Introduction

The Cummins 4954400 Pressure Sensor is a component designed for use in commercial trucks. Manufactured by Cummins, a company renowned for its expertise in engine and component manufacturing, this sensor is integral to the efficient operation of truck systems, providing accurate pressure readings that contribute to overall vehicle performance 1.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the pressure of gases or liquids. They operate by converting pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic systems. In automotive applications, pressure sensors are used in various systems, including engine management, braking, and transmission control, to ensure optimal performance and safety 2.

Role of the 4954400 Pressure Sensor in Truck Operation

The Cummins 4954400 Pressure Sensor plays a specific role in the operation of commercial trucks by monitoring pressure levels within the system. It is integrated into the truck’s systems to provide real-time data that helps in managing engine performance, fuel efficiency, and emissions. The sensor ensures that the truck operates within safe parameters by continuously monitoring and reporting pressure changes 3.

Key Features of the 4954400 Pressure Sensor

The primary features of the Cummins 4954400 Pressure Sensor include its robust design, high-quality materials, and advanced technological specifications. The sensor is engineered to withstand the harsh conditions typical of commercial truck environments. It utilizes precise measurement technology to deliver accurate and reliable data, enhancing the overall performance and durability of the truck’s systems 4.

Benefits of Using the 4954400 Pressure Sensor

Incorporating the Cummins 4954400 Pressure Sensor into truck systems offers several advantages. It contributes to improved efficiency by ensuring that the engine operates under optimal conditions. Additionally, it enhances safety by providing accurate pressure readings that help prevent system failures. Maintenance is also simplified, as the sensor’s reliable performance reduces the need for frequent checks and replacements .

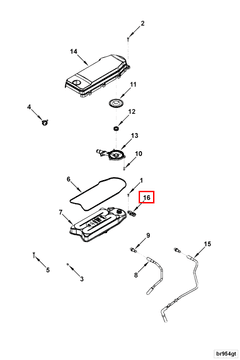

Installation and Integration

Installing the Cummins 4954400 Pressure Sensor involves connecting it to the appropriate pressure points within the truck’s system. It requires careful alignment and secure fastening to ensure accurate readings. Integration into the truck’s systems is straightforward, with the sensor communicating directly with the vehicle’s electronic control unit (ECU) to provide real-time data .

Troubleshooting and Maintenance

Common issues with the Cummins 4954400 Pressure Sensor may include inaccurate readings or sensor failure. Troubleshooting involves checking the sensor’s connections, ensuring it is properly aligned, and verifying that there are no obstructions or damage. Regular maintenance includes inspecting the sensor for signs of wear or corrosion and ensuring that all connections are secure. This helps ensure the longevity and optimal performance of the sensor .

Performance Monitoring and Diagnostics

The Cummins 4954400 Pressure Sensor plays a role in performance monitoring and diagnostics by providing continuous pressure data to the truck’s systems. This data is used by the ECU to make adjustments to engine performance, fuel delivery, and other critical functions. It also aids in diagnostics by helping identify potential issues before they become serious problems, allowing for timely maintenance and repairs .

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a long history of producing high-quality engines and components. The company is known for its expertise in engine technology and its commitment to innovation and reliability. Cummins has established a strong reputation in the industry for delivering products that meet the demanding requirements of commercial truck applications .

Compatibility with Cummins Engines

This Cummins part is designed to be compatible with a range of Cummins engines. Below is a detailed look at the compatibility of this sensor with various Cummins engines:

ISB Series

- ISB (Chrysler)

- ISB CM2150

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISC Series

- ISC CM2150

- ISC8.3 CM2250

ISL Series

- ISL CM2150

- ISL9 CM2250

ISM Series

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

ISX Series

- ISX CM871

- ISX15 CM2250

- ISX15 CM2350 X101

QSB Series

- QSB6.7 CM2250

- QSB6.7 M CM2250

QSC and QSL Series

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

QSM Series

- QSM11 CM876

QSX Series

- QSX15 CM2250 ECF

This part is engineered to fit seamlessly within these engines, ensuring that pressure readings are accurate and reliable. This compatibility is crucial for maintaining engine efficiency and performance across various applications and conditions .

Role of 4954400 Pressure Sensor in Engine Systems

The 4954400 Pressure Sensor is an essential component in various engine systems, contributing to the overall efficiency and performance of the engine.

In the crankcase breather system, the pressure sensor monitors the pressure levels within the crankcase. This is vital for maintaining optimal pressure, which ensures that the crankcase breather functions correctly. Proper breather operation prevents the buildup of harmful gases and moisture, which can lead to engine wear and reduced performance.

When integrated with the valve cover blowby sensor kit, the pressure sensor helps in detecting any abnormal pressure changes that may indicate issues such as blowby. This early detection allows for timely maintenance, thereby prolonging the engine’s lifespan and ensuring consistent performance.

In the context of a long block or long block kit, the pressure sensor plays a role in monitoring the internal pressures of the engine. This is particularly important in ensuring that all components within the long block, such as the crankshaft and pistons, operate within safe pressure limits.

The engine control module (ECM) relies on data from the pressure sensor to make real-time adjustments to the engine’s operation. By providing accurate pressure readings, the sensor enables the ECM to optimize fuel delivery, ignition timing, and other critical parameters, leading to improved efficiency and reduced emissions.

Overall, the 4954400 Pressure Sensor is a key component in maintaining the health and performance of various engine systems, ensuring that they operate smoothly and efficiently.

Conclusion

The Cummins 4954400 Pressure Sensor is a vital component in the operation of commercial trucks, providing accurate pressure readings that contribute to engine efficiency, safety, and performance. Its robust design, compatibility with various Cummins engines, and integration into critical engine systems make it an indispensable part of modern truck technology.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Cummins Inc. (n.d.). Service Manual (5676983). B4.5 CM2620 B180B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.