This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

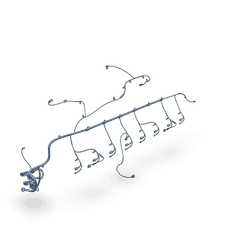

The 5504882 Electronic Control Module Wiring Harness is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its diesel engines and related components. This wiring harness plays a significant role in the operation of commercial trucks by facilitating the electrical connections necessary for the vehicle’s systems to function correctly.

Basic Concepts

Electronic Control Module (ECM) Wiring Harnesses are integral to a vehicle’s electrical system. They serve as the conduit through which the ECM communicates with various sensors and actuators throughout the vehicle. This communication is vital for the proper operation of the truck, as it allows the ECM to monitor and control different systems based on the data received from sensors 1.

Purpose and Functionality

The 5504882 Electronic Control Module Wiring Harness is designed to enable seamless communication between the ECM and the truck’s sensors and actuators. By providing a structured pathway for electrical signals, it ensures that the ECM can effectively manage the engine’s performance, fuel efficiency, and other critical functions. This harness is a cornerstone in the truck’s electrical architecture, allowing for precise control and monitoring of the vehicle’s operations 2.

Key Features

The 5504882 Electronic Control Module Wiring Harness is characterized by its robust design and the quality materials used in its construction. It is engineered to withstand the harsh conditions typically encountered in commercial trucking, including exposure to vibrations, temperature fluctuations, and moisture. Its design incorporates features that enhance its durability and performance, ensuring reliable operation over the vehicle’s lifespan.

Benefits

The implementation of the 5504882 Electronic Control Module Wiring Harness in commercial trucks offers several advantages. It contributes to improved engine performance by ensuring that the ECM receives accurate and timely data from sensors. This leads to optimized fuel efficiency and enhances the overall reliability of the truck’s electrical system. The harness’s design also supports easier diagnosis and troubleshooting of electrical issues, reducing downtime and maintenance costs.

Troubleshooting and Maintenance

To maintain the optimal performance of the 5504882 Electronic Control Module Wiring Harness, regular inspections and maintenance are recommended. This includes checking for signs of wear or damage, ensuring all connections are secure, and addressing any issues promptly. Following manufacturer guidelines for maintenance and troubleshooting can help prevent more serious electrical problems and extend the lifespan of the harness.

Integration with Truck Systems

The 5504882 Electronic Control Module Wiring Harness is designed to integrate seamlessly with various systems within the truck, including the engine management system, transmission control module, and diagnostic systems. This integration allows for comprehensive monitoring and control of the vehicle’s operations, enhancing overall performance and efficiency.

Safety Considerations

When installing, maintaining, or operating the 5504882 Electronic Control Module Wiring Harness, it is important to adhere to manufacturer guidelines and industry standards. This ensures the safety and reliability of the electrical system. Proper handling and maintenance of the harness are crucial to prevent electrical faults that could lead to safety hazards.

Environmental Impact

The 5504882 Electronic Control Module Wiring Harness contributes to the environmental performance of commercial trucks by supporting improved fuel efficiency and reduced emissions. By enabling precise control over engine operations, it helps minimize fuel consumption and lower the truck’s carbon footprint.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is committed to innovation, quality, and sustainability, providing reliable and efficient solutions for its customers.

Compatibility with Cummins Engines

QSK95

The QSK95 engine, known for its robust performance and efficiency, integrates the 5504882 wiring harness to maintain optimal electronic control. This engine is often used in heavy-duty applications, and the wiring harness ensures that all electronic signals are transmitted accurately and efficiently, contributing to the engine’s overall performance and reliability.

CM2350

The CM2350 engine, another high-performance model from Cummins, also utilizes the 5504882 wiring harness. This engine is designed for demanding applications, and the wiring harness plays a crucial role in managing the complex electronic systems that control engine functions. By ensuring reliable connectivity, the harness helps maintain the engine’s efficiency and responsiveness.

K113

The K113 engine, part of Cummins’ lineup of industrial and power generation engines, is another beneficiary of the 5504882 wiring harness. This engine is often used in power generation and industrial applications, where consistent and reliable performance is essential. The wiring harness ensures that the ECM can effectively communicate with all necessary components, facilitating smooth operation and reducing the risk of electronic failures.

Grouping for Enhanced Understanding

When considering the QSK95, CM2350, and K113 engines together, it is evident that the 5504882 wiring harness is a versatile component designed to meet the needs of various high-performance and heavy-duty applications. Each engine, while distinct in its specific use case, relies on the wiring harness to maintain the integrity of its electronic systems. This ensures that regardless of the engine model, the wiring harness provides a reliable and efficient means of managing electronic communications and power distribution.

Conclusion

The 5504882 Electronic Control Module Wiring Harness by Cummins is a critical component in the operation of commercial trucks. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of performance, efficiency, and reliability make it an essential part of the truck’s electrical system. Regular maintenance and adherence to safety guidelines are crucial to ensure the harness’s optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.