4088175

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

O Ring Seals are circular elastomeric components designed to create a seal between two or more mating surfaces. They are widely used in mechanical systems to prevent the leakage of fluids and gases, ensuring system integrity. O Ring Seals function based on the principle of compression, where the ring is compressed between two surfaces to create a tight seal. They are versatile and can be used in both dynamic and static applications, making them indispensable in various industries, including automotive and heavy-duty truck manufacturing 1.

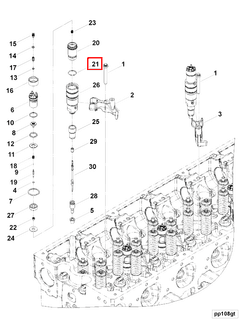

Purpose of Cummins 4088175 O Ring Seal in Truck Operations

The Cummins 4088175 O Ring Seal is specifically designed to play a role in the operational framework of commercial trucks. It is employed in environments where sealing is crucial to prevent fluid or gas leakage, which can lead to system failure or inefficiency. This part is typically used in systems where precise sealing is required to maintain the performance and reliability of the truck’s components 2.

Key Features of Cummins 4088175 O Ring Seal

The Cummins 4088175 O Ring Seal is characterized by several key features that contribute to its effectiveness and durability. It is made from high-quality elastomeric material, which provides excellent resistance to various environmental factors such as temperature fluctuations, chemical exposure, and mechanical stress. The dimensional specifications of the seal are precisely engineered to ensure a snug fit within the application, enhancing its sealing capabilities. Additionally, any unique design aspects, such as specific cross-sectional shapes or surface treatments, further improve its performance in demanding conditions.

Benefits of Using Cummins 4088175 O Ring Seal

The Cummins 4088175 O Ring Seal offers several advantages that enhance the overall performance and efficiency of truck systems. Its superior sealing performance helps prevent leaks, ensuring that fluids and gases remain contained within the system. The seal’s longevity is enhanced by its durable material composition and precise design, reducing the need for frequent replacements. Furthermore, its resistance to environmental factors ensures consistent performance over time, contributing to the reliability of the truck’s components.

Installation and Maintenance Guidelines

Proper installation of the Cummins 4088175 O Ring Seal is vital to ensure optimal performance. It should be installed in a clean, lubricated groove to prevent damage and ensure a proper seal. Regular maintenance and inspection are recommended to prolong the lifespan of the seal. This includes checking for signs of wear, deformation, or damage and replacing the seal as necessary to prevent common issues such as leaks or failures.

Troubleshooting Common Issues

Typical problems associated with O Ring Seals include leaks or failures, which can often be traced back to incorrect installation, environmental stress, or wear and tear. Systematic approaches to diagnosing these issues involve inspecting the seal for physical damage, ensuring proper installation, and assessing the environmental conditions in which the seal operates. Correct diagnosis and appropriate corrective actions are important to resolve these issues effectively.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive and engine manufacturing industry. The company’s focus on research and development ensures that its products, including the Cummins 4088175 O Ring Seal, meet the highest standards of performance and reliability.

Compatibility of Cummins 4088175 O Ring Seal with Cummins Engines

The Cummins 4088175 O Ring Seal is designed to fit a variety of Cummins engines, ensuring a secure seal in critical areas. Here is a detailed look at its compatibility with the listed engines:

ISC Series

- ISC CM554

- ISC CM850

The O Ring Seal is compatible with the ISC series engines, providing essential sealing for components such as fuel injectors and other fluid pathways.

ISL Series

- ISL CM554

- ISL9 CM2150 SN

This part is also suitable for the ISL series, ensuring that high-pressure systems maintain their integrity and preventing leaks.

ISM Series

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines benefit from the O Ring Seal, which is crucial for maintaining the seal in various engine components, including turbochargers and fuel systems.

ISX Series

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

The ISX series engines, known for their high performance and power, utilize the O Ring Seal to ensure that all critical seals are intact, preventing any potential fluid leaks.

ISZ Series

- ISZ13 CM2150 Z105

The ISZ series engine also integrates the O Ring Seal, ensuring that all components requiring sealing are properly sealed.

Celect Series

- L10 CELECT

- M11 CELECT

- M11 CELECT PLUS

- N14 CELECT PLUS

The Celect series engines, designed for specific applications, use the O Ring Seal to maintain the necessary seals for optimal performance.

QSC and QSL Series

- QSC8.3 CM554

- QSL9 CM554

The QSC and QSL series engines also incorporate the O Ring Seal, ensuring that all fluid pathways and critical components are sealed effectively.

QSM and QSNT Series

- QSM11 CM570

- QSM11 CM876

- QSN14 CM876 N103

- QSNT14 CM876 N102

The QSM and QSNT series engines utilize the O Ring Seal to maintain the integrity of seals in various engine components.

QSX Series

- QSX11.9 CM2250 ECF

The QSX series engine also relies on the O Ring Seal to ensure that all seals are intact, preventing leaks and maintaining engine efficiency.

Role of Part 4088175 O Ring Seal in Engine Systems

The 4088175 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a significant role in the overall performance and reliability of the engine.

Fuel Systems

In the Fuel Injection Pump and Fuel Systems HD XPI, the O Ring Seal is utilized to prevent fuel leaks and maintain the precise fuel delivery required for optimal engine performance. It ensures that the fuel pressure remains consistent, which is vital for the efficient operation of the Injectors and Injector Plumbing.

Engine Components

Within the Cylinder Head and Engine Piston Kit, the O Ring Seal is employed to create a tight seal between moving parts. This is particularly important in the Connecting Rod and Piston assembly, where it helps to maintain the integrity of the combustion chamber and prevent oil leaks.

Camshaft and Valve Train

The Cam Housing Module and Camshaft also benefit from the use of the O Ring Seal. It ensures that the valve train components operate smoothly without any lubricant leakage, which is essential for the longevity and performance of these parts.

Cooling and Plumbing Systems

In the Water Manifold and Solenoid Valve, the O Ring Seal plays a key role in maintaining the coolant flow and pressure. This is critical for the efficient cooling of engine components, thereby preventing overheating and ensuring consistent engine operation.

Performance and Overhaul Kits

The Lower Engine Gasket Kit and Overhaul Kit often include the O Ring Seal to ensure that all gaskets and seals are in optimal condition. This is particularly important during engine rebuilds or major repairs, where the integrity of every seal can significantly impact the engine’s performance and longevity.

Specialized Systems

For systems like the XPI JV System Cummins HD and XPI JV System Scania HD, the O Ring Seal is used to maintain the high-pressure fuel delivery systems. This ensures that the fuel is delivered at the correct pressure and timing, which is essential for the performance of these high-demand engines.

Additional Applications

The O Ring Seal is also found in the Accumulator, Body & Plunger, and Pressure Relief Valve. In these components, it helps to maintain system pressure and prevent leaks, ensuring that the engine operates within its designed parameters.

Conclusion

The Cummins 4088175 O Ring Seal is a versatile component that enhances the functionality and reliability of various engine systems. Its proper installation and maintenance are key to ensuring the engine’s optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.