3937214

Piston Cooling Nozzle

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Piston Cooling Nozzle 3937214, manufactured by Cummins, is a critical component in the cooling systems of heavy-duty truck engines. This part is designed to manage the temperature of the piston, ensuring optimal engine performance and longevity.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are essential in the cooling systems of internal combustion engines. They work by directing a stream of lubricating oil onto the underside of the piston to dissipate heat, which is vital for maintaining the structural integrity of the piston and enhancing engine efficiency 1.

Role of the Piston Cooling Nozzle 3937214 in Truck Operation

The Piston Cooling Nozzle 3937214 ensures that the piston remains within optimal temperature ranges by spraying oil onto its underside. This process is essential for maintaining engine reliability and performance, preventing overheating which can lead to engine damage 2.

Key Features

This Cummins part is crafted from high-quality materials to withstand harsh engine conditions. Its design ensures a consistent and directed oil spray, critical for effective cooling. The robust construction allows it to endure high pressures and temperatures typical in heavy-duty truck engines.

Benefits

Utilizing the Piston Cooling Nozzle 3937214 contributes to improved engine efficiency by maintaining optimal piston temperatures, reducing the risk of piston damage. It also enhances the overall longevity of the engine by ensuring safe temperature limits are maintained 3.

Troubleshooting and Maintenance

Regular inspection and maintenance of the Piston Cooling Nozzle 3937214 are recommended to ensure its longevity and effectiveness. Common issues include clogging or wear affecting the spray pattern. Maintenance practices should include cleaning the nozzle and inspecting it for any signs of wear or damage.

About Cummins

Cummins Inc. is a global power leader known for its innovation, quality, and customer satisfaction in the automotive and heavy-duty truck industry. The company’s product range includes engines, filtration systems, and other components renowned for their reliability and performance.

Compatibility with Cummins Engines

The Piston Cooling Nozzle 3937214 is compatible with a variety of Cummins engines, including the 4B3.9, 6B5.9, B3.9 G, B4.5, B5.9, B5.9 CM2670 B166C, B5.9 G, B5.9 GAS PLUS CM556, B6.7S, G5.9, G5.9 CM558, ISB3.9 CM2220 B107, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB5.9 CM2880 B140, ISB5.9 CM2880 B149, ISB5.9G CM2180, QSB3.9 30 CM550, QSB3.9 CM2880 B138, QSB5.9 30 CM550, QSB5.9 44 CM550, QSB5.9 CM2880 B115, and QSB5.9 CM2880 B139. These engines rely on the precise functionality of the nozzle to maintain optimal operating temperatures.

Integration with Key Engine Components

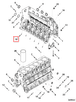

The Piston Cooling Nozzle 3937214 is strategically positioned within the cylinder block, aligned with the piston’s travel path. This setup allows for consistent and precise cooling as the piston moves through its stroke. It works in conjunction with the piston’s oil jet to provide a dual-cooling effect, particularly important in high-performance engines.

Conclusion

The integration of the Piston Cooling Nozzle 3937214 into various engine systems highlights its importance in maintaining optimal engine temperatures and ensuring long-term reliability. Proper installation and alignment within the cylinder block, alongside compatible gasket sets and overhaul kits, are essential for maximizing its effectiveness in thermal management.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.