This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3803240 Viscosity Sensor Kit is a specialized component designed to monitor and maintain the viscosity of engine oil in heavy-duty trucks. This sensor kit plays a role in ensuring that the engine operates under optimal lubrication conditions, which is vital for the longevity and efficiency of the engine 1.

Functionality of the Viscosity Sensor Kit

This Cummins part operates by measuring the viscosity of the engine oil as it circulates through the engine. The sensor uses principles of viscosity measurement to determine the thickness of the oil, which can change due to temperature variations and the accumulation of contaminants. This data is then integrated into the truck’s systems, allowing for real-time adjustments to maintain optimal lubrication 2.

Role in Truck Operation

In the operation of a truck, the viscosity sensor kit plays a role by providing continuous data on the condition of the engine oil. This information helps in maintaining engine performance by ensuring that the oil viscosity remains within the desired range. Proper lubrication reduces friction and wear on engine components, contributing to overall fuel efficiency and engine longevity 3.

Key Features

The Cummins 3803240 is characterized by several key features. It offers precision measurement capabilities, ensuring accurate readings of oil viscosity. The kit is designed with durability in mind, capable of withstanding the harsh conditions typical of heavy-duty truck environments. Additionally, it is specifically engineered for compatibility with Cummins engines, ensuring seamless integration and operation.

Benefits of Using the Viscosity Sensor Kit

Utilizing the Cummins 3803240 offers several advantages. It contributes to improved engine lubrication, which is fundamental for maintaining engine health and performance. The kit also aids in enhancing overall truck performance by ensuring that the engine operates under optimal conditions. Furthermore, it can lead to potential cost savings through better maintenance practices, as it allows for more informed decisions regarding oil changes and engine care.

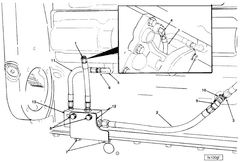

Installation Process

Installing the Cummins 3803240 involves a series of steps to ensure proper setup. It begins with locating the appropriate position within the engine system for the sensor. Following this, the sensor is connected to the engine’s lubrication system, and electrical connections are made to integrate it with the truck’s monitoring systems. Specific requirements for installation may include ensuring the sensor is securely mounted and that all connections are tight and correctly aligned.

Maintenance and Troubleshooting

Maintaining the Cummins 3803240 involves regular checks to ensure it remains in good working condition. This includes verifying the sensor’s calibration and ensuring there are no obstructions or damage to the sensor or its connections. Troubleshooting common issues may involve checking for proper electrical connections, ensuring the sensor is correctly positioned, and verifying that the readings are within expected parameters.

Integration with Other Systems

The Cummins 3803240 interacts with other components and systems within the truck, such as the engine control unit (ECU) and lubrication systems. It provides valuable data to the ECU, which can then make adjustments to engine operation based on the viscosity readings. This integration ensures that the engine operates under optimal conditions, enhancing performance and efficiency.

Impact on Fuel Efficiency

The viscosity sensor kit contributes to improved fuel efficiency by ensuring optimal lubrication conditions within the engine. By maintaining the correct viscosity of the engine oil, friction between moving parts is reduced, which can lead to lower fuel consumption. This is particularly important in heavy-duty trucks, where fuel efficiency is a key consideration for operational costs.

Manufacturer - Cummins

Cummins Inc. is a well-established manufacturer in the automotive industry, with a strong reputation for producing high-quality heavy-duty truck components. The company has a broad product range that includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and quality is evident in their product offerings, including the Cummins 3803240.

Components of Cummins 3803240

The Cummins 3803240 is designed to ensure accurate viscosity measurements in fluid systems, crucial for maintaining optimal performance and safety. Each component within this kit plays a specific role in facilitating the installation and operation of the viscosity sensor.

Male Connectors and Adapters

- 68138 Male Connector and 116935 Male Connector: These connectors are essential for linking various components within the system. They ensure a secure and leak-proof connection between the viscosity sensor and other elements, such as pipes or hoses.

- 68139 Male Adapter Elbow: This component allows for a change in direction within the fluid pathway. It is used to connect straight sections of pipe to the sensor or other components at an angle, providing flexibility in system design.

Pipe Elbows and Tees

- 69318 Plain Street Pipe Elbow: Similar to the adapter elbow, this component facilitates directional changes in the piping system without the need for additional adapters. It is typically used for standard pipe connections.

- 3065117 Street Pipe Tee: This tee fitting allows for the division or merging of fluid flows within the system. It is crucial for integrating the viscosity sensor into an existing fluid line without interrupting the flow.

Flexible Hoses

- 3065134 Flexible Hose and AK400560SS Flexible Hose: These hoses provide the necessary flexibility to connect components that may not be in direct alignment. They are particularly useful for connecting the viscosity sensor to the system, accommodating any movement or vibration that may occur.

- AK601320SS Flexible Hose: Another variant of flexible hose, offering additional options for connection points within the system.

Adapters and Brackets

- 3054821 Female Adapter Elbow: This component is used to connect male-ended components to the system, providing a secure and angled connection point.

- 3065135 Valve Bracket: This bracket is designed to support and secure valves within the system, ensuring they remain in place and operate correctly.

Captive Washer Cap Screws

- 3008069 Captive Washer Cap Screw and 3052675 Captive Washer Cap Screw: These screws are used to secure various components within the system. The captive washer ensures that the screw does not strip the threads during installation or removal, maintaining the integrity of the connections.

Sensor

- 3066463 Viscosity Sensor: The core component of the kit, this sensor is responsible for measuring the viscosity of the fluid within the system. Accurate viscosity readings are critical for ensuring that the fluid meets the required specifications for optimal system performance.

Conclusion

The Cummins 3803240 plays a significant role in maintaining the optimal performance and efficiency of heavy-duty truck engines. By ensuring accurate viscosity measurements and facilitating real-time adjustments, this part contributes to improved engine lubrication, enhanced truck performance, and potential cost savings through better maintenance practices. Its integration with other systems and impact on fuel efficiency further underscore its importance in heavy-duty truck operations.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Male Connector | 1 | 68138 |

| Male Adapter Elbow | 1 | 68139 |

| Plain Street Pipe Elbow | 1 | 69318 |

| Male Connector | 1 | 116935 |

| Captive Washer Cap Screw | 2 | 3008069 |

| Captive Washer Cap Screw | 2 | 3052675 |

| Male Adapter Elbow | 1 | 3054821 |

| Street Pipe Tee | 1 | 3065117 |

| Flexible Hose | 1 | 3065134 |

| Valve Bracket | 1 | 3065135 |

| Viscosity Sensor | 1 | 3066463 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.