5415562

Oxygen Sensor

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5415562 Oxygen Sensor is designed to monitor oxygen levels in the exhaust gases of commercial trucks. This sensor provides essential data to the engine control unit (ECU), optimizing fuel injection and combustion processes. Its accurate readings contribute to efficient engine performance, reduced emissions, and compliance with environmental regulations 1.

Basic Concepts of Oxygen Sensors

An oxygen sensor, or lambda sensor, measures the amount of unburned oxygen in the exhaust gases emitted by an engine. It operates based on the principle of electrochemical cells, generating a voltage signal proportional to the oxygen concentration difference between the exhaust gas and the ambient air. This signal is sent to the ECU, which adjusts the air-fuel mixture to achieve optimal combustion efficiency 2.

Purpose of the Cummins 5415562 Oxygen Sensor

The Cummins 5415562 Oxygen Sensor is integral to the operation of a truck’s engine system. It monitors oxygen levels in the exhaust gases and provides feedback to the ECU. This feedback allows the ECU to make real-time adjustments to the fuel injection timing and quantity, ensuring the engine operates at peak efficiency. By maintaining the correct air-fuel ratio, the sensor helps to reduce emissions and improve fuel economy 3.

Key Features

The Cummins 5415562 Oxygen Sensor features a robust design and high-quality construction materials. It includes a zirconia-based sensing element, offering high sensitivity and durability. The sensor is designed to withstand the harsh conditions of commercial truck operations, including high temperatures and vibrations. Its compact design ensures easy installation and integration into the exhaust system.

Benefits of Using the Cummins 5415562 Oxygen Sensor

Incorporating the Cummins 5415562 Oxygen Sensor into a truck’s engine system offers several advantages. These include improved fuel efficiency through optimized air-fuel mixture, reduced emissions by ensuring complete combustion, enhanced engine performance due to precise control of the combustion process, and compliance with environmental regulations through accurate emission monitoring.

Installation and Compatibility

Proper installation of the Cummins 5415562 Oxygen Sensor is crucial for its effective operation. It should be installed in the exhaust system where it can accurately measure the oxygen levels in the exhaust gases. Specific requirements may include ensuring a secure fit and proper electrical connections. The sensor is compatible with various Cummins engines, ensuring seamless integration into the engine management system.

Troubleshooting and Maintenance

Common issues with oxygen sensors include contamination, electrical faults, and sensor degradation over time. Troubleshooting steps may involve checking for proper electrical connections, inspecting the sensor for physical damage, and using diagnostic tools to read error codes. Regular maintenance, such as cleaning the sensor and ensuring it is free from contaminants, can help maintain its performance and longevity.

Diagnostic Codes and Error Messages

Common diagnostic trouble codes (DTCs) related to oxygen sensor malfunctions include P0130 (O2 Sensor Circuit Malfunction) and P0135 (O2 Sensor Heater Circuit Malfunction). These codes indicate issues with the sensor’s electrical circuit or heating element. Interpreting these codes involves using a diagnostic scanner to read the ECU’s stored data and taking appropriate steps to address the underlying problem.

Performance Monitoring and Testing

Monitoring the performance of the Cummins 5415562 Oxygen Sensor can be achieved through various diagnostic tools and techniques. These may include using a multimeter to check the sensor’s voltage output, employing an oscilloscope to observe the sensor’s signal waveform, and utilizing engine diagnostic software to analyze the sensor’s data in real-time. Ensuring the sensor operates within specified parameters is crucial for maintaining engine efficiency and emissions compliance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products for various industries, including commercial trucks, where its engines and components are known for their reliability and performance. Cummins’ dedication to advancing technology and meeting customer needs underscores its reputation in the industry.

Cummins Oxygen Sensor 5415562 Compatibility

The Cummins Oxygen Sensor part number 5415562 is designed to be compatible with several engine models, ensuring optimal performance and efficiency. This sensor is integral to the engine’s emissions control system, monitoring the oxygen levels in the exhaust to help maintain the proper air-fuel ratio.

ISB6.7 G CM2180 B118 Engines

The 5415562 Oxygen Sensor is specifically engineered to fit seamlessly with the ISB6.7 G CM2180 B118 engines. These engines are known for their robust performance and reliability, making them a popular choice in various applications. The sensor’s design ensures it can withstand the high temperatures and pressures within these engines, providing accurate readings and contributing to the engine’s overall efficiency.

Grouping of Engines

When considering the compatibility of the 5415562 Oxygen Sensor, it is essential to recognize that it is part of a broader range of sensors designed for different engine models. This particular sensor is tailored for the ISB6.7 G CM2180 B118 engines, but Cummins offers a variety of sensors to fit their extensive lineup of engines. Each sensor is meticulously designed to meet the specific requirements of its corresponding engine model, ensuring compatibility and performance.

By using the 5415562 Oxygen Sensor in the ISB6.7 G CM2180 B118 engines, users can expect enhanced engine performance, improved fuel efficiency, and reduced emissions. This compatibility highlights Cummins’ commitment to providing high-quality, reliable parts that meet the needs of their customers.

Role of Part 5415562 Oxygen Sensor in Engine Systems

The part 5415562 Oxygen Sensor is integral to the efficient operation of several engine components. It works in conjunction with the aftertreatment device to ensure that emissions are kept within regulatory limits. By monitoring the oxygen levels in the exhaust gases, the sensor provides data that helps optimize the performance of the catalytic converter.

In the context of the catalytic converter, the oxygen sensor’s readings are vital for maintaining the correct air-fuel ratio. This ensures that the converter operates at peak efficiency, reducing harmful emissions and improving fuel economy.

The sensor also interfaces with the engine control module (ECM) to deliver real-time data. The ECM uses this information to make adjustments to the fuel injection timing and quantity, which is essential for maintaining engine performance and efficiency.

Overall, the part 5415562 Oxygen Sensor plays a significant role in the interplay between these components, ensuring that the engine runs smoothly, efficiently, and in compliance with environmental regulations.

Conclusion

The Cummins 5415562 Oxygen Sensor is a critical component in the operation of commercial truck engines. Its role in monitoring oxygen levels in the exhaust gases ensures optimal fuel injection and combustion processes, leading to efficient engine performance, reduced emissions, and compliance with environmental regulations. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

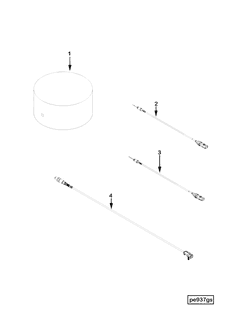

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.