4984929

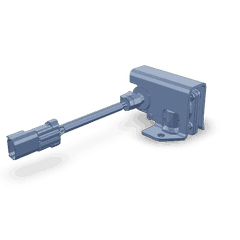

Differential Pressure Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4984929 Differential Pressure Sensor is designed to monitor and measure the pressure differential between two points in a system. In commercial trucks, this sensor ensures the efficient operation of various systems by providing accurate pressure readings to the truck’s electronic control unit (ECU) 2.

Basic Concepts of Differential Pressure Sensors

A differential pressure sensor measures the difference in pressure between two points using a diaphragm that flexes in response to pressure differences, converting mechanical motion into an electrical signal. This signal is processed by the vehicle’s ECU to make adjustments or provide diagnostic information. These sensors are used in emissions control systems, fuel systems, and brake systems to ensure optimal performance and efficiency 3.

Role of the 4984929 Differential Pressure Sensor in Truck Operation

The Cummins 4984929 sensor is integrated into the truck’s system to monitor specific pressure differentials critical for the operation of certain components. It provides the ECU with data for fine-tuning system parameters, such as fuel injection timing or emissions control strategies, helping maintain the truck’s performance within desired parameters under varying operating conditions 1.

Key Features of the 4984929 Differential Pressure Sensor

The Cummins 4984929 sensor features robust construction, precise measurement capabilities, and compatibility with Cummins’ diagnostic systems. These design elements enhance its functionality and reliability, ensuring accurate data transmission to the ECU and easy integration and troubleshooting 2.

Benefits of Using the 4984929 Differential Pressure Sensor

Incorporating the Cummins 4984929 sensor into a truck’s system offers several advantages, including improved system efficiency through accurate control of system parameters, enhanced diagnostic capabilities for quicker identification of potential issues, and cost savings for fleet operators by preventing system malfunctions and reducing the need for frequent repairs 2.

Installation and Integration

Proper installation of the Cummins 4984929 sensor is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring secure mounting and correct electrical connections. Integration with the truck’s system requires careful attention to wiring and connection points to avoid interference with other components and ensure accurate signal transmission to the ECU 2.

Troubleshooting and Maintenance

Common issues with the Cummins 4984929 sensor may include inaccurate readings or sensor failure. Diagnostic procedures involve checking the sensor’s electrical connections, verifying its mounting, and using diagnostic tools to assess its performance. Regular maintenance, such as cleaning the sensor and its connections, can help ensure its longevity and optimal performance. It is also advisable to follow the manufacturer’s recommendations for periodic checks and replacements as part of the truck’s maintenance schedule 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins is committed to innovation, quality, and sustainability in the automotive and industrial sectors. The company’s extensive product range and focus on technological advancement make it a trusted partner for fleet operators and manufacturers alike 2.

Differential Pressure Sensor 4984929 Compatibility with Cummins Engines

The Differential Pressure Sensor 4984929, manufactured by Cummins, is designed to work seamlessly with several of their engine models. This sensor plays a role in maintaining optimal engine performance by monitoring the pressure differential across various components.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine benefits from the 4984929 Differential Pressure Sensor by ensuring precise monitoring of the exhaust gas recirculation (EGR) system. This sensor helps maintain the correct pressure differential, which is essential for the EGR system to function effectively, thereby optimizing fuel efficiency and reducing emissions 2.

ISL G CM2180

In the ISL G CM2180 engine, the 4984929 Differential Pressure Sensor is integral to the turbocharger system. It ensures that the turbocharger operates within the desired pressure range, enhancing overall engine performance and reliability. This sensor’s accurate readings contribute to the engine’s ability to maintain consistent power output and efficiency 2.

ISX12 G CM2180 EJ

For the ISX12 G CM2180 EJ engine, the 4984929 Differential Pressure Sensor is used to monitor the intake manifold pressure. This is vital for the engine’s performance management system, which relies on precise pressure readings to adjust fuel delivery and ignition timing. The sensor’s role in this engine is critical for achieving high performance and maintaining stringent emission standards 2.

These engines, while differing in their specific applications and configurations, all rely on the 4984929 Differential Pressure Sensor for critical pressure monitoring tasks. This ensures that each engine operates at peak efficiency, with reliable performance and reduced emissions 2.

Role of Part 4984929 Differential Pressure Sensor in Engine Systems

The differential pressure sensor, part 4984929, is integral to the precise operation of several engine components, ensuring optimal performance and efficiency.

Integration with Fuel Control

In the context of fuel control, the differential pressure sensor provides real-time data on pressure variations within the fuel system. This data allows the engine control unit (ECU) to make necessary adjustments to fuel delivery, ensuring that the air-fuel mixture remains within the desired parameters. Consequently, this leads to improved combustion efficiency and reduced emissions 3.

Collaboration with Fuel Control Module

When paired with the fuel control module, the differential pressure sensor enhances the module’s ability to regulate fuel flow. The sensor’s accurate pressure readings enable the module to fine-tune the fuel injection timing and quantity, which is essential for maintaining engine performance under varying load conditions. This synergy between the sensor and the module ensures that the engine operates smoothly and efficiently across a wide range of operating conditions 3.

Contribution to Sensor Kit

As part of a comprehensive sensor kit, the differential pressure sensor complements other sensors by providing specific pressure data that is vital for the overall engine management system. This kit typically includes sensors for temperature, airflow, and other parameters. The differential pressure sensor’s role is to offer detailed pressure insights, which, when combined with data from other sensors, allows the ECU to make well-informed decisions regarding fuel and air management. This holistic approach to engine monitoring and control results in enhanced performance, fuel economy, and reliability 3.

Conclusion

The Cummins 4984929 Differential Pressure Sensor plays a significant role in the efficient operation of commercial truck systems by providing accurate pressure readings to the ECU. Its integration into various engine models ensures optimal performance, reliability, and reduced emissions. Proper installation, maintenance, and troubleshooting are essential for the sensor’s effective operation, contributing to the overall efficiency and cost-effectiveness of fleet operations.

-

Engineering Fundamentals of the Internal Combustion Engine, Willard W. Pulkrabek, Pearson Education, 2014.

↩ -

Automotive Braking Systems, Nicholas Goodnight and Kirk Van Gelder, Jones & Bartlett Learning, 2018.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015.

↩ ↩ ↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Rectangular Ring Seal | 1 | 4076823 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.