This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

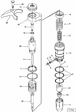

The Cummins 3071500 Injector is a critical component in commercial trucks, specifically designed for Cummins diesel engines. It ensures precise and controlled fuel delivery into the combustion chamber, enhancing engine performance, fuel efficiency, and reliability. This part is essential for the maintenance and operation of commercial vehicles.

Basic Concepts of Fuel Injectors

Fuel injectors in diesel engines spray fuel into the combustion chamber at high pressure, ensuring proper atomization for better air mixing and complete combustion. This process is fundamental to diesel engine operation, affecting power output, fuel consumption, and emissions 1.

Purpose of the Cummins 3071500 Injector

The Cummins 3071500 Injector is engineered for the fuel delivery system of Cummins engines. It injects fuel at precise moments and quantities determined by the engine’s electronic control unit (ECU), contributing to optimal fuel delivery and engine performance under various conditions 2.

Key Features

This Cummins part features a robust design and high-quality materials for durability and performance. It includes precision engineering for accurate fuel delivery and resistance to wear and corrosion, ensuring reliability and longevity in commercial truck applications 3.

Benefits of Using the Cummins 3071500 Injector

Using this injector offers improved fuel efficiency, enhanced engine performance through consistent fuel delivery, and reliability in demanding commercial truck operations. It is designed to withstand the rigors of such environments.

Installation and Integration

Proper installation of the 3071500 Injector is crucial for effective operation. It involves securing the injector in the engine’s fuel delivery system, ensuring correct alignment and tightening to manufacturer specifications. Tools like torque wrenches and specialized fittings are required for a secure and leak-free connection.

Maintenance and Troubleshooting

Regular maintenance of the 3071500 Injector is vital for reliable operation. This includes periodic inspection for wear or damage, cleaning to remove deposits, and troubleshooting issues like leaks or misfires. Adhering to the manufacturer’s maintenance schedule helps prevent failures and extends the injector’s service life.

Performance Optimization

Optimizing the performance of the 3071500 Injector requires proper tuning and calibration of the engine’s ECU. This ensures the injector operates within its designed parameters for efficient fuel delivery. Regular ECU software updates can also improve performance and fuel efficiency.

Safety Considerations

When working with the 3071500 Injector, safety precautions are important. This includes careful handling to avoid damage, using appropriate personal protective equipment (PPE) during maintenance or repairs, and storing the injector in a safe, dry location when not in use. These guidelines ensure personnel safety and injector integrity.

Environmental Impact

The use of the 3071500 Injector contributes to reduced emissions and improved fuel efficiency. By ensuring precise fuel delivery, it benefits operators through cost savings and reduces the environmental footprint of commercial truck operations by minimizing fuel consumption and emissions.

Cummins Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With over a century of history, Cummins is renowned for quality, reliability, and innovation in the automotive and heavy-duty truck industries. Its product range includes engines and components for demanding commercial and industrial applications.

Role of Part 3071500 Injector in Engine Systems

The 3071500 injector enhances engine system performance by ensuring precise fuel delivery. It operates with key components to optimize engine efficiency and power output.

Fuel Rail Integration

The injector is mounted on the fuel rail, which distributes pressurized fuel to each cylinder. It atomizes fuel into a fine mist for better combustion and improved engine performance. The fuel rail’s consistent pressure allows the injector to deliver fuel accurately, contributing to smoother engine operation.

Engine Control Unit (ECU) Communication

The injector communicates with the ECU, which monitors engine parameters like throttle position, engine speed, and air-fuel ratio. The ECU sends signals to the injector to open and close at specific intervals, ensuring the correct amount of fuel is delivered based on real-time data. This interaction is essential for maintaining optimal performance and fuel efficiency.

Throttle Body and Air Intake System

As air enters the engine through the throttle body and air intake system, the injector releases fuel into the air stream. The precise timing and quantity of fuel injection are vital for achieving the desired air-fuel mixture, impacting combustion efficiency, engine power output, and emissions.

Combustion Chamber Dynamics

The injector’s performance is evident in the combustion chamber. The atomized fuel ensures a more complete burn, translating to better engine performance and reduced emissions. The injector’s ability to deliver fuel consistently and accurately under varying engine loads and speeds is key to maintaining high performance.

Exhaust System Efficiency

The efficiency of the injector influences the exhaust system. A well-atomized fuel mixture leads to more complete combustion, resulting in fewer unburned hydrocarbons and other pollutants entering the exhaust stream. This improves engine performance and ensures the exhaust system operates more efficiently, reducing the workload on catalytic converters and other emission control devices.

Performance Parts Synergy

When integrated with other performance parts like high-flow air filters, performance exhaust systems, and upgraded ECUs, the 3071500 injector significantly enhances engine performance. These components work in harmony to improve airflow, fuel delivery, and combustion efficiency, resulting in overall engine performance improvement.

Conclusion

The 3071500 injector is a vital component in the engine system, working seamlessly with other parts to ensure optimal performance, efficiency, and reliability. Its precise fuel delivery, integration with the fuel rail and ECU, and role in combustion and exhaust efficiency make it essential for the operation of Cummins diesel engines in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.