This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3085245 Pressure Sensor is a component designed to monitor and measure pressure levels within a commercial truck’s engine system. Its purpose is to provide accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is significant in commercial truck operations as it helps maintain optimal engine performance and ensures that the truck operates within safe parameters.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic systems. In automotive applications, pressure sensors are used to monitor various systems such as fuel injection, turbocharging, and engine lubrication. They play a role in ensuring that these systems operate efficiently and safely by providing real-time data to the engine management system 1.

Role of the 3085245 Pressure Sensor in Truck Operation

The Cummins 3085245 Pressure Sensor is integrated into the engine management system of a commercial truck. It measures the pressure within specific components of the engine, such as the fuel system or turbocharger. By providing precise pressure readings, the sensor allows the engine management system to make adjustments to fuel delivery, air intake, and other critical functions. This integration helps in optimizing engine performance, improving fuel efficiency, and ensuring that the engine operates within its designed parameters 2.

Key Features of the 3085245 Pressure Sensor

The Cummins 3085245 Pressure Sensor is characterized by its robust design and high-quality materials, which contribute to its durability and reliability. The sensor is constructed using materials that can withstand the harsh conditions within a commercial truck engine. Its technological specifications include a high level of accuracy in pressure measurement, fast response times, and the ability to operate under a wide range of temperatures. These features enhance the sensor’s performance and ensure consistent and reliable operation 3.

Benefits of Using the 3085245 Pressure Sensor

Incorporating the Cummins 3085245 Pressure Sensor into a truck’s system offers several advantages. It contributes to improved engine efficiency by ensuring that the engine operates under optimal conditions. The sensor also enhances safety by providing accurate pressure readings that help prevent engine damage due to overpressure or underpressure conditions. Additionally, the reliable performance of the sensor ensures that the truck can operate consistently, reducing the likelihood of unexpected downtime.

Installation and Integration

Proper installation and integration of the Cummins 3085245 Pressure Sensor into a truck’s system are important for ensuring its effective operation. Installation should be carried out according to the manufacturer’s guidelines, which may include specific mounting locations and electrical connections. It is also important to ensure that the sensor is compatible with the truck’s engine management system to ensure seamless integration and accurate data transmission.

Troubleshooting Common Issues

Common problems associated with pressure sensors can include inaccurate readings, sensor failure, or electrical issues. Potential causes may range from physical damage to the sensor, wiring problems, or software glitches within the engine management system. Recommended troubleshooting steps include checking the sensor for physical damage, verifying electrical connections, and ensuring that the engine management system software is up to date. If issues persist, consulting the manufacturer’s troubleshooting guide or seeking professional assistance may be necessary.

Maintenance Tips

To ensure the longevity and consistent performance of the Cummins 3085245 Pressure Sensor, regular maintenance is recommended. This includes periodic checks for physical damage, ensuring that electrical connections are secure, and cleaning the sensor as necessary to remove any contaminants that may affect its operation. Adhering to these best practices helps in maintaining the sensor’s accuracy and reliability over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing high-quality, reliable, and efficient products. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Pressure Sensor 3085245 in Engine Applications

The Cummins Pressure Sensor 3085245 is a critical component in various engine applications, ensuring optimal performance and efficiency. This sensor is designed to monitor and regulate pressure levels within the engine’s systems, providing essential data to the engine control unit (ECU).

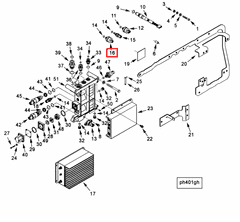

QSK19 CM500

In the QSK19 CM500 engine, the Pressure Sensor 3085245 plays a pivotal role in maintaining the engine’s operational integrity. It is strategically placed to monitor pressure in key areas, ensuring that the engine operates within safe parameters. This sensor’s accurate readings are vital for the ECU to make real-time adjustments, enhancing fuel efficiency and reducing emissions.

Grouping of Engines

For engines within the same family or similar configurations, the Pressure Sensor 3085245 is a common component. Its design and functionality are tailored to fit seamlessly into the engine’s architecture, ensuring compatibility and reliability across different models. This standardization allows for easier maintenance and repair, as technicians can use familiar procedures and parts across various engine types.

The Pressure Sensor 3085245’s integration into these engines highlights Cummins’ commitment to quality and performance. By using a single, reliable part across multiple models, Cummins ensures that each engine benefits from the same level of precision and durability.

Role of Part 3085245 Pressure Sensor in Engine Systems

Part 3085245, a Pressure Sensor, is integral to the operation of modern engine systems. Its primary function is to measure the pressure within various components and systems, providing essential data that the Engine Control Module (ECM) uses to optimize engine performance.

Interaction with the Engine Control Module (ECM)

The Pressure Sensor continuously monitors pressure levels and sends this data to the ECM. The ECM, in turn, uses this information to make real-time adjustments to fuel injection, ignition timing, and other critical parameters. This ensures that the engine operates efficiently under varying conditions.

Enhancing Fuel Efficiency and Performance

By providing accurate pressure readings, the Pressure Sensor allows the ECM to fine-tune the air-fuel mixture. This results in improved fuel efficiency and enhanced engine performance. The sensor’s data helps prevent issues such as misfires and incomplete combustion, which can lead to decreased power output and increased emissions.

Supporting Emission Control Systems

The Pressure Sensor also plays a role in emission control systems. Accurate pressure data enables the ECM to manage the operation of components like the Exhaust Gas Recirculation (EGR) valve and the Positive Crankcase Ventilation (PCV) system. This helps reduce harmful emissions and ensures the engine meets environmental regulations.

Facilitating Diagnostic Processes

In the event of engine malfunctions, the Pressure Sensor provides valuable diagnostic data. The ECM can use this information to identify issues such as leaks, blockages, or component failures. This facilitates quicker and more accurate troubleshooting, reducing downtime and repair costs.

Integration with Other Systems

Beyond the ECM, the Pressure Sensor interacts with various other engine systems. For example, it works with the turbocharger system to monitor boost pressure, ensuring optimal performance and preventing overboosting. It also supports the operation of the Variable Valve Timing (VVT) system by providing pressure data that helps the ECM adjust valve timing for better efficiency and power.

Conclusion

In summary, the Cummins 3085245 Pressure Sensor is a key component in modern engine systems, enhancing performance, efficiency, and emissions control through its precise pressure measurements and continuous data feedback to the ECM.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.