3803518

Intake Valve

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3803518 Intake Valve is a component designed for use in commercial trucks, specifically within Cummins engines. Its purpose is to regulate the flow of air into the engine’s combustion chamber. This valve’s operation is significant for maintaining the efficiency and performance of the truck’s engine, ensuring that the air-fuel mixture is optimized for combustion 1.

Basic Concepts of an Intake Valve

An intake valve is a component found in internal combustion engines. Its primary function is to allow air, and often a mixture of air and fuel, to enter the engine’s cylinders. This process is vital for the engine’s operation, as it enables the combustion process that drives the engine’s pistons. The efficiency of the intake valve directly influences the engine’s performance, fuel efficiency, and emissions 2.

Role of the 3803518 Intake Valve in Truck Operation

The Cummins 3803518 Intake Valve plays a specific role in the operation of a truck by ensuring a precise and timely flow of air into the engine’s cylinders. This valve’s design and functionality contribute to the engine’s efficiency and performance by allowing for optimal air intake, which is crucial for the combustion process. Proper operation of this valve helps in maintaining the engine’s power output and fuel efficiency 3.

Key Features of the 3803518 Intake Valve

The Cummins 3803518 Intake Valve is characterized by several key features that enhance its functionality. These include its material composition, which is designed to withstand the high temperatures and pressures within the engine, and its precise design, which ensures efficient air flow. Additionally, any unique attributes of this valve, such as specific coatings or treatments, contribute to its durability and performance.

Benefits of Using the 3803518 Intake Valve

Utilizing the Cummins 3803518 Intake Valve in a truck’s engine offers several benefits. These include improved engine performance due to optimized air intake, enhanced durability thanks to its robust construction, and increased reliability, ensuring consistent operation over time. These factors contribute to the overall efficiency and longevity of the engine.

Troubleshooting and Maintenance Suggestions

Common issues with the Cummins 3803518 Intake Valve may include wear and tear, leading to leaks or inefficient air flow. Troubleshooting steps may involve inspecting the valve for signs of damage or malfunction and ensuring it is properly seated within the engine. Regular maintenance practices, such as cleaning and checking for proper operation, can help ensure the valve’s optimal performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, demonstrating a commitment to excellence and customer satisfaction.

Role of Part 3803518 Intake Valve in Engine Systems

The 3803518 Intake Valve is an essential component within the engine system, specifically interacting with the Cylinder Head Rebuild Kit and Cylinder Head Repair Kit.

When integrated with the Cylinder Head Rebuild Kit, the Intake Valve works in conjunction with other components such as the valve springs, valve seats, and valve guides. This kit is designed to restore the cylinder head to its original performance specifications. The Intake Valve, as part of this rebuild process, ensures that air and fuel mixture is efficiently drawn into the combustion chamber during the intake stroke. Proper seating and alignment of the Intake Valve within the cylinder head are vital for optimal engine performance and longevity.

In the context of the Cylinder Head Repair Kit, the Intake Valve plays a significant role in addressing wear and damage within the cylinder head. This kit typically includes components like valve seals, shims, and retainers, all of which work together to maintain the integrity of the valve train. The Intake Valve, when repaired or replaced using this kit, contributes to the overall efficiency of the engine by ensuring a consistent and controlled intake of the air-fuel mixture, which is essential for combustion efficiency and power output.

Both kits highlight the importance of the Intake Valve in maintaining the engine’s performance, demonstrating its integral role in the engine’s operation and the necessity for precise installation and maintenance.

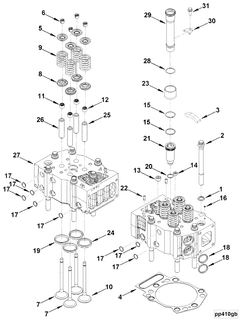

Components of Cummins Intake Valve Kit 3803518

Valve Collet (205091)

The valve collet is a critical component within the Cummins intake valve kit 3803518. Its primary role is to securely hold the intake valve in place within the valve guide. The collet ensures that the valve operates smoothly and maintains proper alignment during the engine’s operation. It is designed to withstand high temperatures and pressures, contributing to the overall durability and efficiency of the intake valve system.

Intake Valve (3052820)

The intake valve is the central component of the Cummins intake valve kit 3803518. This valve is responsible for controlling the airflow into the engine’s combustion chamber. It opens and closes in synchronization with the engine’s camshaft, allowing air and fuel to enter the chamber at the precise moment for optimal combustion. The intake valve is engineered to endure the extreme conditions within the engine, ensuring reliable performance and longevity.

Conclusion

The Cummins 3803518 Intake Valve is a vital component in the operation of commercial truck engines, playing a crucial role in regulating air intake for optimal combustion. Its design and features contribute to engine efficiency, performance, and longevity. Regular maintenance and proper installation are essential for ensuring the valve’s optimal performance and the overall reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.