This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4099004 Engine Crank Shaft is a vital component in the operation of commercial trucks. It is designed to facilitate the conversion of linear piston motion into rotational motion, which is fundamental for the engine’s operation. This component is integral to the efficient and reliable performance of the truck’s engine.

Basic Concepts of Engine Crank Shafts

An engine crank shaft is a mechanical part that plays a central role in the operation of an internal combustion engine. Its primary functions include converting the reciprocating motion of the pistons into rotational motion, which drives the vehicle’s wheels. The crank shaft is connected to the pistons via connecting rods and rotates within the engine block, transferring power generated by the combustion process to the transmission system 1.

Purpose of the Cummins 4099004 Engine Crank Shaft

The Cummins 4099004 Engine Crank Shaft serves a specific role in the operation of a truck. It is responsible for converting the linear motion of the pistons into rotational motion, which is then transmitted to the transmission system. This conversion is achieved through the strategic placement of crank pins and journals along the length of the crank shaft. The efficient operation of this component ensures smooth and consistent power delivery, which is essential for the truck’s performance.

Key Features

The Cummins 4099004 Engine Crank Shaft is characterized by several key features that enhance its performance and durability. Its design incorporates precision-machined journals and crank pins, which ensure smooth operation and minimal friction. The material used in its construction is typically high-strength alloy, which provides the necessary durability and resistance to wear. Additionally, the crank shaft may feature counterweights to balance the rotating assembly, reducing vibrations and enhancing engine smoothness.

Benefits

The Cummins 4099004 Engine Crank Shaft offers several benefits that contribute to improved engine efficiency, reliability, and longevity. Its high-strength material and precision machining result in reduced friction and wear, leading to enhanced engine performance. The balanced design minimizes vibrations, which can extend the lifespan of both the crank shaft and other engine components. Furthermore, the efficient conversion of piston motion into rotational motion ensures consistent power delivery, which is essential for the reliable operation of commercial trucks.

Installation Process

Installing the Cummins 4099004 Engine Crank Shaft requires careful attention to detail and adherence to best practices. The process typically involves the following steps: ensuring the engine block is clean and free of debris, aligning the crank shaft with the main bearings, and securing it in place using the appropriate fasteners. It is important to verify that all components are properly aligned and that there is no excessive play or misalignment, as this can lead to premature wear and reduced performance.

Common Issues and Troubleshooting

Engine crank shafts can encounter several common issues, including wear, misalignment, and balance problems. Symptoms of these issues may include increased engine vibrations, reduced performance, or unusual noises. Troubleshooting these problems often involves inspecting the crank shaft for signs of wear or damage, checking the alignment of the crank shaft within the engine block, and ensuring that the balance weights are intact and properly positioned. Addressing these issues promptly can help maintain the engine’s performance and longevity.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 4099004 Engine Crank Shaft, regular maintenance is recommended. This includes conducting periodic inspections for signs of wear or damage, ensuring that the crank shaft is properly lubricated, and addressing any issues promptly. Additionally, following the manufacturer’s recommended maintenance schedule for the engine can help prevent issues related to the crank shaft and other components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications.

Cummins Engine Crank Shaft 4099004 Compatibility

The Cummins Engine Crank Shaft part number 4099004 is a critical component that fits seamlessly into various Cummins engine models. This crankshaft is designed to ensure smooth engine operation and is compatible with the following engines:

K38 Series

The K38 series engines benefit from the robust design of the 4099004 crankshaft. This part is engineered to handle the specific demands of the K38 engines, ensuring durability and performance.

KTA38GC CM558

The KTA38GC CM558 engine is another model that integrates the 4099004 crankshaft. This engine is known for its reliability and efficiency, and the crankshaft plays a pivotal role in maintaining these characteristics.

QSK38 Series

The QSK38 series engines, including the QSK38 CM2150 MCRS and QSK38 CM850 MCRS, are designed to perform under demanding conditions. The 4099004 crankshaft is integral to these engines, providing the necessary strength and precision to support high-performance operations.

The compatibility of the 4099004 crankshaft across these engines underscores its versatility and importance in ensuring the engines’ optimal performance.

Integration of Part 4099004 Engine Crank Shaft in Engine Systems

The part 4099004 Engine Crank Shaft is a fundamental component in the orchestration of an engine’s operation, specifically within the context of the provided components. Its role is to convert the reciprocating motion of the pistons into rotational force, which is then transmitted to the transmission system.

In the Block and Cylinder assembly, the crankshaft is housed within the lower portion of the engine block, aligning with the cylinder bores. It interacts with the pistons via connecting rods, which are pivotal in transferring the force generated by the combustion process within the cylinders.

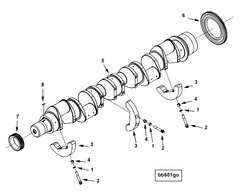

As part of the Crankshaft Assembly, the 4099004 Engine Crank Shaft is often pre-assembled with main bearings and counterweights. This assembly is then integrated into the engine block, ensuring smooth operation and balancing the forces produced by the pistons’ movement.

Within the Engine itself, the crankshaft is a central figure, connecting to various components such as the flywheel or flexplate, which in turn connects to the transmission. This connection is vital for the transfer of power from the engine to the drivetrain.

In the context of the Engine Crankshaft and its assembly, the 4099004 part ensures that the rotational motion is consistent and balanced, reducing vibrations and wear on the engine components.

When considering the Short Block Assembly and the Short Block Assy -K38, the crankshaft is an integral part of these assemblies. It is responsible for the mechanical linkage between the pistons and the transmission, facilitating the engine’s power output.

The seamless integration of the 4099004 Engine Crank Shaft with these components underscores its importance in the efficient and reliable operation of the engine. Its design and construction are tailored to withstand the high stresses and forces encountered during engine operation, ensuring durability and performance.

Conclusion

The Cummins 4099004 Engine Crank Shaft is a critical component in the operation of commercial trucks, ensuring the efficient conversion of piston motion into rotational force. Its high-strength material, precision machining, and balanced design contribute to enhanced engine performance, reliability, and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are essential for maintaining the optimal performance of this component.

-

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.