3649828

Hydraulic Oil Transfer Tube

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

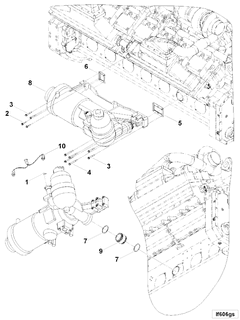

The Hydraulic Oil Transfer Tube (3649828) by Cummins is a component designed for use in the hydraulic systems of commercial trucks. Its purpose is to facilitate the movement of hydraulic fluid between various components within the system, ensuring smooth and efficient operation of hydraulic functions.

Basic Concepts of Hydraulic Oil Transfer Tubes

Hydraulic systems in commercial trucks are integral to the operation of various functions, including braking, steering, and suspension. Hydraulic oil serves as the medium through which force is transmitted within these systems. Transfer tubes play a role in directing the flow of this oil between different components, ensuring that hydraulic functions operate as intended 1.

Purpose of the 3649828 Hydraulic Oil Transfer Tube

The 3649828 Hydraulic Oil Transfer Tube is specifically designed to transfer hydraulic fluid within a truck’s hydraulic system. It connects various components, allowing for the seamless flow of oil, which is necessary for the actuation of hydraulic cylinders and other system parts. This transfer tube ensures that hydraulic pressure is maintained and distributed effectively throughout the system.

Key Features

The 3649828 Hydraulic Oil Transfer Tube is constructed with precision to meet the demands of commercial truck hydraulic systems. It is made from durable materials that resist corrosion and wear, ensuring longevity. The design includes features that enhance its performance, such as smooth internal passages for efficient fluid flow and secure connection points to prevent leaks 2.

Benefits

The use of the 3649828 Hydraulic Oil Transfer Tube offers several advantages. It contributes to improved hydraulic system efficiency by ensuring consistent fluid transfer. Additionally, its robust construction reduces the need for frequent maintenance, and its reliable performance enhances the overall dependability of the truck’s hydraulic system.

Installation and Integration

Proper installation of the 3649828 Hydraulic Oil Transfer Tube is vital for the optimal function of the hydraulic system. It should be integrated according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is correctly aligned with other system components. Attention to detail during installation helps prevent issues such as leaks or inefficient fluid transfer 3.

Troubleshooting Common Issues

Common problems with hydraulic oil transfer tubes may include leaks, blockages, or wear. These issues can arise from improper installation, debris in the hydraulic fluid, or natural wear over time. Troubleshooting steps may involve inspecting connections for tightness, cleaning or replacing filters to remove debris, and replacing worn components to restore system functionality.

Maintenance Tips

Routine maintenance of the 3649828 Hydraulic Oil Transfer Tube is important for its longevity and performance. This includes regular inspections for signs of wear or damage, cleaning the tube to remove any buildup, and ensuring that all connections remain tight. Adhering to recommended maintenance schedules helps prevent unexpected failures and extends the service life of the component.

Safety Considerations

When working with hydraulic systems and the 3649828 Hydraulic Oil Transfer Tube, it is important to observe safety protocols. This includes wearing appropriate personal protective equipment, ensuring that the system is depressurized before performing maintenance, and following all manufacturer guidelines to prevent accidents and ensure personal safety.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck markets with a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to excellence is reflected in its product offerings, including the 3649828 Hydraulic Oil Transfer Tube.

Application in Cummins Engines

- QSK60 CM500 and QSK60 CM850 MCRS

The Hydraulic Oil Transfer Tube is designed to fit seamlessly within the hydraulic systems of the QSK60 CM500 and QSK60 CM850 MCRS engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine, construction, and power generation.

- QSK60 CM850 MCRS

In the QSK60 CM850 MCRS engine, the Hydraulic Oil Transfer Tube plays a vital role in maintaining the integrity of the engine’s hydraulic circuits. This engine variant is equipped with advanced features that enhance operational efficiency and durability, making the proper functioning of hydraulic components crucial.

Importance of the Hydraulic Oil Transfer Tube

The Hydraulic Oil Transfer Tube is essential for the following reasons:

- Efficient Hydraulic Oil Flow

Ensures that hydraulic oil is transferred efficiently between different parts of the engine’s hydraulic system, maintaining optimal pressure and flow rates.

- System Integrity

Helps in maintaining the overall integrity of the hydraulic system by preventing leaks and ensuring that hydraulic oil is directed to the correct components.

- Performance and Reliability

Contributes to the overall performance and reliability of the engine by ensuring that hydraulic functions operate smoothly and without interruption.

Role of Part 3649828 Hydraulic Oil Transfer Tube in Engine Systems

The Hydraulic Oil Transfer Tube, part 3649828, is an essential component in the efficient operation of engine systems. It facilitates the movement of hydraulic oil from one part of the system to another, ensuring that all components receive the necessary lubrication and hydraulic pressure.

Interaction with the Filter

The Hydraulic Oil Transfer Tube works in conjunction with the filter to maintain the cleanliness of the hydraulic oil. As oil is transferred through the tube, it passes through the filter, which removes contaminants and debris. This ensures that the oil remains clean and effective, prolonging the life of the engine components and maintaining optimal performance.

Lubricating Oil System

In the lubricating oil system, the Hydraulic Oil Transfer Tube plays a key role in distributing oil to various engine parts. It ensures that bearings, pistons, and other moving components receive a consistent supply of lubricating oil. This reduces friction and wear, contributing to the smooth operation of the engine.

Lubricating Oil Filter

The tube is directly connected to the lubricating oil filter, which is responsible for purifying the oil before it is circulated throughout the engine. The efficient transfer of oil through the tube to the filter ensures that the filtration process is continuous and effective. This helps in maintaining the quality of the lubricating oil, which is vital for the engine’s longevity and performance.

Lubricating Oil Filter Head

The Hydraulic Oil Transfer Tube also interfaces with the lubricating oil filter head. This connection is crucial for regulating the flow of oil into the filter. The tube ensures that oil is delivered at the correct pressure and volume, allowing the filter head to operate efficiently. This regulation is important for maintaining the integrity of the filtration system and ensuring that the engine receives clean, pressurized oil.

Conclusion

In summary, the Hydraulic Oil Transfer Tube, part 3649828, is integral to the proper functioning of the engine’s hydraulic and lubrication systems. Its role in transferring oil ensures that filters, lubricating systems, and other components operate effectively, contributing to the overall efficiency and reliability of the engine.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series (2nd ed.). Springer.

↩ -

Bell, J. A. (2014). Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.