Introduction

The Cummins 3085244 Pressure Sensor is designed to monitor and regulate pressure levels within a commercial truck’s system, ensuring efficient and safe operation by providing accurate pressure readings to the truck’s control systems 1.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid on a surface, converting this physical pressure into an electrical signal for interpretation by vehicle electronic systems. They are used in various automotive applications, including fuel injection, brake systems, and engine management, to maintain system operation within designed parameters 2.

Role of the 3085244 Pressure Sensor in Truck Operation

This Cummins part monitors system pressure, integrating with the truck’s electronic control unit (ECU) to provide real-time data for adjustments, ensuring optimal performance in systems like fuel delivery and braking 1.

Key Features of the 3085244 Pressure Sensor

Characterized by robust design and high-quality materials, this part ensures durability and reliability. It incorporates technological advancements for improved accuracy and resistance to environmental factors 1.

Benefits of Using the 3085244 Pressure Sensor

Incorporating this part into a truck’s system improves efficiency, enhances reliability through accurate data for timely adjustments, and contributes to safety by ensuring critical systems operate correctly 1.

Installation and Integration

Proper installation of this part is crucial for effective operation. Best practices include correct alignment, secure fastening, and proper wiring to the ECU. Avoiding common pitfalls like incorrect alignment and loose connections ensures functionality 1.

Troubleshooting Common Issues

Common issues with this part include inaccurate readings and sensor failure. Troubleshooting involves checking alignment, connections, and electrical circuit continuity. Solutions may include realignment, reconnection, or replacement 1.

Maintenance Tips

Regular maintenance of this part, including inspection, cleaning, and functionality testing, ensures longevity and optimal performance, preventing issues and ensuring accurate pressure readings 1.

Cummins: A Brief Overview

Cummins Inc. is a global leader in engines, filtration, and power generation products, with a history of over a century in the commercial truck industry. Its commitment to innovation and quality has established it as a trusted name 1.

Cummins Pressure Sensor 3085244 in Engine Applications

This part is critical in engine systems of several Cummins models, ensuring optimal performance by accurately measuring engine system pressure.

QSK19 CM500

In the QSK19 CM500 engine, this part monitors pressure levels within the fuel and exhaust systems, ensuring efficient and safe operation.

Grouped Engine Models

This part is utilized in various Cummins engines, including QSK19, QSK38, and QSK60, enhancing engine reliability and performance through precise pressure readings 1.

Role of Part 3085244 Pressure Sensor in Engine Systems

This part is integral to modern engine systems, interacting with the Engine Control Module (ECM) to monitor and report pressure levels within engine components, ensuring optimal performance and efficiency.

Interaction with the Engine Control Module (ECM)

The ECM uses data from this part to optimize fuel injection, manage turbocharger performance, enhance emissions control, and monitor oil pressure, ensuring proper engine operation 2.

Broader System Integration

Beyond ECM interaction, this part plays a role in the fuel, exhaust, and cooling systems, contributing to overall engine efficiency and performance 2.

Conclusion

The Cummins 3085244 Pressure Sensor is a vital component in commercial truck and engine systems, ensuring optimal performance, efficiency, and safety through accurate pressure monitoring and data provision to control systems.

SPECIFICATIONS

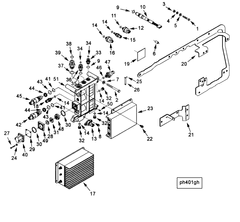

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Pressure Sensor | 1 | 3085245 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.