The Piston Cooling Nozzle 3919002, manufactured by Cummins, is a component designed to enhance the operation of heavy-duty trucks. Cummins, a well-established name in the automotive industry, particularly in the heavy-duty truck sector, produces this nozzle to contribute to the efficient and reliable performance of truck engines 1.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are integral components within an engine’s cooling system. Their primary function is to direct a stream of coolant onto the underside of the piston, thereby managing the temperature and reducing thermal stress 2. This cooling mechanism is vital for maintaining engine performance and extending the longevity of engine components. By effectively managing heat, piston cooling nozzles help prevent overheating, which can lead to engine damage and reduced efficiency.

Purpose of the 3919002 Piston Cooling Nozzle

The 3919002 Piston Cooling Nozzle is specifically designed to aid in the thermal management of truck engines. It plays a role in the engine’s cooling system by spraying coolant onto the piston’s underside, which helps in dissipating heat generated during combustion. This process not only enhances engine efficiency but also contributes to the overall durability of the engine by reducing the risk of thermal damage to the piston 3.

Key Features

The 3919002 Piston Cooling Nozzle is constructed with precision to ensure optimal performance. It is made from high-quality materials that are resistant to corrosion and wear, ensuring longevity and reliability. The nozzle pattern is designed to provide an even distribution of coolant, maximizing cooling efficiency. Additionally, the nozzle’s unique attributes, such as its robust construction and precise engineering, enhance its performance and reliability in demanding engine environments.

Benefits

The advantages of using the 3919002 Piston Cooling Nozzle include improved engine durability, enhanced fuel efficiency, and a reduced risk of piston damage. By effectively managing engine temperatures, this nozzle contributes to the overall reliability and performance of the engine. Furthermore, its design helps in maintaining optimal engine operating conditions, which can lead to longer engine life and reduced maintenance costs.

Installation and Compatibility

Proper installation of the 3919002 Piston Cooling Nozzle is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure compatibility with specific engine models. Installation procedures may vary depending on the engine design, and it is advisable to consult the manufacturer’s instructions for detailed guidance. Ensuring correct installation will help in achieving the desired cooling performance and engine efficiency.

Maintenance and Troubleshooting

Regular maintenance of the 3919002 Piston Cooling Nozzle is important to ensure its continued efficient operation. This includes routine inspections for signs of wear or damage, cleaning to remove any deposits that may obstruct the coolant flow, and troubleshooting any issues that arise. Proper maintenance helps in preventing potential problems and ensures the nozzle continues to perform its cooling function effectively.

Performance Impact

The 3919002 Piston Cooling Nozzle has a noticeable impact on engine performance. By effectively managing engine temperatures, it contributes to improved efficiency, power output, and reliability. Engines equipped with this nozzle are likely to experience reduced thermal stress, leading to enhanced durability and performance under various operating conditions.

Cummins Corporation

Cummins Corporation, the manufacturer of the 3919002 Piston Cooling Nozzle, has a long-standing reputation in the automotive industry. Known for its commitment to quality and innovation, Cummins offers a wide range of products designed for heavy-duty applications. The company’s expertise in engine technology and components is reflected in the design and performance of the 3919002 Piston Cooling Nozzle, making it a reliable choice for enhancing engine cooling in heavy-duty trucks.

Piston Cooling Nozzle Compatibility with Cummins Engines

The Piston Cooling Nozzle, part number 3919002, is a critical component designed to enhance the cooling efficiency of the pistons in various Cummins engines. This part is engineered to fit seamlessly with several models, ensuring optimal performance and longevity of the engine.

Compatible Engines

- 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ lineup of medium-duty diesel engines. The 3919002 Piston Cooling Nozzle is specifically designed to fit these engines, providing efficient cooling to the pistons and thereby reducing the risk of overheating and wear.

- B5.9 G Engine

The B5.9 G engine, another variant in Cummins’ range, also benefits from the 3919002 Piston Cooling Nozzle. This nozzle ensures that the pistons remain at an optimal temperature, enhancing the engine’s overall efficiency and durability.

- ISB CM550 and QSB5.9 44 CM550 Engines

The ISB CM550 and QSB5.9 44 CM550 engines are high-performance models in Cummins’ portfolio. The 3919002 Piston Cooling Nozzle is engineered to fit these engines, providing precise and effective cooling to the pistons. This ensures that the engines can operate at peak performance levels without the risk of thermal damage.

By integrating the 3919002 Piston Cooling Nozzle into these engines, Cummins ensures that the pistons are kept at an optimal temperature, thereby enhancing the engine’s efficiency, reliability, and lifespan. This compatibility across various engine models underscores the versatility and effectiveness of this Cummins part in maintaining engine health.

Integration of Part 3919002 Piston Cooling Nozzle with Engine Systems

The part 3919002 Piston Cooling Nozzle is a specialized component designed to enhance the performance and longevity of various engine systems by ensuring optimal cooling of the pistons. Its integration with different engine components is essential for maintaining efficient operation and preventing overheating.

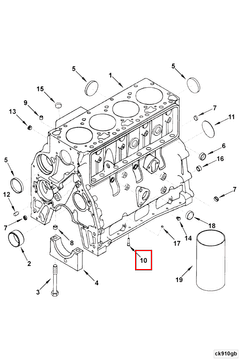

Compatibility with Block and Short Block Variants

When installed in conjunction with a Block Hardware Kit, the Piston Cooling Nozzle ensures that the cooling system is adequately supported by the necessary hardware, promoting a seamless fit and function. For Short 6BT Blocks, Short E2 Incent Blocks, Short E3 Incent Blocks, and Short Euro1 Blocks, the nozzle plays a significant role in dissipating heat from the pistons, which is vital for the durability of these compact engine designs.

Role in Cylinder Block Assemblies

In a Cylinder Block or a Cylinder Block Hardware Kit, the Piston Cooling Nozzle is integrated to provide direct cooling to the piston crowns. This is particularly important in high-stress areas where heat buildup can lead to deformation or failure. The Cylinder Block Kit and Cylinder Short Block benefit from the nozzle’s precise cooling, which helps in maintaining the integrity of the piston and cylinder interface.

Essential for Engine Block and Overhaul Kits

The Engine Block relies on the efficient operation of the Piston Cooling Nozzle to prevent thermal damage. When paired with a Lower Engine Gasket Kit or Lower Engine Gasket Set, the nozzle ensures that coolant is effectively directed to critical areas, reducing the risk of gasket failure due to excessive heat. In an Overhaul Kit or Rebuild Kit, the inclusion of the nozzle is standard practice to restore the engine to optimal working condition, ensuring that all components, especially the pistons, are adequately cooled.

Specific Applications in Short Block Configurations

For configurations such as the Short 6B Block, Short Block, Short Block Kit, Short E1 180 Block, and Short E2 215/235 Block, the Piston Cooling Nozzle is integral to the design. These blocks are often used in performance applications where heat management is paramount. The nozzle’s role in these setups is to provide consistent and reliable cooling, which is essential for the high-performance demands placed on these engines.

Conclusion

In summary, the part 3919002 Piston Cooling Nozzle is a vital component across various engine block and short block configurations. Its proper integration ensures that pistons remain within safe operating temperatures, contributing to the overall efficiency and reliability of the engine system.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.