This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3045878 O-Ring Seal is a component designed to ensure the integrity of fluid systems in commercial trucks. Its purpose is to create a reliable seal in various applications, contributing to the overall efficiency and reliability of the vehicle. Understanding its function and significance is key to maintaining the performance of commercial trucks.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a toroidal (ring-shaped) elastomer with a circular cross-section, used to create a seal between two or more parts. In mechanical systems, O-Rings operate by deforming slightly when compressed between flanges or in a gland, which allows them to fill gaps and prevent fluid or gas leakage. They are widely used due to their simplicity, effectiveness, and versatility in various applications 1.

Purpose of the Cummins 3045878 O-Ring Seal

The Cummins 3045878 O-Ring Seal plays a specific role in the operation of commercial trucks by ensuring the sealing of fluid systems. It is applied in areas where fluid transfer occurs, supporting systems such as fuel lines, hydraulic systems, and coolant circuits. Its function is to maintain system pressure, prevent leaks, and ensure the efficient operation of these systems 2.

Key Features

The Cummins 3045878 O-Ring Seal is characterized by its material composition, typically made from durable elastomers that can withstand high temperatures and pressures. Its design is tailored for heavy-duty applications, featuring a robust construction that ensures longevity and reliability. These features make it well-suited for the demanding conditions encountered in commercial trucking 3.

Benefits

Utilizing the Cummins 3045878 O-Ring Seal offers several advantages, including improved system efficiency through reliable sealing, reduced maintenance needs due to its durability, and enhanced reliability in harsh operating conditions. These benefits contribute to the overall performance and longevity of commercial trucks.

Installation Considerations

Proper installation of the Cummins 3045878 O-Ring Seal is crucial for its optimal performance and longevity. Best practices include ensuring the sealing surfaces are clean and free of debris, using the correct installation tools to avoid damage, and following manufacturer guidelines for torque and compression. These steps help ensure the seal functions effectively and maintains system integrity.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, which can arise from improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting steps involve inspecting the seal for damage, ensuring correct installation, and replacing the seal if necessary. Addressing these issues promptly helps maintain system integrity and prevent further complications.

Maintenance Tips

Regular maintenance of the Cummins 3045878 O-Ring Seal involves inspection routines to check for signs of wear, deformation, or damage. Replacement guidelines suggest monitoring the seal’s condition and replacing it according to the manufacturer’s recommendations or when signs of failure are observed. These practices help prevent failures and extend the service life of the seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins provides high-quality components for the commercial trucking industry, ensuring reliable performance and efficiency in demanding applications.

O-Ring Seal Part 3045878 Compatibility with Cummins Engines

The O-Ring Seal part 3045878, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring a secure seal to prevent leaks and maintain optimal engine performance. Here is a detailed overview of its compatibility across different engine models:

ISC Series

- ISC CM554

- ISC CM850

ISL Series

- ISL CM554

- ISL9 CM2150 SN

ISM Series

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Series

- L10 CELECT

M11 Series

- M11 CELECT

- M11 CELECT PLUS

N14 Series

- N14 CELECT

- N14 CELECT PLUS

QSC Series

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

QSL Series

- QSL9 CM554

QSM Series

- QSM11 CM570

- QSM11 CM876

QSN Series

- QSN14 CM876 N103

QSNT Series

- QSNT14 CM876 N102

This O-Ring Seal is engineered to provide a reliable seal in various engine environments, ensuring that the engines operate efficiently and safely.

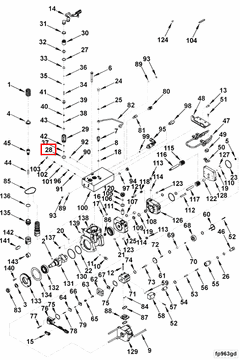

Role of Part 3045878 O-Ring Seal in Engine Systems

The part 3045878 O-Ring Seal is integral to the reliable operation of various engine components. Its primary function is to ensure a secure and leak-free seal in applications where fluid or gas containment is essential.

In the solenoid valve, the O-Ring Seal prevents fluid leakage between the valve body and the plunger, maintaining the integrity of the hydraulic or pneumatic system.

Within the accumulator and accumulator module, it seals the interface between moving parts, ensuring that the stored energy in the form of pressurized fluid is not lost.

The actuator cover relies on the O-Ring Seal to prevent any escape of hydraulic fluid, which is vital for the actuator’s precise movement and control.

For the air intake connection, the seal ensures that the air-fuel mixture remains uncontaminated by external elements, which is crucial for combustion efficiency.

In the body & plunger assembly, the O-Ring Seal is positioned to prevent leaks at the connection points, ensuring consistent performance of the plunger mechanism.

The campaign kit often includes O-Ring Seals to address common wear and tear issues in various engine components, enhancing the kit’s effectiveness in maintaining engine health.

The camshaft and connecting rod assemblies may incorporate O-Ring Seals in lubrication systems to ensure oil does not leak, thus preserving the longevity and efficiency of these components.

For the EBM-Injector and EBM-Performance Parts, the O-Ring Seal is used to maintain the precision of fuel delivery by sealing the injector body and ensuring no fuel leakage occurs.

In the fuel injection pump and fuel pump, the seal is critical for maintaining pressure and preventing fuel leaks, which are essential for the reliable operation of the fuel system.

The hotstart start kit and injector components also benefit from the O-Ring Seal by ensuring that the fuel system remains pressurized and leak-free, facilitating easier engine starts in cold conditions.

The pressure relief valve uses the O-Ring Seal to maintain the integrity of the valve seating, ensuring that the system can safely release excess pressure without leakage.

Overall, the part 3045878 O-Ring Seal plays a significant role in enhancing the performance and reliability of these engine components by providing essential sealing functions.

Conclusion

The Cummins 3045878 O-Ring Seal is a critical component in the maintenance and operation of commercial trucks. Its role in ensuring the integrity of fluid systems, combined with its durability and compatibility with a wide range of Cummins engines, makes it an essential part for maintaining engine efficiency and reliability. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.