicate with other control modules in the vehicle, such as the Transmission Control Module (TCM) and the Anti-lock Braking System (ABS) module, enhancing overall vehicle performance and safety.

-

Diagnostic Capabilities: The harness incorporates connections for On-Board Diagnostics (OBD-II) systems, allowing mechanics to retrieve diagnostic trouble codes (DTCs) and perform thorough inspections of the engine system. This facilitates easier troubleshooting and maintenance.

-

Environmental Protection: The wiring harness is often encased in protective materials to shield the wires from engine heat, vibrations, and moisture. This ensures longevity and reliability in various driving conditions.

Conclusion

In summary, the 5419575 ECM Wiring Harness plays a significant role in the functionality and efficiency of engine systems by providing essential connections, power distribution, and communication pathways between the ECM and other critical components. Its robust design, compatibility with various Cummins engines, and integration into modern engine management systems make it a vital component for ensuring reliable and efficient engine operation.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.