This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4318205 Rocker Lever is a critical component in the operation of heavy-duty trucks. It facilitates the transfer of motion from the camshaft to the valves, contributing to the efficient functioning of the engine.

Basic Concepts of Rocker Levers

A rocker lever, or rocker arm, is a mechanical component that amplifies the motion of the camshaft to open and close the engine’s valves. It operates on the principle of leverage, allowing for precise control over valve timing and lift. This is essential for the engine’s performance and efficiency 1.

Purpose of the 4318205 Rocker Lever

The Cummins 4318205 Rocker Lever is designed to enhance the operation of truck engines by ensuring that the valves open and close with the necessary force and precision. This component is vital for maintaining the engine’s performance, directly influencing the air and fuel mixture’s intake and exhaust processes 2.

Key Features

The Cummins 4318205 Rocker Lever is constructed from high-quality materials, ensuring durability and resistance to wear. Its design includes precise machining for smooth operation and reliable performance. Additionally, it may feature design elements that reduce friction and improve efficiency, such as roller tips or specialized coatings 3.

Benefits

The Cummins 4318205 Rocker Lever offers several advantages. Its robust construction and precise engineering contribute to improved engine efficiency and durability. By ensuring optimal valve timing and force, this component helps maintain the engine’s performance over time. Enhanced design elements may also reduce wear and tear, leading to longer service intervals and reduced maintenance costs 4.

Installation and Integration

Proper installation of the Cummins 4318205 Rocker Lever is crucial for its effective function within the engine system. It should be installed according to the manufacturer’s guidelines, which may include specific torque settings and alignment procedures. Ensuring the rocker lever is correctly positioned and secured will help prevent issues such as valve train noise or reduced engine performance 5.

Troubleshooting Common Issues

Common problems associated with rocker levers can include noise, reduced performance, or valve train issues. These problems may arise from improper installation, wear and tear, or other mechanical failures. Troubleshooting steps may involve inspecting the rocker lever for signs of damage, ensuring proper alignment and torque, and addressing any underlying issues within the valve train system 6.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4318205 Rocker Lever, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring that all fasteners are secure, and following the manufacturer’s service intervals for replacement or overhaul. Additionally, keeping the engine clean and well-lubricated can help reduce friction and wear on the rocker lever and other components 7.

Compatibility of Rocker Lever Part 4318205 with Cummins Engines

The Rocker Lever part 4318205, manufactured by Cummins, is designed to fit a variety of their engine models. This part is integral to the engine’s valve train system, ensuring proper valve operation and overall engine performance.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

QSX Series Engines

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

By ensuring compatibility with these various engine models, the Rocker Lever part 4318205 plays a vital role in the engine’s operation, providing a reliable and efficient solution for valve management across different engine types 8.

Role of Part 4318205 Rocker Lever in Engine Systems

The part 4318205 Rocker Lever is an essential component in the operation of various engine systems. It is primarily responsible for transferring the motion from the camshaft to the valves, ensuring precise and timely valve operation.

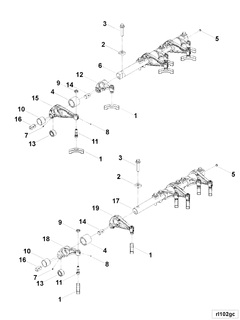

In the context of the rocker lever top-level assembly, the 4318205 Rocker Lever works in conjunction with the camshaft, pushrods, and valve train components. The camshaft, driven by the engine’s timing belt or chain, imparts motion to the pushrods. These pushrods, in turn, transmit this motion to the rocker lever.

The rocker lever then amplifies this motion, applying it to the valves. This mechanism ensures that the valves open and close at the correct intervals, allowing for the intake of the air-fuel mixture and the expulsion of exhaust gases. The precision of the rocker lever’s movement is vital for maintaining engine efficiency and performance.

Additionally, the rocker lever top-level assembly often includes components such as valve springs, valve keepers, and valve seals. The valve springs keep the valves seated when they are not being actuated, while the valve keepers secure the valves in place. The valve seals prevent oil from leaking into the combustion chamber, ensuring that the engine operates smoothly and efficiently.

The integration of the 4318205 Rocker Lever within this assembly highlights its importance in the overall function of the engine. Its role in translating and amplifying camshaft motion to valve action is fundamental to the engine’s operation, directly influencing combustion efficiency and power output 9.

Conclusion

The Cummins 4318205 Rocker Lever is a vital component in the operation of heavy-duty truck engines. Its precise engineering, robust construction, and compatibility with various Cummins engine models ensure optimal valve operation and engine performance. Regular maintenance and proper installation are essential for maximizing the benefits of this component.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4388871.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.