This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Mounting Kits

Mounting kits are essential for the assembly and operation of commercial trucks. They ensure that various parts and systems are securely fastened to the vehicle’s frame, minimizing vibrations and preventing mechanical failures. A mounting kit typically includes brackets, bolts, and other hardware necessary to attach a specific component to the truck’s chassis 1.

The Role Of The Cummins 5335096 Mounting Kit

The Cummins 5335096 Mounting Kit is specifically designed for use with Cummins engines in commercial trucks. This kit plays a critical role in the proper installation and operation of the engine by providing the necessary hardware to securely mount the engine to the truck’s frame. Proper mounting is essential for maintaining engine alignment, reducing vibrations, and ensuring the longevity of the engine and other connected systems 2.

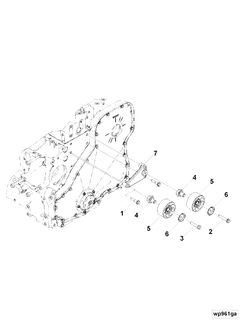

Components Of The Cummins 5335096 Mounting Kit

The Cummins 5335096 Mounting Kit includes several key components:

- Mounting Brackets: These are designed to attach the engine to the truck’s frame. They are typically made from high-strength materials to withstand the forces exerted by the engine.

- Bolts And Nuts: High-quality bolts and nuts are included to ensure a secure connection between the mounting brackets and the engine.

- Gaskets And Seals: These components help to prevent leaks and protect the engine from contaminants.

- Washers And Shims: These are used to ensure proper alignment and to fill any gaps between the mounting brackets and the engine.

Installation Process

Proper installation of this Cummins part is crucial for the performance and safety of the truck. The installation process typically involves the following steps:

- Preparation: Ensure that the truck’s frame and engine are clean and free of debris. Verify that all components of the mounting kit are present and undamaged.

- Alignment: Position the mounting brackets in the correct locations on the truck’s frame. Use alignment tools to ensure that the brackets are level and properly spaced.

- Attachment: Secure the mounting brackets to the truck’s frame using the provided bolts and nuts. Tighten the bolts to the manufacturer’s specified torque settings.

- Engine Mounting: Carefully position the engine onto the mounting brackets. Ensure that all gaskets and seals are in place. Attach the engine to the mounting brackets using the provided hardware.

- Final Checks: Verify that all connections are secure and that the engine is properly aligned. Check for any signs of stress or misalignment.

Troubleshooting And Maintenance

Regular maintenance and troubleshooting are essential for ensuring the longevity and performance of the Cummins 5335096 Mounting Kit. Here are some tips for maintaining and troubleshooting the mounting kit:

- Regular Inspections: Periodically inspect the mounting brackets, bolts, and nuts for signs of wear or damage. Replace any components that show signs of fatigue or corrosion.

- Torque Checks: Regularly check the torque on the bolts to ensure they remain within the manufacturer’s specifications. Loose bolts can lead to engine movement and potential failures.

- Vibration Analysis: Monitor the truck for unusual vibrations that may indicate misalignment or loose connections. Use vibration analysis tools to pinpoint the source of the issue.

- Seal Integrity: Check the gaskets and seals for signs of leaks or degradation. Replace any compromised seals to prevent contamination and leaks.

Components of Cummins Mounting Kit 5335096

Hexagon Flange Head Cap Screws

- 3093826 and 3900635 are both Hexagon Flange Head Cap Screws, which serve as critical fasteners within the mounting kit. These screws are designed with a hexagonal flange at the head, providing a larger surface area for torque application, which enhances the stability and security of the mounted components. Their role is to firmly attach various parts of the mounting system to the engine or other structures, ensuring that the assembly remains intact under operational stresses.

Idler Shaft

- 3935229 is the Idler Shaft, a pivotal component in the mounting kit that supports the rotation of the idler pulley. The idler shaft is responsible for maintaining tension in the belt drive system by adjusting the position of the idler pulley. This ensures consistent belt tension, which is crucial for the efficient transfer of power and smooth operation of the engine’s auxiliary systems.

Idler Pulley

- 3970945 is the Idler Pulley, which works in conjunction with the idler shaft to regulate belt tension. The idler pulley is mounted on the idler shaft and can be adjusted to increase or decrease the tension on the belt. This component is essential for maintaining the proper alignment and tension of the belt, which is vital for the reliable operation of engine accessories such as the alternator, water pump, and air conditioning compressor.

Dust Shield

- 4945913 is the Dust Shield, a protective component that guards the internal mechanisms of the mounting kit from contaminants such as dust, dirt, and debris. The dust shield is typically positioned around moving parts to prevent the ingress of particles that could cause wear, corrosion, or malfunction. Its role is to extend the lifespan of the components by providing a barrier against environmental factors.

Idler Pulley Support

- 5364663 is the Idler Pulley Support, which provides a stable mounting point for the idler pulley and shaft. This support ensures that the idler pulley remains in the correct position and orientation, allowing for precise belt tension adjustment. The idler pulley support is crucial for the overall stability and functionality of the belt drive system within the engine’s mounting configuration.

About Cummins

Cummins is a leading manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. With a history of innovation and quality, Cummins products are known for their reliability and performance. The company’s commitment to research and development ensures that their mounting kits and other components meet the highest standards of engineering and durability 3.

Conclusion

The Cummins 5335096 Mounting Kit is an essential component for the proper installation and operation of Cummins engines in commercial trucks. Understanding the components, installation process, and maintenance requirements of this mounting kit is crucial for ensuring the longevity and performance of the engine and the truck as a whole. By following best practices for installation and maintenance, engineers, mechanics, and fleet operators can ensure that their trucks remain safe, reliable, and efficient 4.

-

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.