This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hydraulic Motor Return Line 4016422 by Cummins is a component designed for use in the hydraulic systems of commercial trucks. Its purpose is to facilitate the return of hydraulic fluid from the motor back to the reservoir, ensuring efficient operation and maintaining system pressure. This part is integral to the overall functionality of the hydraulic system, contributing to the reliable performance of the truck.

Basic Concepts of Hydraulic Motor Return Lines

Hydraulic systems in trucks operate by using pressurized fluid to transmit power and control various functions, such as braking, steering, and lifting. Return lines play a vital role in these systems by providing a pathway for the hydraulic fluid to travel back to the reservoir after it has performed its function. This circulation is crucial for maintaining consistent pressure and temperature within the system, which in turn ensures the hydraulic motor operates efficiently 1.

Purpose and Function

The Hydraulic Motor Return Line 4016422 is designed to return hydraulic fluid to the reservoir after it has been used by the motor. This process helps in maintaining the system’s pressure and temperature, which are critical for the efficient operation of the hydraulic motor. By ensuring a smooth return flow, the component contributes to the overall stability and performance of the truck’s hydraulic system 2.

Key Features

The 4016422 Hydraulic Motor Return Line is constructed from high-quality materials that offer durability and resistance to corrosion. Its design specifications include precise fittings and connections that ensure a secure and leak-free installation. Additionally, the line may feature unique attributes such as reinforced sections to withstand high pressure and flexible segments to accommodate movement within the truck’s chassis 3.

Benefits

The use of the 4016422 Hydraulic Motor Return Line offers several benefits. It enhances system efficiency by ensuring a consistent return flow of hydraulic fluid, which helps in maintaining optimal pressure levels. The high-quality construction reduces the need for frequent maintenance, leading to lower operational costs. Furthermore, its durable design contributes to the longevity of the hydraulic system, providing reliable performance over an extended period.

Installation and Integration

Proper installation of the 4016422 Hydraulic Motor Return Line is crucial for its effective function within the truck’s hydraulic system. It should be installed according to the manufacturer’s guidelines, ensuring all connections are secure and leak-free. Careful consideration should be given to the routing of the line to avoid sharp bends or kinks that could impede fluid flow. Additionally, it is important to verify that the line is compatible with the existing hydraulic components to ensure seamless integration.

Troubleshooting and Maintenance

Common issues with the 4016422 Hydraulic Motor Return Line may include leaks, blockages, or wear and tear. Regular inspection and maintenance can help identify these problems early. Maintenance practices should include checking for signs of corrosion, ensuring all connections are tight, and verifying that the line is free from obstructions. Prompt addressing of any issues will help maintain the efficiency and reliability of the hydraulic system.

Safety Considerations

When working with hydraulic systems and the 4016422 Hydraulic Motor Return Line, it is important to follow proper safety procedures. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against hydraulic fluid splashes. Additionally, understanding the potential hazards associated with high-pressure systems, such as fluid injection injuries, is crucial. Always ensure the system is depressurized before performing any maintenance or repairs.

Environmental Impact

The environmental impact of the 4016422 Hydraulic Motor Return Line should be considered in terms of both its use and disposal. The component is designed to be durable and long-lasting, which reduces the frequency of replacements and associated waste. When disposing of the line, it is important to follow recycling recommendations for metal components and proper disposal methods for any hydraulic fluid residues to minimize environmental harm.

Cummins Overview

Cummins is a well-established company with a rich history in the commercial truck industry. Known for its innovative products and commitment to quality, Cummins offers a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles. The company’s dedication to advancing technology and improving efficiency is evident in its diverse product offerings, which include engines, powertrains, and various aftermarket parts.

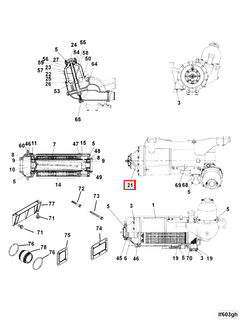

Hydraulic Motor Return Line (Part 4016422) in Cummins Engines

The Hydraulic Motor Return Line, part number 4016422, is a critical component in the hydraulic systems of various Cummins engines. This part is integral to the proper functioning of the hydraulic systems in these engines, ensuring efficient fluid circulation and system performance.

QSK60 Series

The Hydraulic Motor Return Line is compatible with several models within the QSK60 series. Specifically, it fits with:

- QSK60 CM500

- QSK60 CM850 MCRS

- QSK60G

These engines utilize the Hydraulic Motor Return Line to manage the return flow of hydraulic fluid, which is essential for maintaining system pressure and ensuring the hydraulic motors operate smoothly. The part’s design ensures that it can handle the specific demands of these engines, providing a reliable connection point for the hydraulic system.

QSK78 Series

Additionally, the Hydraulic Motor Return Line is also compatible with:

- QSK78 CM500

In the QSK78 series, this part plays a similar role in managing the hydraulic fluid’s return flow. The design and specifications of the Hydraulic Motor Return Line are tailored to meet the unique requirements of the QSK78 CM500 engine, ensuring optimal performance and longevity of the hydraulic system.

Compatibility and Installation

The Hydraulic Motor Return Line is engineered to fit seamlessly into the hydraulic systems of the specified Cummins engines. Its design ensures a secure and leak-free connection, which is crucial for maintaining system integrity and preventing hydraulic fluid loss. Proper installation of this part is essential for the efficient operation of the engine’s hydraulic components.

Role of Part 4016422 Hydraulic Motor Return Line in Engine Systems

The part 4016422 Hydraulic Motor Return Line is an essential component in the efficient operation of various engine systems. It facilitates the return of hydraulic fluid from the hydraulic motor back to the reservoir, ensuring a continuous and smooth operation of the hydraulic system.

Interaction with Lubricating Oil Filter

In systems where the hydraulic fluid also serves as a lubricating medium, the return line plays a significant role in maintaining the cleanliness of the fluid. As the hydraulic fluid returns to the reservoir, it often passes through the lubricating oil filter. This filter removes contaminants and debris that the fluid may have picked up during its cycle through the hydraulic motor and other components. Clean fluid is vital for the longevity and performance of the engine, as contaminants can cause wear and reduce efficiency.

Integration with Lubricating Oil Tube Kit

The lubricating oil tube kit is another component that works in conjunction with the Hydraulic Motor Return Line. This kit typically includes various tubes and connectors that facilitate the movement of lubricating oil throughout the engine system. The return line ensures that the hydraulic fluid, which may also be used as lubricating oil, is efficiently circulated back to the reservoir. From there, it can be re-pressurized and re-distributed to various parts of the engine that require lubrication. This seamless integration helps in maintaining optimal lubrication levels, which is essential for the smooth operation and durability of engine components.

Conclusion

The 4016422 Hydraulic Motor Return Line is integral to the hydraulic and lubrication systems of an engine. It ensures that hydraulic fluid is effectively returned to the reservoir, where it can be filtered and re-circulated, thereby supporting the overall efficiency and reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.