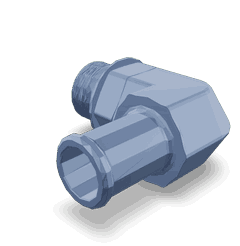

5318057

Elbow Hose Coupling

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5318057 Elbow Hose Coupling, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of high-quality parts that enhance the performance and reliability of commercial vehicles. This part is integral to fluid transfer systems, facilitating the efficient and secure connection of hoses at an angle. It ensures the smooth operation of various fluid systems within trucks, contributing to overall vehicle performance.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees. Its primary function is to allow for flexible and secure connections in fluid systems, accommodating the spatial constraints and design requirements of the vehicle. By enabling hoses to connect at an angle, elbow hose couplings help maintain the integrity of fluid flow, reduce stress on the hoses, and enhance the overall efficiency of the system 1.

Purpose of the 5318057 Elbow Hose Coupling

The 5318057 Elbow Hose Coupling plays a specific role in the operation of commercial trucks by connecting hoses in various fluid systems such as coolant, fuel, and hydraulic lines. This coupling ensures that fluids are transferred efficiently and reliably, even when the hoses need to be routed around obstacles or through tight spaces. Its application in these systems helps maintain the performance and longevity of the truck’s fluid transfer mechanisms 2.

Key Features

The 5318057 Elbow Hose Coupling is designed with several features that enhance its performance and durability. It is constructed from materials that offer excellent corrosion resistance, ensuring longevity in harsh operating environments. The coupling is rated for specific pressure levels, making it suitable for use in high-pressure systems. Additionally, it is compatible with various types of hoses, providing versatility in different applications. These design elements contribute to the coupling’s reliability and effectiveness in commercial truck fluid systems 3.

Benefits

Using the 5318057 Elbow Hose Coupling offers several advantages. It improves system efficiency by ensuring a secure and leak-free connection between hoses. The design of the coupling reduces the risk of leaks, which can lead to system failures and downtime. Additionally, the coupling is easy to install and maintain, making it a practical choice for fleet managers and technicians. Its robust construction and compatibility with different hose types further enhance its appeal for use in commercial trucks.

Installation Process

Proper installation of the 5318057 Elbow Hose Coupling involves several steps to ensure a reliable connection. Begin by preparing the hoses, ensuring they are clean and free of debris. Align the coupling with the hoses, making sure it is positioned correctly to achieve the desired angle. Secure the coupling using the appropriate methods, such as clamps or fittings, to ensure a tight and stable connection. Following these steps will help maintain the integrity of the fluid system and prevent leaks.

Troubleshooting Common Issues

Typical problems that may arise with elbow hose couplings include leaks or disconnections. To address these issues, first, inspect the coupling and hoses for any signs of damage or wear. Ensure that the coupling is properly aligned and secured. If a leak is detected, check the connection points for tightness and make any necessary adjustments. Regular inspections and maintenance can help identify and resolve issues before they lead to system failures.

Maintenance Tips

To prolong the lifespan of the 5318057 Elbow Hose Coupling, regular maintenance is recommended. Inspect the coupling and hoses at regular intervals for signs of wear, corrosion, or damage. Clean the coupling and surrounding areas to remove any buildup that could affect performance. If any parts show signs of significant wear or damage, consider replacement to prevent potential system failures. Adhering to these maintenance practices will help ensure the continued reliability of the fluid transfer system.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s extensive product range includes components like the 5318057 Elbow Hose Coupling, reflecting its commitment to providing reliable and high-performance parts for commercial trucks. Cummins’ focus on quality and customer satisfaction underscores its position as a trusted manufacturer in the industry.

Elbow Hose Coupling 5318057 Compatibility with Cummins Engines

The Elbow Hose Coupling 5318057, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring a secure and leak-free connection for hoses. Below is a detailed overview of the engines with which this part is compatible.

ISB Series

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The ISB series engines are known for their robust design and efficiency. The 5318057 Elbow Hose Coupling is engineered to fit seamlessly with these engines, providing a reliable connection for various hoses.

QSB Series

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The QSB series engines are designed for durability and performance in demanding environments. The 5318057 Elbow Hose Coupling is compatible with these engines, ensuring that hose connections remain secure and leak-proof.

Other Series

- B3.3

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- ISBE CM2150

- ISBE4 CM850

- L8.9 CM2670 L134C

These engines, while less common, are still part of the Cummins lineup and benefit from the reliable performance of the 5318057 Elbow Hose Coupling. This part ensures that hose connections are secure, reducing the risk of leaks and maintenance issues.

The 5318057 Elbow Hose Coupling is a versatile and essential component for maintaining the integrity of hose connections across a wide range of Cummins engines. Its compatibility with both the ISB and QSB series, as well as other models, makes it a valuable part for technicians and operators alike.

Role of Part 5318057 Elbow Hose Coupling in Engine Systems

The part 5318057 Elbow Hose Coupling is instrumental in facilitating the connection and redirection of fluid pathways within various engine systems. Its application across different components ensures efficient operation and maintenance of the systems involved.

Air Compressor

In the air compressor system, the Elbow Hose Coupling is employed to connect the air intake hose to the compressor unit. This connection allows for a smooth transition of air flow, minimizing leaks and ensuring that the compressor receives a consistent supply of air necessary for its operation.

Cabin Heater Plumbing

Within the cabin heater plumbing, the Elbow Hose Coupling plays a significant role in redirecting coolant flow from the engine to the heater core. This setup ensures that the coolant circulates effectively through the heater core, providing warm air to the vehicle’s cabin. The coupling’s design helps in managing the space constraints typically found in vehicle designs, allowing for a more compact and efficient plumbing layout.

Compressor Coolant Arrangement

For the compressor coolant arrangement, the Elbow Hose Coupling is used to connect the coolant lines that supply and return fluid to and from the compressor. This ensures that the compressor remains at an optimal operating temperature, enhancing its efficiency and longevity. The coupling’s ability to change direction allows for a more straightforward routing of coolant lines, reducing the risk of kinks or stress on the hoses.

Compressor Coolant Plumbing

In the compressor coolant plumbing, the Elbow Hose Coupling is essential for connecting various sections of the coolant lines. It enables the system to navigate around other components and obstacles within the engine bay, ensuring a smooth and uninterrupted flow of coolant. This is particularly important in high-performance engines where maintaining optimal compressor temperature is vital for performance and reliability.

Fuel Module Coolant Plumbing

The Elbow Hose Coupling is also utilized in the fuel module coolant plumbing to connect the coolant lines that regulate the temperature of the fuel module. By ensuring a secure and leak-free connection, the coupling helps maintain the integrity of the coolant system, which is essential for the proper functioning of the fuel module. This, in turn, contributes to the overall efficiency and performance of the engine.

Conclusion

The 5318057 Elbow Hose Coupling is a critical component in the fluid transfer systems of commercial trucks, ensuring efficient and reliable connections in various applications. Its robust design, compatibility with different hose types, and ease of installation make it a valuable asset for fleet managers and technicians. Regular maintenance and proper installation are essential to maximize the performance and longevity of this Cummins part. Its versatility and compatibility with a wide range of Cummins engines further underscore its importance in maintaining the integrity of hose connections across different engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.