This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

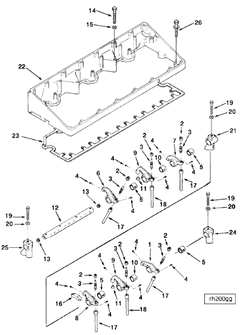

The Rocker (Top Level Assembly) Lever, part number 3070188, manufactured by Cummins, is a critical component in the operation of truck engines. This part is essential for the efficient functioning of the engine’s valve train system, ensuring that the valves open and close at the precise moments required for optimal engine performance.

Basic Concepts

The Rocker (Top Level Assembly) Lever operates based on the principles of mechanical advantage and motion transfer within an internal combustion engine. It acts as a lever that amplifies the motion of the camshaft to open and close the engine’s valves, ensuring that the air-fuel mixture enters the combustion chamber at the right time and that exhaust gases are expelled efficiently 1.

Purpose and Function

The Rocker (Top Level Assembly) Lever is integral to the operation of a truck engine, transferring motion from the camshaft to the valves. This ensures that the valves open and close in sync with the engine’s cycles. It interacts with the camshaft, pushrods, and valves, facilitating the precise timing necessary for combustion. Its function is vital for maintaining engine efficiency, power output, and overall performance 2.

Key Features

The Rocker (Top Level Assembly) Lever is characterized by several key features that enhance its performance and durability. It is typically constructed from high-strength materials such as forged steel or alloy, ensuring it can withstand the high stresses and temperatures within the engine. The design includes precise machining for smooth operation and longevity. Additionally, it may feature roller tips to reduce friction and wear, contributing to improved engine efficiency and longevity 3.

Benefits

The Rocker (Top Level Assembly) Lever offers several advantages that contribute to enhanced engine performance. Its robust construction and precise engineering result in durable operation under high-stress conditions. The reduction in friction due to roller tips, if present, leads to improved efficiency and reduced wear on other engine components. Furthermore, its reliable operation ensures consistent valve timing, which is crucial for maintaining engine performance and fuel efficiency 4.

Installation and Integration

Proper installation of the Rocker (Top Level Assembly) Lever is essential for ensuring its effective operation within the engine assembly. The installation process involves careful alignment with the camshaft and pushrods to ensure smooth and precise motion transfer. It is important to follow manufacturer guidelines to avoid misalignment, which could lead to valve train noise, reduced performance, or even engine damage. Torque specifications and clearance checks are essential steps in the installation process to ensure optimal function 5.

Maintenance and Troubleshooting

Regular maintenance of the Rocker (Top Level Assembly) Lever is necessary to ensure its continued reliable operation. This includes periodic inspection for wear, proper lubrication, and clearance checks. Common issues may include noise from the valve train, which could indicate wear or misalignment. Troubleshooting involves checking for proper installation, ensuring correct clearances, and addressing any signs of wear or damage promptly to prevent further engine issues .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and customer satisfaction in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and excellence makes it a trusted name among fleet operators and engine manufacturers.

Compatibility

The Rocker (Top Level Assembly) Lever part number 3070188 is designed to fit seamlessly with a range of engine models. This part is crucial for the proper functioning of the engine’s valve train system, ensuring smooth and efficient operation.

L10 CELECT Engines

The L10 CELECT engines are among the models that benefit from the precise engineering of the 3070188 Rocker (Top Level Assembly) Lever. This part is specifically engineered to meet the demands of these engines, providing durability and reliability under various operating conditions.

Grouping by Engine Series

The 3070188 Rocker (Top Level Assembly) Lever is compatible with the following engine series:

- L10 CELECT Engines: This series includes engines that are known for their robust performance and efficiency. The 3070188 part ensures that these engines maintain optimal valve timing and pressure, contributing to their overall longevity and efficiency.

Application in Engine Systems

In the L10 CELECT engines, the 3070188 Rocker (Top Level Assembly) Lever plays a pivotal role in the valve train system. It is responsible for transferring motion from the camshaft to the valve, ensuring that the valves open and close at the correct times. This synchronization is critical for the engine’s performance, as it affects combustion efficiency and power output.

