This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2871752 Inlet Catalyst Module is a component designed for use in heavy-duty trucks. It is part of the exhaust system and plays a role in reducing emissions and enhancing engine performance. This module is engineered to work in conjunction with other emission control technologies to ensure compliance with environmental regulations 1.

Function and Operation

The Inlet Catalyst Module operates by processing exhaust gases before they enter the diesel particulate filter (DPF). It contains a catalyst that facilitates the conversion of harmful pollutants into less harmful substances. This process is integral to the overall emission control system, helping to minimize the environmental impact of heavy-duty trucks 2.

Purpose of the Inlet Catalyst Module

The primary functions of the Inlet Catalyst Module include reducing emissions and improving engine performance. By converting pollutants such as nitrogen oxides (NOx) and hydrocarbons (HC) into nitrogen, water, and carbon dioxide, it helps in meeting stringent emission standards. Additionally, it contributes to better engine efficiency by ensuring that the exhaust system operates optimally 3.

Key Features

This Cummins part is characterized by several key features. Its design incorporates advanced catalyst technology, which enhances its effectiveness in reducing emissions. The module is constructed using durable materials that can withstand the high temperatures and pressures of the exhaust system. Technological advancements in its design ensure it provides reliable performance over an extended period.

Benefits

Using the Inlet Catalyst Module offers several advantages. It contributes to improved fuel efficiency by ensuring the engine operates more cleanly and efficiently. Reduced emissions are a direct result of its effective pollutant conversion process. Additionally, the module enhances engine durability by maintaining optimal exhaust system performance, which can lead to longer engine life.

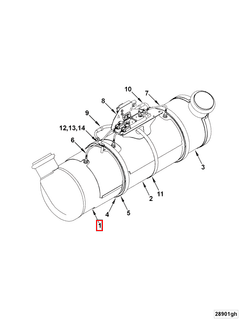

Installation Process

Installing the Inlet Catalyst Module involves several steps. First, the existing module, if present, must be removed. This may require disconnecting various components of the exhaust system. The new module is then positioned and secured in place using the appropriate fasteners. It is important to follow manufacturer guidelines to ensure proper installation and to use the necessary tools to avoid damage to the component or surrounding parts.

Common Issues and Troubleshooting

Common issues with the Inlet Catalyst Module may include catalyst deactivation, physical damage, or blockages. Symptoms of these problems can include increased emissions, reduced engine performance, or warning lights on the dashboard. Troubleshooting involves inspecting the module for physical damage, checking for blockages, and ensuring all connections are secure. If the catalyst is deactivated, replacement may be necessary.

Maintenance Tips

Regular maintenance of the Inlet Catalyst Module is important to ensure its longevity and efficiency. This includes periodic inspections for physical damage or blockages, ensuring all connections are tight, and monitoring the overall performance of the exhaust system. Following the manufacturer’s maintenance schedule can help prevent issues and ensure the module continues to operate effectively.

Regulatory Compliance

The Inlet Catalyst Module plays a role in helping trucks meet environmental regulations and emission standards. By reducing harmful emissions, it ensures that heavy-duty trucks comply with local and federal environmental laws. This is particularly important in regions with strict emission control requirements, where non-compliance can result in fines or other penalties.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, the company has a long history of innovation in the automotive industry, particularly in the development of emission control technologies. Cummins is committed to providing solutions that enhance engine performance while reducing environmental impact.

Role of Part 2871752 Inlet Catalyst Module in Aftertreatment Device

The Inlet Catalyst Module (part 2871752) is an integral component within the aftertreatment device of modern engine systems. Its primary function is to facilitate the initial stages of exhaust gas treatment before the gases enter further downstream components.

When exhaust gases exit the engine, they pass through the Inlet Catalyst Module. This module is designed to begin the reduction of harmful emissions such as nitrogen oxides (NOx) and particulate matter (PM). The catalyst within the module activates at relatively lower temperatures compared to other catalysts in the aftertreatment system, ensuring that emission reduction starts as soon as possible after the engine is operational.

The treated exhaust then flows from the Inlet Catalyst Module to the Diesel Oxidation Catalyst (DOC), where further oxidation of carbon monoxide (CO) and hydrocarbons (HC) occurs. Subsequently, the exhaust moves through the Diesel Particulate Filter (DPF), where particulate matter is trapped and periodically burned off during regeneration cycles.

In certain engine systems, the exhaust may also pass through a Selective Catalytic Reduction (SCR) system, where urea is injected to convert NOx into harmless nitrogen (N2) and water (H2O). The Inlet Catalyst Module ensures that the exhaust entering these subsequent components is already partially treated, enhancing the overall efficiency of the aftertreatment process.

Conclusion

In summary, the Inlet Catalyst Module (part 2871752) plays a significant role in the initial treatment of exhaust gases, setting the stage for the effective operation of downstream aftertreatment components. Its advanced design and durable construction ensure reliable performance and contribute to the overall efficiency of the emission control system in heavy-duty trucks.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.