5462277

Pressure Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5462277 Pressure Sensor is a component designed for use in commercial trucks. Its purpose is to monitor and report pressure levels within the truck’s systems, providing data that is essential for the engine’s operation and overall performance. This sensor is integrated into the truck’s electronic control system, allowing for precise management of various engine functions.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by electronic systems. In automotive applications, pressure sensors are used to monitor various systems such as the fuel injection, brake system, and engine management. They contribute to ensuring that these systems operate within their optimal parameters, enhancing the vehicle’s efficiency and safety 1.

Role of the 5462277 Pressure Sensor in Truck Operation

The Cummins 5462277 Pressure Sensor is specifically designed to monitor pressure levels in the truck’s fuel system. It provides real-time data to the engine control unit (ECU), which uses this information to adjust fuel delivery and combustion processes. This sensor’s integration into the truck’s systems allows for more accurate fuel management, which can lead to improved engine performance and fuel efficiency. Additionally, it helps in maintaining the engine’s health by ensuring that it operates within safe pressure limits 2.

Key Features

The Cummins 5462277 Pressure Sensor is constructed with high-quality materials to ensure durability and accuracy. Its design includes a robust housing that protects the sensitive internal components from the harsh environments typical in commercial trucking. The sensor utilizes advanced technology to provide precise pressure readings, which are essential for the ECU to make informed adjustments to the engine’s operation.

Benefits

The use of the Cummins 5462277 Pressure Sensor in commercial trucks offers several benefits. It contributes to improved engine performance by enabling more accurate fuel management. This can lead to enhanced fuel efficiency, reducing operational costs. Additionally, by monitoring pressure levels, the sensor plays a role in enhancing safety, as it helps prevent engine damage that could result from operating outside of safe pressure limits. The sensor also contributes to increased efficiency by ensuring that the engine operates at its optimal performance level 3.

Troubleshooting and Maintenance

Common issues with pressure sensors may include inaccurate readings or complete failure. Diagnostic procedures typically involve checking the sensor’s electrical connections and testing its output signal. Regular maintenance, such as cleaning the sensor and its connections, can help ensure optimal performance and longevity. It is also important to follow the manufacturer’s guidelines for replacement intervals to maintain the sensor’s accuracy and reliability.

Compatibility

This Cummins part is designed to fit a variety of Cummins engines, ensuring precise monitoring and control of pressure within the engine’s systems. This sensor is integral for maintaining optimal engine performance and efficiency. Below is a detailed overview of the engines with which this pressure sensor is compatible:

Cummins M Series Engines

- 15N CM2380 M104B

- B5.6 CM2670 B152B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

Cummins ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

Cummins ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

Cummins ISL Series Engines

- ISL CM2150

- ISL G CM2180

- ISL9 CM2250

Cummins ISM Series Engines

- ISM CM876

- ISM11 CM876 SN

Cummins ISX Series Engines

- ISV (Nissan)

- ISX CM871

- ISX12 G CM2180 EJ

- ISX15 CM2250

- ISX15 CM2350 X101

Cummins QSB Series Engines

- QSB3.3 CM2250 EC

- QSB4.5 CM2250 EC

- QSB6.7 CM2250

This pressure sensor is engineered to seamlessly integrate with the specified engines, providing reliable and accurate pressure readings that are crucial for the engine’s operational integrity.

Role in Engine Systems

The 5462277 Pressure Sensor is integral to the efficient operation of various engine systems. It is strategically positioned within the engine’s architecture to monitor and regulate pressure levels, ensuring optimal performance and longevity of the engine components.

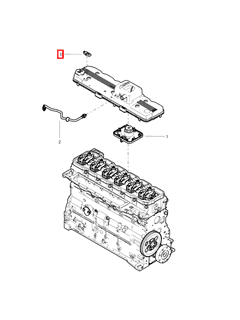

Integration with Crankcase Breather System

In the crankcase breather arrangement, the pressure sensor is connected to the crankcase breather plumbing. This setup allows it to accurately measure the pressure within the crankcase. By doing so, it helps in maintaining the correct pressure levels, which is essential for the proper functioning of the breather system. The sensor’s data is vital for the breather adapter and breather cover to operate effectively, ensuring that the crankcase remains ventilated and free from excessive pressure build-up.

Interaction with Engine Control Module

The pressure sensor communicates directly with the Engine Control Module (ECM). The ECM uses the sensor’s readings to make real-time adjustments to the engine’s operation. This interaction is particularly important in managing the crankcase pressure, as it allows the ECM to implement corrective actions if the pressure deviates from the optimal range. This ensures that the engine operates within safe parameters, reducing the risk of damage to the long block and other critical components.

Role in Valve Cover and Blowby Sensor Kit

When integrated into the valve cover blowby sensor kit, the pressure sensor plays a key role in monitoring the pressure within the valve cover. This is important for detecting any abnormal pressure levels that could indicate issues such as blowby, where combustion gases escape past the piston rings into the crankcase. Early detection of such issues allows for timely maintenance, preventing potential engine damage.

Contribution to Upfit Kit and Long Block Kit

In upfit kits and long block kits, the pressure sensor is a valuable component. It provides essential data that aids in the fine-tuning of the engine’s performance post-installation. The sensor’s ability to provide accurate pressure readings ensures that the engine components, including the molded hose and plumbing systems, are operating under the correct conditions. This is particularly important in ensuring that the long block, which includes the engine block, crankshaft, pistons, and other core components, functions optimally.

Overall Engine System Enhancement

Overall, the 5462277 Pressure Sensor enhances the engine system’s efficiency and reliability. Its integration into various components like the crankcase breather, valve cover, and engine control module ensures that the engine operates under optimal conditions. This not only improves performance but also contributes to the longevity and stability of the engine system.

Conclusion

The Cummins 5462277 Pressure Sensor is a critical component in the operation of commercial truck engines. Its role in monitoring and regulating pressure levels ensures optimal engine performance, enhances fuel efficiency, and contributes to the overall safety and reliability of the vehicle. Regular maintenance and adherence to manufacturer guidelines are essential to ensure the sensor’s longevity and accuracy.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.