Importance of Proper Fitment

Ensuring that the 3070188 Rocker (Top Level Assembly) Lever is correctly fitted is essential for maintaining the integrity of the engine’s valve train. Any misalignment or wear in this component can lead to increased valve clearance, which can result in poor engine performance, increased fuel consumption, and potential engine damage over time.

Compatibility Considerations

When replacing or servicing the 3070188 Rocker (Top Level Assembly) Lever, it is important to verify compatibility with the specific engine model. This ensures that the part will fit correctly and function as intended, maintaining the engine’s performance and reliability.

Component Usage

The part 3070188 Rocker (Top Level Assembly) Lever is an integral component in the operation of engine systems, particularly in the valve train mechanism. This lever is designed to convert the rotational motion of the camshaft into the linear motion required to open and close the engine’s valves.

Integration with Engine Components

- Camshaft Interaction: The Rocker (Top Level Assembly) Lever interfaces directly with the camshaft. As the camshaft rotates, it pushes against the lever, initiating the motion transfer process.

- Valve Actuation: The primary function of the lever is to actuate the valves. When the camshaft lobe contacts the lever, it pivots, transferring motion to the valve stem via the pushrod or directly, depending on the engine design. This action ensures precise timing for the intake and exhaust valves, optimizing engine performance.

- Pushrod Mechanism: In overhead valve (OHV) engines, the Rocker (Top Level Assembly) Lever works in conjunction with pushrods. The pushrod transmits the motion from the camshaft to the lever, which then amplifies this motion to open the valve.

- Valve Spring Interaction: After the valve is opened, the valve spring plays a role in returning the valve to its closed position. The lever must be designed to withstand the forces exerted by the valve spring, ensuring reliable and consistent valve operation.

- Valve Clearance Adjustment: The lever assembly often includes provisions for adjusting valve clearance. This is essential for maintaining optimal valve operation over the engine’s lifespan, as wear and thermal expansion can affect clearances.

- Hydraulic Lifters: In engines equipped with hydraulic lifters, the Rocker (Top Level Assembly) Lever works with these components to maintain zero valve clearance. The lever ensures that the hydraulic lifter’s motion is effectively transferred to the valve, accommodating any changes in valve seat height due to wear.

- Overhead Cam (OHC) Engines: In overhead cam engines, the lever may be part of a rocker arm assembly that directly contacts the camshaft. This setup eliminates the need for pushrods, reducing the number of moving parts and potentially improving engine efficiency and responsiveness.

- Material and Design Considerations: The lever is typically made from high-strength materials to endure the repetitive stresses and high temperatures within the engine compartment. Its design must balance durability with minimal weight to reduce inertia and enhance engine performance.

Understanding the role of the part 3070188 Rocker (Top Level Assembly) Lever in these engine systems highlights its significance in ensuring smooth and efficient valve operation, which is fundamental to the overall performance and longevity of the engine.

Conclusion

The Rocker (Top Level Assembly) Lever, part number 3070188, is a vital component in the operation of truck engines, particularly within the valve train system. Its design and function are crucial for ensuring that the valves open and close at the precise moments required for optimal engine performance. Proper installation, regular maintenance, and understanding its integration with other engine components are essential for maintaining engine efficiency, power output, and overall performance. Cummins’ commitment to quality and innovation ensures that this part meets the demanding requirements of heavy-duty applications, making it a reliable choice for fleet operators and engine manufacturers.

-

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics (Creative Commons, 2024).

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects (Routledge, 2023).

↩ -

Robert Huzij, Angelo Spano, and Sean Bennett, Modern Diesel Technology Heavy Equipment Systems (Delmar Cengage Learning, 2014).

↩ -

Frederick F. Ling, The Automotive Body (Springer Science, 2011).

↩ -

Cummins Inc., Owners Manual (Engine: F4.5 CM2620 F152C, Bulletin Number: 6324123).

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.