This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4387657 Doser Fluid Supply Module is a critical component in the Selective Catalytic Reduction (SCR) system of various Cummins diesel engines. This module is essential for the precise delivery of Diesel Exhaust Fluid (DEF) into the exhaust stream, facilitating the reduction of nitrogen oxides (NOx) emissions.

Basic Concepts

The Doser Fluid Supply Module operates within the SCR system, which converts NOx in the exhaust into nitrogen and water vapor using DEF. DEF, a urea-water solution, is injected into the exhaust stream where it decomposes into ammonia. This ammonia then reacts with NOx over a catalyst to form harmless nitrogen and water 1.

Operation of the Doser Fluid Supply Module

The module’s operation involves the precise injection of DEF into the exhaust stream upstream of the SCR catalyst. This injection is controlled by the dosing control unit, which monitors various parameters such as exhaust temperature, flow rate, and NOx levels. The module ensures that the DEF is atomized and evenly distributed for optimal reaction with the exhaust gases 2.

Purpose and Role in Truck Operation

In truck operations, the Doser Fluid Supply Module plays a significant role in emission control. It helps trucks meet stringent environmental regulations by reducing NOx emissions. This ensures compliance with regulatory standards and contributes to improved air quality 3.

Key Features

This Cummins part is characterized by its robust design and construction, utilizing materials that withstand the harsh conditions of the exhaust system. It incorporates advanced technology for precise DEF dosing, ensuring efficient emission reduction. The module is also designed for easy integration into the truck’s emission control system.

Benefits

The advantages of the Doser Fluid Supply Module include enhanced emission control, leading to better environmental compliance. It also contributes to improved engine performance by ensuring the SCR system operates efficiently. Additionally, by reducing emissions, it can lead to potential cost savings for fleet operators through lower fines and better fuel efficiency.

Troubleshooting and Maintenance

Common issues with the Doser Fluid Supply Module may include clogging or malfunction of the injectors. Regular maintenance, such as cleaning and inspection of the injectors, is recommended to ensure optimal performance. Diagnostic procedures should be followed to identify and address any issues promptly.

Integration with Other Systems

The Doser Fluid Supply Module interacts with various components of the truck’s emission control system. It works in conjunction with the DEF tank, dosing control unit, and SCR catalyst to ensure effective emission reduction. Proper integration and communication between these components are crucial for the system’s overall performance.

Regulatory Compliance

The module plays a role in helping trucks meet emissions standards set by regulatory bodies such as the Environmental Protection Agency (EPA) and the European Union (EU). By reducing NOx emissions, it ensures that trucks comply with these regulations, avoiding potential penalties and contributing to a cleaner environment.

Environmental Impact

The use of the Doser Fluid Supply Module results in significant environmental benefits. By reducing NOx emissions, it contributes to improved air quality and helps mitigate the effects of air pollution. This is particularly important in urban areas where diesel trucks are a common source of NOx emissions.

Compatibility with Cummins Engines

The Doser Fluid Supply Module (part number 4387657) is compatible with various Cummins diesel engines, ensuring optimal performance and compliance with emissions regulations.

ISB Series Engines

- ISB (Chrysler)

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISC and ISF Series Engines

- ISC8.3 CM2250

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 AN

ISL and ISX Series Engines

- ISL9 CM2250

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2350 X101

QSB and QSL Series Engines

- QSB6.7 CM2350 B105

- QSL9 CM2350 L102

X15 Series Engine

- X15 CM2350 X116B

Role in Engine Systems

The Doser Fluid Supply Module is integral to the operation of the aftertreatment system in modern engines. This module is responsible for the precise delivery of diesel exhaust fluid (DEF) into the exhaust stream, which is a key process in the reduction of nitrogen oxides (NOx) emissions.

Integration with Aftertreatment Device

In conjunction with the aftertreatment device, the Doser Fluid Supply Module ensures that DEF is injected at optimal intervals and quantities. This injection is timed to coincide with the exhaust gas temperature and flow conditions, enhancing the efficiency of the Selective Catalytic Reduction (SCR) process.

Function within the Aftertreatment System

The aftertreatment system as a whole benefits from the Doser Fluid Supply Module’s role in maintaining the correct DEF-to-exhaust ratio. This system includes various sensors and control units that monitor exhaust conditions and adjust the dosing strategy in real-time.

Interaction with Catalytic Converter

The Doser Fluid Supply Module also plays a supporting role in the performance of the catalytic converter. By ensuring that the SCR process is effective, the module helps to reduce the load on the catalytic converter, allowing it to focus on oxidizing other harmful emissions such as carbon monoxide and hydrocarbons.

Conclusion

The Cummins 4387657 Doser Fluid Supply Module is a vital component that enhances the functionality of the aftertreatment device, aftertreatment system, and catalytic converter by providing the necessary DEF dosing for effective emission control. Its role in ensuring compliance with emissions regulations and contributing to environmental sustainability underscores its importance in modern diesel engine technology.

SPECIFICATIONS

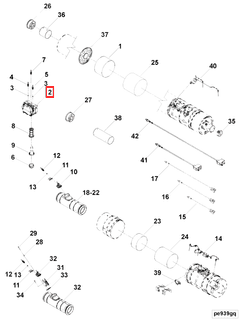

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.