This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

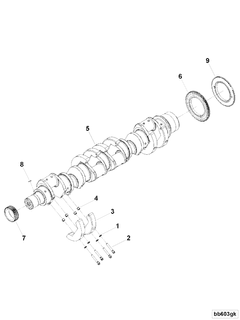

The 3648630 Engine Crankshaft, manufactured by Cummins, is a critical component in the commercial truck industry, contributing to the efficient and reliable performance of engines.

Basic Concepts of an Engine Crankshaft

An engine crankshaft converts the reciprocating motion of the pistons into rotational motion, a fundamental process in internal combustion engines. Connected to the pistons via connecting rods, the crankshaft rotates as the pistons move, transmitting rotational motion to the transmission system and ultimately driving the vehicle’s wheels.

Role of the 3648630 Engine Crankshaft in Truck Operation

This Cummins part facilitates the conversion of linear piston motion into rotational motion, interacting with various engine components such as pistons, connecting rods, and the flywheel. Its design and material properties are tailored to withstand the high stresses and loads encountered in heavy-duty truck applications.

Key Features of the 3648630 Engine Crankshaft

This part is characterized by precision machining for smooth operation, a balanced design to minimize vibrations, and the use of high-strength materials to withstand the rigors of commercial truck use. It may also feature advanced coatings or treatments to improve wear resistance and longevity.

Benefits of Using the 3648630 Engine Crankshaft

Utilizing this part in a commercial truck engine offers advantages such as improved engine efficiency due to its precise manufacturing, enhanced reliability under heavy-duty conditions, and increased longevity thanks to its robust design and materials. Its performance contributes to the overall efficiency and durability of the engine.

Installation and Integration

Proper installation and integration of this part into a truck’s engine system require careful attention to detail. Ensuring correct alignment with the engine block and proper installation of all connecting components, such as the pistons and connecting rods, is essential. Following manufacturer guidelines for torque specifications and clearances is crucial for optimal performance and longevity.

Troubleshooting Common Issues

Common problems associated with engine crankshafts can include wear, misalignment, or damage from excessive stress. Troubleshooting steps for this model may involve inspecting the crankshaft for signs of wear or damage, checking alignment with the engine block, and ensuring that all connecting components are in good condition. Regular maintenance and inspections can help identify and address issues before they lead to more significant problems.

Maintenance Practices

To ensure the longevity and optimal performance of this part, recommended maintenance practices include regular inspections for wear or damage, proper lubrication to reduce friction and wear, and following manufacturer guidelines for maintenance intervals. Keeping the engine clean and free of contaminants can also contribute to the crankshaft’s longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines and powertrain solutions designed to meet the demanding requirements of commercial and industrial applications.

Engine Crankshaft Compatibility with Cummins Engines

This part is compatible with several Cummins engine models, including GTA38 G CMEICS G116C, K38, KTA38GC CM558, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS. Its design ensures smooth operation and reliability across various engine configurations, tailored to match the torque and rotational speed requirements of these engines.

Role of Part 3648630 Engine Crankshaft in Engine Systems

This part is integral to the operation of the engine system, working in concert with several key components to ensure efficient and reliable performance.

Interaction with the Cylinder Block

The crankshaft is housed within the cylinder block, where it rotates to convert the linear motion of the pistons into rotational motion. This interaction is fundamental as the crankshaft’s journals fit into the main bearings within the cylinder block, allowing for smooth rotation and minimal friction.

Coordination with Pistons and Connecting Rods

As the pistons move up and down within the cylinders, they are connected to the crankshaft via connecting rods. The crankshaft’s throws interact with the connecting rods, translating the pistons’ linear motion into rotational force. This rotational motion is then transmitted to other engine components.

Relationship with the Engine Block

The engine block serves as the structural foundation of the engine, encapsulating the cylinder block and supporting the crankshaft. The crankshaft is secured to the engine block through main bearing caps, which are bolted to the block, ensuring stability and alignment during operation.

Contribution to Overall Engine Function

Within the engine system, the crankshaft’s role extends beyond mere motion conversion. It is also responsible for maintaining the engine’s balance, reducing vibrations, and ensuring smooth operation. The crankshaft’s design, including counterweights and harmonic balancing, plays a significant part in achieving this balance.

Conclusion

In summary, the 3648630 Engine Crankshaft is a pivotal component that interacts closely with the cylinder block, pistons, connecting rods, and engine block to facilitate the engine’s operation. Its precise engineering and integration within the engine system are essential for the engine’s performance and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.