This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

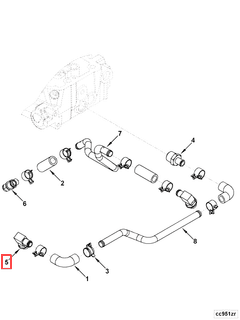

The 3979410 Elbow Hose Connector, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This connector facilitates the transfer of fluids within the truck’s system, ensuring efficient operation and reliability. Cummins, a well-regarded name in the automotive industry, produces this component with a focus on durability and performance, contributing to the overall functionality of commercial vehicles.

Basic Concepts and Functionality

An Elbow Hose Connector is a fitting used to join hoses at an angle, allowing for fluid transfer in systems where space constraints or design requirements necessitate a change in direction. The 3979410 model by Cummins operates on the basic principle of providing a secure and leak-proof connection between hoses, enabling the smooth flow of fluids such as coolant, fuel, or hydraulic fluid. Its design and functionality are integral to maintaining the integrity and efficiency of the truck’s fluid systems 1.

Purpose and Role in Truck Operation

The 3979410 Elbow Hose Connector serves a specific purpose in the operation of a truck by ensuring the reliable transfer of fluids between components. It contributes to the efficiency and reliability of the truck’s systems by providing a durable and secure connection point that can withstand the pressures and temperatures associated with fluid transfer in commercial vehicles. This component is integral to maintaining the performance and longevity of the truck’s fluid systems 2.

Key Features

The 3979410 Elbow Hose Connector boasts several key features that enhance its performance and durability. Constructed from high-quality materials, it is designed to resist corrosion and wear, ensuring long-term reliability. Its design includes precise fitting dimensions and a robust construction that facilitates easy installation and secure connections. Additionally, the connector may feature unique characteristics such as reinforced joints or specialized coatings to further improve its performance in demanding environments 3.

Benefits

The benefits of using the 3979410 Elbow Hose Connector include improved fluid flow, enhanced durability, and ease of installation. These advantages contribute to the overall performance and maintenance of the truck by ensuring efficient fluid transfer, reducing the risk of leaks, and simplifying the replacement or upgrade process. The connector’s design also aids in minimizing maintenance requirements, thereby supporting the truck’s operational efficiency and reliability.

Installation and Compatibility

Proper installation of the 3979410 Elbow Hose Connector is vital to ensure its effectiveness and the integrity of the truck’s fluid systems. Guidelines for installation include verifying compatibility with existing system components, ensuring a secure fit, and following manufacturer recommendations for torque settings and connection procedures. Correct installation procedures are important to prevent leaks, ensure optimal performance, and maintain the safety and efficiency of the truck’s systems.

Troubleshooting and Maintenance

Common issues with the 3979410 Elbow Hose Connector may include leaks, corrosion, or wear over time. Troubleshooting steps involve inspecting the connector for signs of damage, ensuring proper installation, and replacing the component if necessary. Maintenance tips to ensure longevity and optimal performance include regular inspection for wear or corrosion, cleaning the connector and surrounding areas, and following manufacturer guidelines for maintenance and replacement intervals.

Safety Considerations

When working with the 3979410 Elbow Hose Connector, it is important to observe safety precautions to ensure personal safety and system integrity. This includes wearing appropriate personal protective equipment, ensuring the system is depressurized before beginning work, and following all manufacturer guidelines for installation, maintenance, and troubleshooting. Taking these precautions helps prevent accidents and ensures the safe and efficient operation of the truck’s fluid systems.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, known for its commitment to quality, innovation, and performance. With a rich history of producing reliable and efficient components for commercial vehicles, Cummins has established a strong reputation for excellence. Their focus on research and development, coupled with a dedication to customer satisfaction, underscores their position as a leader in the industry, providing components that enhance the performance and reliability of commercial trucks.

3979410 Elbow Hose Connector Compatibility with Cummins Engines

The 3979410 Elbow Hose Connector, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral in ensuring the proper routing and connection of hoses within the engine’s cooling and exhaust systems. Below is a detailed breakdown of the engines with which this part is compatible:

B Series Engines

- B3.3

- B6.7 CM2670

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISB6.7 CM2350 B101

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

ISL Series Engines

- ISL G CM2180

L GAS PLUS Series Engines

- L GAS PLUS CM556

QSB Series Engines

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

This part is engineered to meet the specific requirements of each engine model, ensuring a secure and reliable connection. It is essential for maintaining the integrity of the engine’s systems and preventing leaks or disconnections that could lead to performance issues or damage.

Role of 3979410 Elbow Hose Connector in Engine Systems

The 3979410 Elbow Hose Connector is integral to several engine systems, facilitating efficient fluid transfer and maintaining system integrity.

Air Compressor System

In the air compressor system, the 3979410 Elbow Hose Connector directs the flow of compressed air. It ensures that the air moves from the compressor to the distribution points without leakage, enhancing the system’s overall performance and reliability.

Cabin Heater Plumbing

Within the cabin heater plumbing, this connector plays a key role in routing coolant from the engine to the heater core. It ensures a consistent flow of heated coolant, which is essential for maintaining comfortable cabin temperatures during operation.

Compressor Coolant Arrangement

The 3979410 Elbow Hose Connector is also vital in the compressor coolant arrangement. It helps manage the coolant flow to and from the compressor, ensuring that the compressor remains within optimal operating temperatures. This contributes to the longevity and efficiency of the compressor.

Compressor Coolant Plumbing

In the compressor coolant plumbing, the connector ensures that coolant is efficiently circulated through the system. This is important for dissipating heat generated by the compressor, thereby preventing overheating and potential damage to the compressor and surrounding components.

Conclusion

The 3979410 Elbow Hose Connector by Cummins is a critical component in the operation of commercial trucks, ensuring efficient and reliable fluid transfer across various engine systems. Its robust design, compatibility with a wide range of Cummins engines, and the benefits it offers in terms of durability and ease of installation make it an essential part for maintaining the performance and reliability of commercial vehicles. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the effectiveness of this connector and ensuring the overall efficiency of the truck’s fluid systems.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.