Introduction

The Cummins 3914422 Tension Spring is a specialized component designed for use in commercial trucks. Its primary role is to maintain tension within various mechanical systems, ensuring smooth operation and efficiency. This spring is integral to the functionality of certain truck components, contributing to the overall performance and reliability of the vehicle 1.

Basic Concepts of Tension Springs

Tension springs are mechanical devices that store energy when stretched. They are designed to exert a force to return to their original length when the stretching force is removed. These springs are commonly used in various applications, including automotive systems, to maintain tension in components, absorb shocks, and ensure consistent operation of mechanical parts 3.

Purpose of the 3914422 Tension Spring in Truck Operation

The 3914422 Tension Spring plays a specific role in the operation of commercial trucks by maintaining the necessary tension in certain mechanical systems. It ensures that components remain securely in place and function as intended. This spring is particularly important in systems where consistent tension is required to prevent malfunction or failure, contributing to the truck’s overall efficiency and reliability 1.

Key Features

The Cummins 3914422 Tension Spring is characterized by several key features that enhance its performance. It is made from high-quality materials, ensuring durability and resistance to wear. The design specifications of this spring are tailored to meet the demanding requirements of commercial truck applications, providing reliable tension maintenance. Additionally, it may feature unique attributes such as corrosion resistance or specific load-bearing capabilities that further enhance its functionality 2.

Benefits of Using the 3914422 Tension Spring

Utilizing the Cummins 3914422 Tension Spring offers several advantages. It contributes to improved reliability by ensuring that mechanical systems operate within the intended tension parameters. This results in enhanced efficiency and performance of the truck. The spring’s design and material composition also contribute to its longevity, reducing the need for frequent replacements and maintenance 1.

Installation and Integration

Proper installation of the Cummins 3914422 Tension Spring is crucial for its effective operation. It should be integrated into the truck’s mechanical system according to manufacturer guidelines to ensure optimal performance. This may involve specific prerequisites or special considerations, such as ensuring the spring is correctly aligned and secured within the system 3.

Troubleshooting Common Issues

Common problems associated with tension springs can include loss of tension, corrosion, or physical damage. Addressing these issues may involve inspecting the spring for signs of wear or damage, ensuring it is correctly installed, and replacing it if necessary. Diagnostic tips and repair strategies can help maintain the spring’s functionality and extend its lifespan 2.

Maintenance Tips

Regular maintenance of the Cummins 3914422 Tension Spring is important to ensure its longevity and optimal performance. This includes routine inspections to check for signs of wear, corrosion, or damage. Care instructions may involve cleaning the spring and ensuring it remains free from debris that could affect its operation. Following these maintenance tips can help prevent issues and ensure the spring continues to function effectively 1.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong history of innovation and quality in the automotive industry. The company is known for its commitment to producing reliable and efficient components, including the Cummins 3914422 Tension Spring. Cummins’ expertise in engine and component design ensures that their products meet the high standards required for commercial truck applications 2.

Role of Part 3914422 Tension Spring in Engine Systems

The 3914422 tension spring is integral to the functionality of several engine components, ensuring smooth operation and precise control.

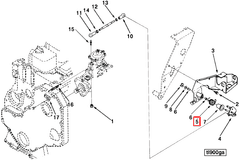

Throttle Control Bracket

In the throttle control bracket, the 3914422 tension spring maintains the necessary tension to keep the throttle plate in the correct position. This ensures that the airflow into the engine is regulated accurately, which is essential for maintaining the desired engine speed and power output. The spring’s role here is to provide consistent pressure, allowing for responsive throttle adjustments and preventing any unwanted fluctuations in engine performance 3.

Conclusion

The Cummins 3914422 Tension Spring is a vital component in the operation of commercial trucks and engine systems. Its role in maintaining tension within mechanical systems ensures smooth operation, efficiency, and reliability. Proper installation, regular maintenance, and understanding its key features and benefits are essential for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.