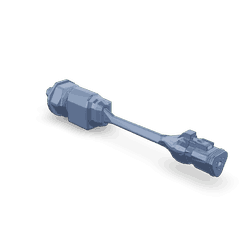

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4359494 Pressure Sensor is a critical component designed to monitor and report pressure levels within various systems of commercial trucks. It ensures accurate pressure readings, contributing to the efficient and safe operation of the vehicle. This sensor is integral to maintaining optimal performance by ensuring pressure levels are within required parameters 1.

Basic Concepts of Pressure Sensors

A pressure sensor measures pressure exerted by gases or liquids, converting it into an electrical signal for interpretation by the vehicle’s electronic systems. These sensors are essential in automotive systems for monitoring and controlling functions such as fuel injection, brake systems, and engine management 2.

Role of the 4359494 Pressure Sensor in Truck Operation

The Cummins 4359494 Pressure Sensor is crucial for the functioning of commercial trucks. It provides precise pressure readings that are integral to the operation of the truck’s systems, particularly within the engine management system. It helps regulate fuel injection and other critical functions by ensuring pressure levels are maintained within the desired range 3.

Key Features

The Cummins 4359494 Pressure Sensor is characterized by its robust design and high-quality materials, ensuring durability and reliability. Its technological specifications include high accuracy in pressure readings and compatibility with various truck systems, enhancing overall efficiency.

Benefits of Using the 4359494 Pressure Sensor

Incorporating the Cummins 4359494 Pressure Sensor into truck systems offers several advantages. It improves efficiency by ensuring systems operate within optimal pressure ranges, enhances safety by providing accurate pressure readings to prevent system failures, and improves overall performance by facilitating precise control over various truck functions.

Installation and Integration

Proper installation and integration of the Cummins 4359494 Pressure Sensor within a truck’s system require adherence to specific guidelines. This includes ensuring the sensor is correctly positioned and connected to the appropriate systems, and considering any prerequisites or system-specific requirements for seamless integration.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 4359494 Pressure Sensor, regular maintenance is recommended. This includes checking for signs of wear or damage and ensuring connections are secure. Common troubleshooting tips involve verifying the sensor’s readings against known values and checking for any obstructions or leaks in the system.

Cummins Corporation Overview

Cummins Inc. is a well-established corporation with a rich history in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is renowned for its commitment to quality and innovation, making it a trusted name in the industry. The Cummins 4359494 Pressure Sensor is part of its extensive product line, reflecting the company’s dedication to providing reliable and high-performance components for commercial trucks.

Role of Part 4359494 Pressure Sensor in Engine Systems

The integration of the 4359494 Pressure Sensor within engine systems is fundamental for maintaining optimal performance and efficiency. This sensor is strategically positioned to monitor and report pressure variations within the engine, providing essential data to the Engine Control Module (ECM).

Interaction with the Engine Control Module (ECM)

The 4359494 Pressure Sensor continuously feeds real-time pressure data to the ECM. The ECM utilizes this information to make precise adjustments to fuel injection, ignition timing, and other critical parameters. This ensures that the engine operates within its optimal range, enhancing both performance and fuel efficiency.

Contribution to Engine Performance

By accurately measuring pressure changes, the 4359494 Pressure Sensor allows the ECM to detect anomalies or inefficiencies in the engine’s operation. This early detection enables the ECM to implement corrective measures, such as adjusting the air-fuel mixture or modifying ignition timing, to maintain smooth and efficient engine operation.

Enhancing Diagnostic Capabilities

The data provided by the 4359494 Pressure Sensor is invaluable for diagnostic purposes. When the ECM receives abnormal pressure readings, it can trigger warning signals or store diagnostic trouble codes (DTCs). This facilitates quicker and more accurate troubleshooting, reducing downtime and repair costs.

Supporting Advanced Engine Features

In modern engine systems, the 4359494 Pressure Sensor plays a role in supporting advanced features such as variable valve timing and turbocharging. By providing precise pressure data, the sensor enables the ECM to optimize these features, resulting in improved engine responsiveness and power output.

Ensuring Compliance with Emission Standards

Accurate pressure monitoring is essential for meeting stringent emission standards. The 4359494 Pressure Sensor helps the ECM maintain the correct air-fuel ratio, reducing the emission of harmful pollutants. This not only ensures compliance with environmental regulations but also contributes to a cleaner and more sustainable operation.

Conclusion

The Cummins 4359494 Pressure Sensor is a vital component in the operation and maintenance of commercial trucks and their engine systems. Its accurate pressure readings and integration with the ECM ensure optimal engine performance, enhance diagnostic capabilities, support advanced engine features, and help maintain compliance with emission standards. Regular maintenance and proper installation are key to maximizing the benefits of this sensor.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3417238 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.