This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

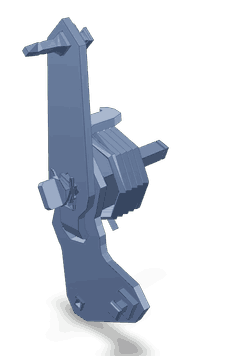

The Bell Crank Lever 3931569, manufactured by Cummins, is a critical component used in commercial trucks. This article provides an overview of the Bell Crank Lever, its function, key features, benefits, and maintenance suggestions.

Basic Concepts of Bell Crank Lever

A Bell Crank Lever is a type of lever that changes the direction of a force applied to it. It consists of a rigid beam pivoted at one point, with forces applied at two other points. The lever amplifies or redirects the force, making it useful in various mechanical systems 1.

Function of Bell Crank Lever 3931569 in Truck Operation

The Bell Crank Lever 3931569 plays a role in the mechanical systems of commercial trucks by redirecting and amplifying forces. It is commonly used in linkage systems to convert linear motion into rotational motion or vice versa, facilitating the operation of various truck components.

Key Features

- Constructed from durable materials to withstand the rigors of commercial truck use.

- Designed for precise force transmission and reliable operation.

- Engineered to integrate seamlessly with other truck components.

- Meets industry standards for quality and performance.

Benefits

- Enhances the efficiency of force transmission in mechanical systems.

- Contributes to the smooth operation of truck components.

- Durable construction ensures long-term reliability.

- Designed to reduce maintenance requirements and downtime.

Troubleshooting and Maintenance

Regular inspection of the Bell Crank Lever 3931569 is recommended to ensure it remains in good working condition. Look for signs of wear, corrosion, or damage. Lubrication of pivot points may be necessary to ensure smooth operation. If any issues are detected, consult the manufacturer’s guidelines for repair or replacement 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships.

Bell Crank Lever 3931569 in Cummins Engines

The Bell Crank Lever part number 3931569, manufactured by Cummins, is an integral component in several of their engine models. This part is designed to facilitate the transfer of motion and force within the engine’s mechanisms, ensuring smooth and efficient operation.

Application in Cummins Engines

-

6B5.9 Series: In the 6B5.9 engines, the Bell Crank Lever 3931569 plays a role in the valve train system. It is typically used to actuate the valves, converting the rotational motion of the camshaft into the linear motion required for valve operation. This ensures that the engine’s valves open and close at the correct times, which is vital for maintaining engine performance and efficiency.

-

Other Cummins Models: While the 6B5.9 series is a primary example, the Bell Crank Lever 3931569 is also compatible with other Cummins engines that share similar design principles. These engines often feature a valve train system that relies on bell crank levers to manage the timing and force applied to the valves. The compatibility of this part across various models underscores its versatility and importance in Cummins’ engine architecture.

Role of Part 3931569 Bell Crank Lever in Engine Systems

The Bell Crank Lever, identified by part number 3931569, is an integral component in the modulation and control of various engine systems. Its primary function is to translate linear motion into rotational motion, or vice versa, which is essential for the precise operation of several engine components.

Interaction with the Throttle System

In the throttle system, the Bell Crank Lever is pivotal in converting the linear movement of the throttle pedal into rotational motion that adjusts the throttle plate. This conversion ensures that the airflow into the engine is modulated accurately, which directly influences the engine’s power output and responsiveness. The lever is typically connected to the throttle bracket, which secures the throttle body in place, allowing for smooth and consistent throttle operation.

Integration with the Throttle Bracket

The throttle bracket serves as a mounting point for the throttle body and is directly influenced by the Bell Crank Lever. When the driver presses the accelerator pedal, the lever engages with the bracket, causing the throttle plate to open. This action increases the airflow into the engine, resulting in higher RPMs and greater power. Conversely, releasing the pedal causes the lever to close the throttle plate, reducing airflow and engine speed.

Functionality within the Throttle Kit

In a comprehensive throttle kit, the Bell Crank Lever works in conjunction with other components to provide a seamless throttle response. The kit often includes the throttle body, throttle position sensor, and various linkage components. The lever ensures that the mechanical linkage between the pedal and the throttle body is efficient and responsive, contributing to the overall performance and drivability of the engine.

Enhanced Control and Precision

The incorporation of the Bell Crank Lever in these systems enhances control and precision. By providing a mechanical advantage, the lever allows for finer adjustments of the throttle plate, which is particularly beneficial in high-performance applications where throttle response can significantly impact engine performance. Additionally, the lever’s design helps in reducing pedal effort, making it easier for the driver to modulate engine power smoothly.

Conclusion

The Bell Crank Lever 3931569 by Cummins is a vital component in the operation of commercial trucks and various Cummins engines. Its role in redirecting and amplifying forces ensures the smooth and efficient operation of mechanical systems. Regular maintenance and inspection are essential to ensure the longevity and reliability of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.