This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4982294 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the engine’s belt-driven system, contributing to the efficient operation of various engine accessories. Understanding its purpose and significance can help in maintaining the overall performance and reliability of the vehicle.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt-driven systems to guide and maintain tension in the belt. It does not directly drive any component but plays a role in ensuring the belt remains properly aligned and tensioned. This helps in the efficient transfer of power from the engine to various accessories such as the alternator, water pump, and air conditioning compressor 1.

Purpose of the 4982294 Idler Pulley

The Cummins 4982294 Idler Pulley is specifically designed to maintain the correct tension and alignment of the belt in the engine’s accessory drive system. By doing so, it ensures that the belt operates efficiently, reducing the risk of slippage and wear. This component helps in distributing the load evenly across the belt, which is important for the reliable operation of engine accessories 2.

Key Features

This part is constructed from high-quality materials to ensure durability and performance. Its design includes precision-machined surfaces to minimize friction and wear. Additionally, it may feature a bearing system that allows for smooth rotation, reducing the stress on the belt and other components in the system 3.

Benefits of Using the 4982294 Idler Pulley

Utilizing the Cummins 4982294 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment. This reduces wear on the belt and other components, leading to enhanced system efficiency. Additionally, the smooth operation of the idler pulley can help in reducing noise and vibration within the engine compartment 4.

Installation Considerations

When installing the 4982294 Idler Pulley, it is important to follow guidelines to ensure proper function. This includes aligning the pulley correctly within the belt path, using the specified torque for fastening, and ensuring that all preparatory steps, such as cleaning the mounting area, are completed. Proper installation is key to achieving the intended performance benefits.

Troubleshooting Common Issues

Common issues with idler pulleys can include noise, wear, and misalignment. These problems can often be traced back to improper installation, lack of maintenance, or normal wear and tear. Troubleshooting steps may involve inspecting the pulley for signs of damage, ensuring it is properly aligned, and checking the tension of the belt.

Maintenance Tips

Regular maintenance of the 4982294 Idler Pulley is important for ensuring its longevity and performance. This includes periodic inspections for signs of wear, ensuring the pulley is properly lubricated if required, and replacing it if any damage is detected. Adhering to manufacturer-recommended maintenance intervals can help in preventing unexpected failures.

Role in the Belt Drive System

The 4982294 Idler Pulley interacts with other components in the belt drive system, such as the crankshaft pulley, tensioner, and various driven components. Its role is to guide the belt and maintain tension, ensuring that power is efficiently transferred to engine accessories. This interaction is important for the harmonious operation of the entire system.

Impact on Engine Performance

The proper function of the 4982294 Idler Pulley contributes to overall engine performance by ensuring that the belt drive system operates efficiently. This can lead to improved reliability and longevity of the engine and its accessories. A well-maintained idler pulley can help in reducing the likelihood of belt-related issues, which can otherwise lead to engine downtime.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to quality and innovation is reflected in its extensive product lineup, which includes components like the 4982294 Idler Pulley.

Idler Pulley Part 4982294 Compatibility with Cummins Engines

The Idler Pulley part number 4982294, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part plays a role in the engine’s accessory drive system, ensuring the proper functioning of components such as the alternator, water pump, and air conditioning compressor.

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

- ISBE CM2150

- ISBE4 CM850

The Idler Pulley 4982294 is compatible with the ISB series engines, which are known for their robust performance and reliability. These engines are often used in heavy-duty applications, including commercial vehicles and industrial machinery.

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The Idler Pulley 4982294 is also suitable for the QSB series engines, which are designed for a range of applications from agricultural equipment to construction machinery. These engines are valued for their efficiency and durability.

QSF Series Engines

- QSF2.8 CM2880 F105

- QSF2.8 CM2880 F114

Lastly, the Idler Pulley 4982294 fits the QSF series engines, which are typically used in smaller, more compact machinery. Despite their smaller size, these engines are engineered to deliver reliable performance and efficiency.

Role of Part 4982294 Idler Pulley in Engine Systems

The 4982294 Idler Pulley is a vital component in maintaining the efficiency and reliability of various engine systems. Its primary function is to support the serpentine belt, ensuring it remains taut and properly aligned as it drives multiple engine accessories.

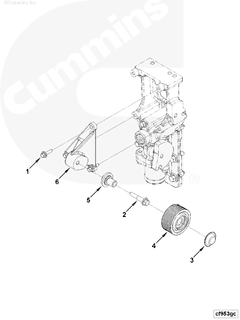

Idler Pulley Location

In most engine configurations, the idler pulley is strategically positioned to provide the necessary tension and redirection of the serpentine belt. It works in conjunction with the tensioner pulley to maintain the correct belt tension, which is important for the smooth operation of all driven components. The idler pulley’s location allows it to assist in navigating the belt around complex engine layouts, ensuring that the belt does not slip or become misaligned.

Refrigerant Compressor

One of the key components driven by the serpentine belt is the refrigerant compressor. The 4982294 Idler Pulley plays a role in this system by ensuring that the belt remains properly tensioned as it drives the compressor. This is particularly important in maintaining the efficiency of the air conditioning system. Proper belt tension ensures that the compressor operates smoothly, providing consistent cooling performance. The idler pulley helps in reducing wear and tear on the belt, thereby extending the lifespan of both the belt and the compressor.

Conclusion

The Cummins 4982294 Idler Pulley is integral to the functioning of engine systems by ensuring the serpentine belt operates efficiently. Its role in supporting the belt and maintaining tension is important for the reliable operation of components such as the refrigerant compressor. Regular maintenance and proper installation of this part can lead to improved engine performance and longevity.

-

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Reif, Konrad. Automotive Mechatronics. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.