3678610

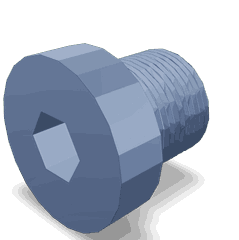

Threaded Plug

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Threaded Plug 3678610 is a component designed for use in commercial truck operations. It serves a specific function within the truck’s system, primarily focused on sealing openings and preventing fluid leaks. This plug is integral to maintaining the integrity of the truck’s fluid systems, ensuring efficient operation and longevity of the vehicle.

Basic Concepts of Threaded Plugs

Threaded plugs are mechanical components used to seal openings in various systems. They consist of a cylindrical body with threads that allow them to be screwed into corresponding threaded holes. In automotive and industrial settings, threaded plugs are employed to prevent the escape of fluids, gases, or particulates from systems where containment is necessary. They are commonly found in engine blocks, transmission cases, and hydraulic systems 1.

Purpose of Cummins Threaded Plug 3678610

The Cummins Threaded Plug 3678610 is specifically designed to seal openings in truck systems, preventing fluid leaks that could lead to system failure or contamination. By securely fitting into threaded holes, it creates a barrier that maintains the pressure and integrity of the fluid within the system. This plug plays a role in ensuring that the truck operates efficiently and safely by preventing unwanted fluid loss.

Key Features

The Cummins Threaded Plug 3678610 is constructed with features that enhance its performance and durability. It is made from materials that resist corrosion and wear, ensuring longevity in harsh operating conditions. The plug features a specific thread type that ensures a secure fit in the corresponding holes, and its design specifications are tailored to meet the demands of commercial truck applications.

Benefits

Using the Cummins Threaded Plug 3678610 offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system pressure and preventing leaks. The plug’s resistance to corrosion and wear contributes to its longevity, reducing the need for frequent replacements. Additionally, its design ensures a secure fit, which is vital for the reliable operation of the truck’s fluid systems.

Installation Process

Proper installation of the Cummins Threaded Plug 3678610 involves several steps to ensure a secure and effective seal. It is important to clean the threaded hole to remove any debris or old sealant. The plug should be screwed in by hand until it contacts the surface, followed by the use of a torque wrench to achieve the manufacturer’s specified torque setting. Care should be taken to avoid over-tightening, which could damage the threads or the plug itself.

Troubleshooting and Maintenance

Common issues with threaded plugs include leaks due to improper installation or damage to the plug or threads. Regular inspection for signs of wear or corrosion is recommended. If a leak is detected, the plug should be removed, the threads inspected for damage, and a new plug installed if necessary. Maintenance practices such as keeping the area around the plug clean and free of debris can help ensure optimal performance.

Common Applications

The Cummins Threaded Plug 3678610 is utilized in various truck models and systems where sealing openings is necessary to prevent fluid leaks. It is commonly found in engine blocks, transmission cases, and other systems where fluid containment is critical for the operation and longevity of the truck.

Safety Considerations

When handling and installing the Cummins Threaded Plug 3678610, it is important to observe safety guidelines to ensure user and equipment safety. This includes wearing appropriate personal protective equipment, ensuring the truck is properly supported and the engine is off before beginning work, and following all manufacturer recommendations for torque settings and installation procedures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses 2.

Threaded Plug 3678610 Compatibility with Cummins Engines

The threaded plug 3678610, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engine models. This part is essential for sealing and securing various points in the engine’s system, ensuring optimal performance and reliability.

ISB and ISBE Series

The threaded plug 3678610 is compatible with several models in the ISB and ISBE series:

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

These engines are known for their robust performance and are widely used in various applications, from heavy-duty trucks to industrial machinery.

ISC and ISL Series

The threaded plug 3678610 also fits the following ISC and ISL series engines:

- ISC CM554

- ISC CM850

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

These engines are designed for applications requiring high power and durability, often found in construction and agricultural equipment.

ISM and ISF Series

The threaded plug 3678610 is also suitable for the following ISM and ISF series engines:

- ISM CM876

- ISF2.8 CM2220 F129

These engines are typically used in medium-duty trucks and other commercial vehicles, providing reliable performance and efficiency.

ISX Series

The threaded plug 3678610 fits the following ISX series engines:

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

These high-performance engines are often used in heavy-duty trucks and other demanding applications, requiring components that can withstand extreme conditions.

B Series

The threaded plug 3678610 is also compatible with the following B series engines:

- B4.5 RGT

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

These engines are commonly used in a variety of applications, from construction equipment to agricultural machinery, providing dependable power and efficiency.

Role of Part 3678610 Threaded Plug in Engine Systems

The part 3678610 Threaded Plug is an essential component in various engine systems, ensuring the integrity and efficiency of the engine’s operation. Its applications span across multiple critical areas, including but not limited to:

-

Catalytic Converter: The threaded plug is utilized to seal openings or ports within the catalytic converter, preventing exhaust leaks and ensuring optimal performance of the emission control system.

-

Compressor Housing: In the compressor housing of a turbocharger, the threaded plug is employed to seal off unused ports or passages, maintaining the efficiency of the compressed air flow and preventing leaks.

-

Cylinder Block and Cylinder Head: Within the cylinder block and cylinder head assemblies, the threaded plug is used to seal off coolant or oil passages that are not in use, ensuring that the fluid systems operate without contamination or loss of pressure.

-

Electronic Control Pressure Valve: The threaded plug may be used in the electronic control pressure valve system to seal off ports that are not active, ensuring that the valve operates within the designed pressure parameters.

-

Engine Control Module (ECM): Although not directly interfacing with the ECM, the threaded plug can be part of the sensor or actuator housings connected to the ECM, ensuring accurate readings and reliable operation.

-

Engineering Cooler Leak Test Kit: During leak testing of the engineering cooler, the threaded plug is used to seal specific points, allowing for precise testing and identification of leaks within the cooling system.

-

Exhaust Cooler Water Outlet Tube: In the exhaust cooler system, the threaded plug seals the water outlet tube to prevent coolant loss and maintain the efficiency of the cooling process.

-

Fuel System Components: Including the fuel drain tube, fuel filter head, and fuel manifold kit, the threaded plug ensures that fuel lines and passages are sealed correctly, preventing fuel leaks and maintaining system pressure.

-

Lubricating Oil Systems: In the lubricating oil cooler module and lubricating oil filter head, the threaded plug is used to seal off unused oil passages, ensuring that the lubrication system functions efficiently without contamination.

-

Turbocharger and Turbocharger Plumbing: The threaded plug is vital in sealing various ports within the turbocharger and its plumbing, ensuring that the compressed air system remains leak-free and operates at peak efficiency.

-

Water Pump: Within the water pump assembly, the threaded plug is used to seal off passages that are not in use, ensuring that the coolant flow is directed correctly and efficiently throughout the engine.

The threaded plug’s role in these systems underscores its importance in maintaining the engine’s operational integrity, efficiency, and safety.

Conclusion

The Cummins Threaded Plug 3678610 is a critical component in commercial truck operations, designed to seal openings and prevent fluid leaks within the truck’s systems. Its compatibility with a wide range of Cummins engine models, coupled with its robust construction and key features, ensures efficient and reliable operation of the truck’s fluid systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3678603 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.