This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

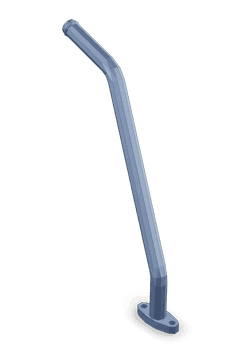

The Turbine Oil Drain Tube (5309254) by Cummins is a component designed to facilitate the efficient drainage of oil from the turbine housing in heavy-duty trucks. This part is integral to the lubrication system, ensuring that oil is effectively managed and maintained within the engine. Its role is significant in preserving the operational integrity and performance of the truck’s engine 1.

Function and Operation

The Turbine Oil Drain Tube operates within the truck’s lubrication system by providing a pathway for oil to drain from the turbine housing. This process is vital for maintaining the proper oil levels and ensuring that the lubrication system functions correctly. By allowing oil to be efficiently drained, the tube helps prevent oil buildup, which can lead to increased wear and reduced efficiency of the engine components 2.

Key Features

The Turbine Oil Drain Tube is constructed with specific design and construction features that enhance its performance. It is typically made from durable materials that can withstand the high temperatures and pressures within the engine environment. The tube’s dimensions are engineered to fit precisely within the engine’s lubrication system, ensuring a secure and effective connection. Additionally, the design may include features such as reinforced edges or specialized coatings to further improve durability and performance 3.

Benefits

The Turbine Oil Drain Tube offers several advantages that contribute to the overall efficiency and reliability of the truck’s engine. By facilitating efficient oil drainage, it helps maintain optimal lubrication levels, which can lead to improved engine performance. Additionally, the tube’s design reduces the frequency of maintenance required, as it helps prevent oil-related issues that can arise from improper drainage. Furthermore, by ensuring consistent lubrication, the tube contributes to the longevity of the engine components, enhancing the overall durability of the truck.

Installation and Maintenance

Proper installation of the Turbine Oil Drain Tube is crucial for ensuring its effective operation. Recommended procedures involve carefully positioning the tube within the engine’s lubrication system and securing it in place using appropriate tools. Regular maintenance checks are advised to ensure the tube remains in good condition. This may include inspecting for signs of wear or damage and ensuring that all connections are secure. Following these guidelines can help maintain the optimal performance and longevity of the component.

Troubleshooting

Common issues associated with the Turbine Oil Drain Tube may include blockages or leaks, which can affect the efficiency of the lubrication system. To diagnose and resolve these problems, it is important to conduct a thorough inspection of the tube and its connections. If a blockage is detected, cleaning or replacing the tube may be necessary. In the case of leaks, ensuring that all connections are tight and secure can often resolve the issue. Regular maintenance and prompt attention to any signs of trouble can help prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a well-established company with a rich history in the automotive industry. Founded in 1919, Cummins has grown to become a leading manufacturer of diesel engines, related technologies, and power generation equipment. The company is known for its commitment to innovation, quality, and customer satisfaction. Cummins’ product offerings span a wide range of applications, from heavy-duty trucks to industrial and marine engines. The reputation of Cummins is built on its dedication to producing reliable and high-performance components, such as the Turbine Oil Drain Tube, which are designed to meet the demanding requirements of modern engines.

Turbine Oil Drain Tube (Part 5309254) Compatibility with Cummins Engines

The Turbine Oil Drain Tube, identified by part number 5309254 and manufactured by Cummins, is a critical component in the maintenance and operation of several Cummins engine models. This part is designed to facilitate the drainage of oil from the turbine section of the engine, ensuring optimal performance and longevity.

ISL G CM2180 Engines

The ISL G CM2180 engines are part of Cummins’ lineup of high-performance, heavy-duty diesel engines. These engines are known for their robust design and efficiency, making them suitable for a variety of applications, including heavy-duty trucks, construction equipment, and industrial machinery. The Turbine Oil Drain Tube (5309254) is specifically engineered to fit seamlessly within the ISL G CM2180 engine architecture, providing a reliable means to manage and remove oil from the turbine area.

Group Compatibility

The Turbine Oil Drain Tube (5309254) is also compatible with other Cummins engine groups that share similar design and operational characteristics with the ISL G CM2180. This includes engines that are part of the same family or series, where the internal components and oil management systems are analogous. Ensuring that the correct part is used is crucial for maintaining the integrity of the engine’s oil system and preventing potential failures or inefficiencies.

By integrating the Turbine Oil Drain Tube (5309254) into the engine’s design, Cummins ensures that oil can be effectively drained and managed, contributing to the overall reliability and performance of the engine. This part is a testament to Cummins’ commitment to providing high-quality, durable components that meet the demands of their diverse engine applications.

Role of Part 5309254 Turbine Oil Drain Tube in Engine Systems

The Turbine Oil Drain Tube, identified by part number 5309254, is an essential component in the maintenance and operation of engine systems, particularly those involving turbochargers. This component facilitates the efficient drainage of turbine oil, which is vital for the sustained performance and longevity of the turbocharger.

In the context of plumbing within engine systems, the Turbine Oil Drain Tube ensures that the oil used to lubricate the turbocharger’s moving parts is effectively managed. It connects to the oil sump or collection point within the turbocharger housing, allowing for the periodic or continuous removal of used oil. This process is important for preventing oil buildup, which can lead to increased temperatures and potential damage to the turbocharger.

When integrated with a turbocharger, the Turbine Oil Drain Tube plays a significant role in the overall lubrication system. Turbochargers operate under extreme conditions, with high rotational speeds and temperatures. The oil that lubricates the turbocharger’s bearings and other moving components must be kept clean and at optimal levels to ensure smooth operation. The drain tube allows for the removal of contaminated oil, which can then be replaced with fresh lubricant, maintaining the efficiency and reliability of the turbocharger.

Additionally, the Turbine Oil Drain Tube contributes to the maintenance routine of the engine system. Regular drainage of turbine oil helps in identifying any contaminants or metal particles that may indicate wear or impending failure within the turbocharger. This proactive approach allows for timely interventions, reducing the risk of unexpected downtime and extending the service life of the turbocharger.

Conclusion

In summary, the Turbine Oil Drain Tube (5309254) is a key component in the effective management of turbine oil within engine systems, particularly those equipped with turbochargers. Its role in facilitating the drainage of used oil ensures that the turbocharger remains well-lubricated, operates efficiently, and is maintained in optimal condition. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the benefits of this Cummins part.

-

Hilgers, Michael and Wilfried Achenbach. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Hu, Haoran, Simon J Baseley and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.