3678603

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3678603 O Ring Seal is a critical component designed for use in commercial trucks. Its primary function is to provide a reliable seal in various systems and components within these vehicles. This seal is integral to maintaining the integrity of fluid systems, ensuring that liquids and gases remain contained within their designated pathways.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket consisting of a toroidal (doughnut-shaped) piece of elastomeric material. It is designed to create a seal between two or more parts. The construction of an O Ring involves a single piece of material, which is typically made from rubber or a synthetic elastomer. These materials are chosen for their flexibility, resilience, and ability to conform to the surfaces they seal against. The O Ring functions by being compressed into a groove, where it forms a barrier that prevents leakage of fluids or gases 1.

Role of the Cummins 3678603 O Ring Seal in Truck Operation

The Cummins 3678603 O Ring Seal plays a specific role in the operation of commercial trucks. It is associated with systems that require a dependable seal to function correctly. This includes fuel systems, hydraulic systems, and other fluid transfer mechanisms within the truck. By ensuring that these systems remain sealed, the O Ring contributes to the efficient operation of the truck, preventing leaks that could lead to performance issues or safety hazards.

Key Features

The Cummins 3678603 O Ring Seal is characterized by several key features that enhance its performance and durability. Its design is tailored to fit specific grooves within the truck’s components, ensuring a snug fit. The material properties of the O Ring, typically a durable elastomer, allow it to withstand the pressures and temperatures encountered in truck operations. Additionally, any unique characteristics, such as resistance to certain chemicals or oils, further contribute to its effectiveness in sealing applications.

Benefits

The use of the Cummins 3678603 O Ring Seal offers several benefits. It provides improved sealing efficiency, which is crucial for the proper functioning of the truck’s systems. The seal’s longevity ensures that it can withstand the rigors of commercial truck use over an extended period. Furthermore, the reliability of the seal contributes to the overall dependability of the truck’s systems, reducing the likelihood of unexpected failures or maintenance needs.

Troubleshooting and Maintenance

Identifying common issues related to O Ring Seals, such as leaks or degradation, is important for maintaining the effectiveness of the Cummins 3678603 O Ring Seal. Troubleshooting steps may include inspecting the seal for signs of wear, checking the grooves for proper fit, and ensuring that the seal is made from the correct material for the application. Regular maintenance practices, such as replacing the seal at recommended intervals or when signs of wear are detected, can help ensure the longevity and effectiveness of the O Ring Seal.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins plays a significant role in the manufacturing of automotive components. The company’s dedication to excellence is evident in its products, which are designed to meet the demanding requirements of commercial and industrial applications.

Cummins Engine Part 3678603 O Ring Seal Compatibility

The O Ring Seal part number 3678603, manufactured by Cummins, is a critical component designed to ensure a secure seal in various engine applications. This seal is integral to maintaining the integrity of the engine’s systems by preventing leaks and ensuring that fluids remain within designated pathways. Below is a detailed breakdown of the engines with which this O Ring Seal is compatible:

Cummins M Series Engines

- 15N CM2380 M104B

- 4B3.9

- 6B5.9

- 6C8.3

- B4.5 CM2350 B129B

- B4.5 RGT

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

- D4.0 CM2620 D103B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

Cummins ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

The O Ring Seal part number 3678603 is meticulously engineered to fit seamlessly within the specified engine models, ensuring optimal performance and reliability. This seal is particularly important in maintaining the pressure and fluid dynamics within the engine, contributing to the overall efficiency and longevity of the engine systems.

Role of Part 3678603 O Ring Seal in Engine Systems

The Part 3678603 O Ring Seal is instrumental in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

Integration with Engine Components

-

Adapter Connection: The O Ring Seal is utilized in adapter connections to prevent leaks between mating surfaces, ensuring a secure and leak-free interface.

-

Aftercooler Water Plumbing: In the aftercooler water plumbing system, the O Ring Seal ensures that coolant flows without any leakage, maintaining optimal cooling efficiency.

-

Cylinder Block Hardware Kit: Within the cylinder block hardware kit, the O Ring Seal is employed to seal connections and passages, preventing oil or coolant leaks that could compromise engine performance.

-

Engine Instrument Panel: Although indirectly related, the O Ring Seal may be used in the connections of the engine instrument panel to ensure accurate readings by preventing fluid leaks that could affect sensor accuracy.

