This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3918455 Torsion Spring is a specialized component designed for use in commercial trucks. Its primary purpose is to provide the necessary tension and stability within the truck’s mechanical systems, ensuring smooth and efficient operation. This torsion spring is integral to the functionality of various truck components, contributing to the overall performance and reliability of the vehicle.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational force. They operate by twisting along their axis when a force is applied, and they return to their original position once the force is removed. These springs are commonly used in a variety of applications, including automotive systems, to provide tension, balance, and control within mechanical assemblies. Their ability to withstand repeated cycles of stress and strain makes them ideal for use in demanding environments 1.

Purpose of the 3918455 Torsion Spring in Truck Operation

The Cummins 3918455 Torsion Spring plays a specific role in the operation of commercial trucks by maintaining tension and stability within the truck’s mechanical systems. It is often used in components such as the suspension system, where it helps to absorb shocks and vibrations, ensuring a smoother ride and reducing wear on other parts. Additionally, it may be employed in the engine compartment to secure components and maintain proper alignment, contributing to the overall efficiency and reliability of the truck.

Key Features

The Cummins 3918455 Torsion Spring is characterized by several key features that enhance its performance and durability. It is typically made from high-quality steel, which provides the necessary strength and resilience to withstand the rigors of commercial truck operation. The spring is designed with precise specifications to ensure it fits correctly within the truck’s mechanical systems and performs its intended function effectively. Additionally, it may feature unique attributes such as a corrosion-resistant coating to protect against environmental factors and extend its service life 2.

Benefits

The Cummins 3918455 Torsion Spring offers several advantages that contribute to the mechanical efficiency and reliability of commercial trucks. By providing consistent tension and stability, it helps to reduce wear on other components, leading to longer service intervals and lower maintenance costs. Its robust construction ensures it can withstand the demanding conditions of truck operation, enhancing the overall performance and durability of the vehicle. Furthermore, the spring’s precise design allows for optimal integration within the truck’s mechanical systems, ensuring smooth and efficient operation 3.

Installation and Integration

Proper installation and integration of the Cummins 3918455 Torsion Spring are crucial for ensuring optimal performance and longevity. Before installation, it is important to verify that the spring is the correct size and type for the specific application. The installation process should follow manufacturer guidelines to ensure the spring is securely positioned and properly tensioned. Any prerequisites, such as cleaning the installation area or lubricating the spring, should be observed to prevent damage and ensure smooth operation. Regular inspections and maintenance checks are recommended to verify that the spring remains in good condition and continues to function as intended.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 3918455 Torsion Spring, regular maintenance and troubleshooting are necessary. Common issues may include signs of wear, such as corrosion or deformation, which can affect the spring’s performance. Regular inspections should be conducted to identify any signs of damage or failure, and the spring should be replaced if necessary. Maintenance tips include keeping the spring clean and free of debris, ensuring proper lubrication, and verifying that it remains correctly tensioned. By following these guidelines, the spring can continue to provide reliable performance and contribute to the overall efficiency of the truck.

Safety Considerations

When handling, installing, or maintaining the Cummins 3918455 Torsion Spring, it is important to observe several safety guidelines to ensure the safety of personnel and the proper functioning of the truck. Always wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential injuries. Ensure that the spring is handled carefully to avoid sudden releases of stored energy, which can cause injury. Follow manufacturer guidelines for installation and maintenance to prevent damage to the spring or other components. By adhering to these safety considerations, the risk of accidents and equipment failure can be minimized.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the diverse needs of its customers, from heavy-duty trucks to off-highway equipment. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry, providing solutions that enhance the performance and efficiency of commercial vehicles.

Cummins Engine Compatibility with Torsion Spring Part 3918455

The Torsion Spring part 3918455, manufactured by Cummins, is a critical component in various engine models. This part is designed to provide essential functionality across a range of Cummins engines, ensuring optimal performance and reliability.

Engine Models

- 6B5.9: The Torsion Spring part 3918455 is integral to the 6B5.9 engine, where it plays a pivotal role in maintaining the engine’s operational integrity. Its design ensures that the spring can withstand the rigors of engine operation, providing consistent performance over time.

Application and Functionality

In the 6B5.9 engine, the torsion spring is utilized to maintain tension and alignment within the engine’s components. This ensures that parts such as valves and pistons operate smoothly, reducing wear and tear and enhancing the engine’s overall lifespan. The spring’s ability to absorb and distribute stress effectively is crucial for the engine’s performance and durability.

Installation and Maintenance

Proper installation of the Torsion Spring part 3918455 is essential for the engine’s functionality. Technicians should follow Cummins’ guidelines for installation to ensure that the spring is correctly positioned and secured. Regular maintenance checks should be conducted to verify that the spring remains in good condition, free from damage or excessive wear, which could compromise engine performance.

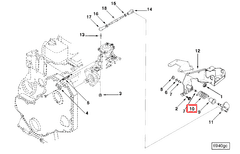

Role of Part 3918455 Torsion Spring in Engine Systems

The 3918455 torsion spring is a vital component in the operation of several engine systems, particularly those involving the throttle control mechanism. This spring is instrumental in maintaining the proper tension and balance required for the efficient functioning of the throttle control and its associated bracket.

Throttle Control Mechanism

In the throttle control system, the 3918455 torsion spring works in conjunction with the throttle control bracket to regulate the airflow into the engine. The spring’s primary function is to provide the necessary resistance that allows for precise control of the throttle position. This is essential for maintaining the desired engine speed and power output under varying driving conditions.

Interaction with Throttle Control Bracket

The throttle control bracket serves as the mounting point for the throttle control and is directly influenced by the tension provided by the 3918455 torsion spring. The spring ensures that the bracket remains in the correct position, allowing for smooth and responsive throttle operation. This interaction is key to preventing any unwanted movement or vibration that could affect the throttle’s performance.

Ensuring Smooth Operation

The 3918455 torsion spring’s role extends beyond just providing tension. It also helps in dampening any vibrations that might be transmitted through the throttle control system. This is particularly important in high-performance engines where even minor vibrations can lead to decreased efficiency and increased wear on other components.

Integration with Engine Systems

When integrated into the engine system, the 3918455 torsion spring contributes to the overall stability and reliability of the throttle control mechanism. Its proper function ensures that the engine responds accurately to driver inputs, which is essential for both performance and safety.

Conclusion

The Cummins 3918455 Torsion Spring is a critical component in the operation of commercial trucks and Cummins engines. Its role in maintaining tension, stability, and alignment within various mechanical systems ensures smooth and efficient operation. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the performance and longevity of this part. By understanding the key features, benefits, and applications of the 3918455 torsion spring, technicians and operators can ensure optimal engine and vehicle performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.