4384382

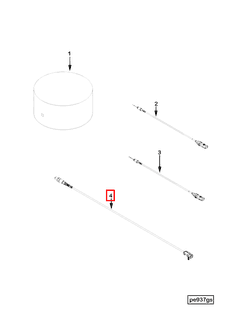

Oxygen Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4384382 Oxygen Sensor is designed to monitor oxygen levels in the exhaust gases of commercial trucks. It ensures the engine operates efficiently and meets emissions standards by providing real-time data to the engine management system, maintaining an optimal air-fuel ratio for fuel efficiency, emission reduction, and overall engine performance 1.

Basic Concepts of Oxygen Sensors

An oxygen sensor, or lambda sensor, measures the amount of unburned oxygen in exhaust gases using materials like zirconia or titania. These materials generate a voltage signal based on the difference in oxygen concentration between the exhaust gas and ambient air. The engine management system uses this signal to adjust the air-fuel mixture, ensuring efficient combustion 2.

Purpose of the Cummins 4384382 Oxygen Sensor

This Cummins part monitors the oxygen content in exhaust gases, providing feedback to the engine management system to adjust the air-fuel ratio. This adjustment maintains optimal combustion efficiency, enhances fuel economy, reduces emissions, and ensures smooth engine performance 3.

Key Features

The Cummins 4384382 Oxygen Sensor features a robust design and construction, utilizing high-quality materials for durability and reliability. It is engineered for compatibility with Cummins engines, offering precise oxygen level measurements. Advanced zirconia technology ensures accurate readings, and a robust housing withstands the harsh conditions of commercial truck operations 4.

Benefits

Using the Cummins 4384382 Oxygen Sensor offers several advantages, including improved fuel economy through optimal air-fuel ratio operation, reduced emissions for a better environmental footprint, enhanced engine performance and longevity by maintaining efficient combustion, and compliance with environmental regulations by ensuring the truck meets emissions standards 5.

Installation and Compatibility

Proper installation of the Cummins 4384382 Oxygen Sensor is crucial for its effective operation. It is designed for specific Cummins engine models, with installation guidelines provided for correct fitting and function. Attention to specific installation requirements ensures the sensor’s accuracy and durability 6.

Troubleshooting and Maintenance

Common issues with the Cummins 4384382 Oxygen Sensor can be addressed through troubleshooting and maintenance practices. Regular inspection and cleaning prevent buildup that may affect performance. Observing replacement intervals ensures the sensor continues to provide accurate readings, contributing to engine efficiency and emissions compliance 7.

Diagnostic Codes and Error Messages

Understanding common diagnostic trouble codes (DTCs) associated with oxygen sensor malfunctions is important for maintaining engine performance. These codes provide insights into sensor issues, allowing for appropriate corrective actions. Correctly interpreting error messages leads to timely sensor maintenance or replacement, ensuring the engine management system operates efficiently 8.

Environmental Impact

The Cummins 4384382 Oxygen Sensor reduces harmful emissions from commercial trucks by ensuring the engine operates at an optimal air-fuel ratio. This function supports environmental sustainability and compliance with emissions regulations, highlighting the sensor’s importance in modern engine management systems 9.

Cummins Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability in the automotive industry. The company’s product offerings include a wide range of engines and components designed to meet the demanding requirements of commercial and industrial applications 10.

Compatibility

The Cummins Oxygen Sensor 4384382 is designed to integrate with various Cummins engine models, ensuring optimal performance and efficiency. This sensor is engineered to fit the following engines:

15N CM2380 M104B

The 15N CM2380 M104B engine benefits from the precise monitoring provided by the 4384382 Oxygen Sensor, maintaining the engine’s air-fuel ratio for efficient combustion and reduced emissions.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is equipped with the 4384382 Oxygen Sensor to ensure optimal operation. This sensor is essential for the engine’s electronic control unit (ECU) to make real-time adjustments to the air-fuel mixture, enhancing performance and fuel economy.

Compatibility and Installation

The 4384382 Oxygen Sensor is designed for straightforward installation across these engine models. Cummins ensures the sensor’s design and connectors are compatible with the specified engines, allowing for easy replacement and maintenance. Technicians and mechanics can rely on this sensor to provide accurate readings, vital for the engine’s overall health and longevity.

Conclusion

The Cummins 4384382 Oxygen Sensor is a critical component for ensuring the efficient operation of commercial truck engines. By monitoring oxygen levels in exhaust gases and providing real-time data to the engine management system, it helps maintain an optimal air-fuel ratio. This not only enhances fuel economy and reduces emissions but also ensures compliance with environmental regulations. Proper installation, regular maintenance, and understanding diagnostic codes are essential for maximizing the benefits of this sensor, contributing to the overall performance and longevity of Cummins engines.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.