This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Tube, identified by part number 4942281, is a component manufactured by Cummins, a leading name in diesel engine technology. This tube is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Cummins, known for its robust and reliable engine components, ensures that this part meets the demanding requirements of modern diesel engines 1.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Tube, it is important to first grasp the fundamentals of turbochargers. A turbocharger is a device that increases an engine’s efficiency and power output by compressing the air entering the engine. In diesel engines, turbochargers play a pivotal role in enhancing performance and fuel efficiency. The turbocharger operates at high speeds and temperatures, necessitating effective oil lubrication to reduce friction and wear on moving parts. This lubrication is crucial for maintaining the turbocharger’s efficiency and longevity 2.

Purpose of the Turbocharger Oil Drain Tube

The Turbocharger Oil Drain Tube serves a specific function within the turbocharger system. It is responsible for the circulation and drainage of oil, ensuring that the turbocharger remains properly lubricated. The tube allows oil to flow from the engine’s lubrication system into the turbocharger, where it lubricates critical components. After lubrication, the oil is drained back into the engine’s oil sump, completing the circulation cycle. This process is vital for maintaining the turbocharger’s operational integrity and efficiency.

Key Features

The design and construction of the Turbocharger Oil Drain Tube are tailored to meet the rigorous demands of heavy-duty applications. Constructed from durable materials, the tube is resistant to the high temperatures and pressures encountered in turbocharger systems. It features secure connection types that ensure a reliable seal, preventing oil leaks. Unique design elements may include reinforced sections to withstand mechanical stresses and precise engineering to ensure optimal oil flow.

Benefits

The incorporation of the Turbocharger Oil Drain Tube into a turbocharger system offers several advantages. By ensuring consistent and effective oil lubrication, the tube contributes to the longevity of the turbocharger. This, in turn, enhances the overall performance of the engine, allowing it to operate more efficiently. Additionally, the tube’s design reduces the frequency of maintenance required, offering convenience and cost savings over the engine’s lifespan.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Tube is crucial for its effective operation. Installation procedures should follow manufacturer guidelines to ensure secure and correct fitting. Specific requirements may include the use of compatible fittings and adherence to torque specifications. The tube is designed to be compatible with a range of Cummins engine models and turbocharger systems, ensuring versatility across different applications.

Troubleshooting and Maintenance

Common issues with Turbocharger Oil Drain Tubes may include oil leaks or blockages, which can affect turbocharger performance. Diagnostic procedures should involve a thorough inspection of the tube and connections for signs of wear or damage. Regular maintenance, such as checking for proper oil flow and ensuring connections are secure, can help prevent issues and ensure optimal performance. Following manufacturer recommendations for maintenance intervals is advised.

Cummins Overview

Cummins Inc. has a long-standing reputation in the diesel engine and component manufacturing industry. Founded with a commitment to quality and innovation, Cummins has consistently delivered reliable and high-performance engine components. The company’s dedication to research and development ensures that its products, including the Turbocharger Oil Drain Tube, meet the evolving needs of the heavy-duty truck industry. Cummins’ focus on customer satisfaction and technological advancement underscores its position as a leader in the field 3.

Turbocharger Oil Drain Tube (Part 4942281) in Cummins Engines

The Turbocharger Oil Drain Tube, identified by part number 4942281 and manufactured by Cummins, is a critical component in the maintenance and operation of several Cummins engine models. This part is integral to the turbocharger system, ensuring that oil is properly drained from the turbocharger to prevent oil accumulation and potential damage.

ISL G CM2180 Engines

In the ISL G CM2180 engines, the Turbocharger Oil Drain Tube is designed to fit seamlessly within the turbocharger assembly. This part ensures that any excess oil is efficiently drained from the turbocharger, maintaining optimal lubrication levels and preventing oil from entering the turbine and compressor sections. The precise fit and design of the drain tube are crucial for maintaining the performance and longevity of the turbocharger.

Group Compatibility

The Turbocharger Oil Drain Tube (4942281) is compatible with a range of Cummins engines, including but not limited to, the ISL G CM2180. This compatibility is due to the standardized design and engineering principles that Cummins employs across its engine lineup. The drain tube is engineered to meet the specific requirements of each engine model, ensuring a reliable and effective oil drainage system.

By ensuring that the turbocharger oil drain tube is correctly installed and functioning, engine operators can maintain the integrity of the turbocharger system, leading to improved engine performance and reduced maintenance costs.

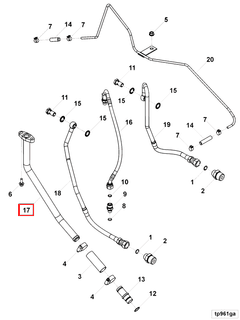

Role of Part 4942281 Turbocharger Oil Drain Tube in Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Tube (Part 4942281) is integral to the system’s functionality and maintenance. This component is designed to facilitate the drainage of oil from the turbocharger, ensuring that the oil does not accumulate within the system, which could lead to inefficiencies and potential damage.

The Turbocharger Oil Drain Tube is connected to the turbocharger housing, where it interfaces with the oil supply and return lines. Its primary function is to provide a clear path for the oil to exit the turbocharger after lubrication. This is essential for maintaining the turbocharger’s performance and longevity.

When the engine is operational, oil is circulated through the turbocharger to lubricate the rotating components, such as the turbine and compressor wheels. After performing its lubricating function, the oil needs to be drained back into the engine’s oil sump to be recirculated. The Turbocharger Oil Drain Tube ensures this process is seamless by offering a dedicated route for the oil to flow out of the turbocharger.

Additionally, the Turbocharger Oil Drain Tube plays a role in the overall turbocharger plumbing system by connecting to other components such as the oil feed line, oil return line, and the oil drain back to the engine sump. This integration ensures that the oil management within the turbocharger system is efficient and reliable.

In summary, the Turbocharger Oil Drain Tube (Part 4942281) is a key element in turbocharger plumbing, responsible for the effective drainage of oil, thereby supporting the turbocharger’s operational efficiency and durability.

Conclusion

The Turbocharger Oil Drain Tube (Part 4942281) is a vital component in the maintenance and operation of Cummins engines, particularly in the context of turbocharger systems. Its role in facilitating the efficient drainage of oil ensures that the turbocharger remains properly lubricated, which is crucial for maintaining engine performance and longevity. The design and construction of this Cummins part are tailored to withstand the high temperatures and pressures of heavy-duty applications, ensuring reliable operation and reduced maintenance requirements. Proper installation and regular maintenance of the Turbocharger Oil Drain Tube are essential for optimal turbocharger performance and overall engine efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.