-

Engine Monitoring System: Seals in the engine monitoring system help maintain the integrity of fluid lines, ensuring that the system operates within specified parameters without contamination or loss of fluids.

-

Engine Speed Sensor: The O Ring Seal may be used in the mounting or connection points of the engine speed sensor to ensure a stable and leak-free installation.

-

Fan Drive: In the fan drive system, the O Ring Seal helps in sealing connections, ensuring efficient operation and preventing coolant or oil leaks.

-

Female Connector: The O Ring Seal is often used in female connectors across various systems to ensure a tight seal, preventing fluid escape.

-

Filter Support: Within filter support systems, the O Ring Seal ensures that filters are securely mounted and that there are no leaks around the filter housing.

-

Fuel Plumbing: The O Ring Seal is vital in fuel plumbing to ensure that fuel lines are sealed properly, preventing any fuel leaks that could pose a safety hazard.

-

Heat Exchanger: In heat exchangers, the O Ring Seal is used to maintain the separation of fluids, ensuring efficient heat transfer without cross-contamination.

-

Intercooler: The O Ring Seal is employed in intercooler systems to seal connections, ensuring that the cooling process is efficient and that there are no leaks in the system.

-

Kit: Various kits may include the O Ring Seal to ensure that all connections within the kit are sealed properly during installation.

-

ISM Certification: While not a physical component, ensuring that all seals, including the O Ring Seal, are correctly installed is part of meeting ISM certification standards.

-

Male Union: The O Ring Seal is used in male unions to create a secure connection, preventing leaks in fluid systems.

-

Mounting Kit: In mounting kits, the O Ring Seal ensures that components are securely mounted and that there are no fluid leaks at connection points.

-

Oil Pressure Assembly Lubricating: The O Ring Seal is crucial in the oil pressure assembly to ensure that oil lines are sealed, maintaining proper lubrication and pressure within the engine.

-

Oil Replenishing System: In the oil replenishing system, the O Ring Seal ensures that oil lines are sealed, preventing leaks and ensuring the system functions correctly.

-

Product Installation Package: Many installation packages include the O Ring Seal to ensure that all components are properly sealed during installation.

-

Rear Gear Train Accessory Drive: The O Ring Seal is used in the rear gear train accessory drive to seal connections, ensuring efficient operation and preventing oil leaks.

-

Set: Various sets may include the O Ring Seal to ensure that all components within the set are properly sealed.

-

Upper Gasket: While not directly related, the O Ring Seal may be used in conjunction with upper gaskets to ensure a complete seal in various engine components.

-

Thermostat Housing: The O Ring Seal is used in thermostat housing to ensure that coolant is contained within the system, maintaining proper engine temperature.

-

Tube Connector: In tube connectors across various systems, the O Ring Seal ensures a tight seal, preventing fluid leaks.

-

Turbocharger Arrangement: The O Ring Seal is used in turbocharger arrangements to seal connections, ensuring efficient operation and preventing oil leaks.

-

Upper Engine Gasket Set: Although primarily gaskets, the O Ring Seal may be used in conjunction with upper engine gasket sets to ensure a complete seal in various engine components.

-

Zinc Electrode Plug: The O Ring Seal may be used in the installation of zinc electrode plugs to ensure a secure and leak-free connection.

Conclusion

The Cummins 3678603 O Ring Seal is a vital component in the operation and maintenance of commercial trucks and engines. Its design and material properties ensure reliable sealing across various systems, contributing to the efficiency, safety, and longevity of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Limpert, Rudolf. Brake Design and Safety, Third Edition. SAE International, 2011.

↩

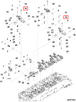

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Sealing Washer | 2 | 4944257 |

| Split Ring Seal | 1 | 3758848 |

| Retaining Ring | 4 | 3762259 |

| Hexagon Flange Head Cap Screw | 1 | 3527184 |

| Drive Screw | 2 | 3519163 |

| Clamping Plate | 2 | 2839879 |

| Hexagon Head Set Screw | 5 | 2840364 |

| Hexagon Head Set Screw | 4 | 2840781 |

| Turbocharger Bearing | 2 | 3503100 |

| Plain Washer | 3 | 3504967 |

| Turbocharger Heat Shield | 1 | 3519302 |

| