4936172

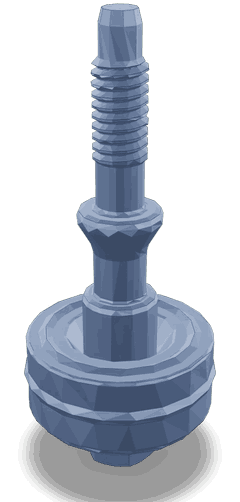

Shoulder Isolator Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Shoulder Isolator Cap Screw, part number 4936172, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part is integral to the mechanical systems of these vehicles, ensuring reliable operation and performance. Cummins, a well-established name in the automotive industry, produces this component with a focus on quality and durability 1.

Basic Concepts

A Shoulder Isolator Cap Screw is a type of fastener that incorporates an isolator feature to reduce vibration and stress on the connected components. The construction of this Cummins part includes a threaded section for secure attachment, a shoulder that provides a stop against over-tightening, and an isolator element that cushions the connection. Within a truck’s mechanical system, this screw plays a role in securing components while mitigating the effects of vibration and mechanical stress 2.

Role and Function

The 4936172 Shoulder Isolator Cap Screw serves multiple functions in the operation of a truck. It secures critical components in place, ensuring they remain fixed during operation. Additionally, the isolator feature helps to dampen vibrations, which can otherwise lead to wear and tear on both the screw and the components it connects. This contributes to the overall performance and reliability of the truck by maintaining secure and stable connections under varying operational conditions 3.

Key Features

Several key features enhance the functionality of the Shoulder Isolator Cap Screw. Its material composition, typically a durable alloy, ensures resistance to corrosion and mechanical stress. The design includes a precisely machined shoulder that prevents over-tightening, protecting the connected components. The isolator element is crafted to provide optimal vibration damping, extending the lifespan of the screw and the components it supports.

Benefits

The use of the Shoulder Isolator Cap Screw offers several advantages. Its robust construction and material composition contribute to improved durability, reducing the frequency of replacements. The isolator feature enhances the performance of the truck by minimizing the impact of vibrations on critical components. Additionally, the reliability and longevity of this screw can lead to potential cost savings for fleet operators by reducing maintenance and replacement costs over time.

Troubleshooting and Maintenance

Common issues with the Shoulder Isolator Cap Screw may include wear on the isolator element or corrosion on the screw threads. Regular inspection and maintenance are recommended to ensure optimal performance. This includes checking for signs of wear or damage, ensuring the screw is properly tightened without over-tightening, and protecting the screw from corrosive environments. Troubleshooting may involve replacing the isolator element or the entire screw if significant wear or damage is detected.

Compatibility

The Cummins Shoulder Isolator Cap Screw, part number 4936172, is compatible with various Cummins engine models, including the B5.6 and B6.7 Series Engines, ISB Series Engines, and QSB Series Engines. This part is designed to secure the engine’s isolator mounts, ensuring stability and reducing vibrations.

Role in Engine Systems

The Shoulder Isolator Cap Screw is integral to the secure assembly and operation of various engine components. It is used to fasten the valve cover securely to the engine block, ensuring that the cover remains in place under the dynamic conditions of engine operation. The screw’s design allows for vibration damping, which is particularly important in high-performance engines where components are subjected to significant stress.

Conclusion

The Shoulder Isolator Cap Screw (part 4936172) is a fundamental component in the secure and efficient assembly of engine systems. Its role in maintaining the structural integrity and operational performance of the engine cannot be overstated. Regular maintenance and proper use of this part are essential for ensuring the longevity and reliability of commercial truck engines.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Vibration Isolator | 1 | 3973853 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.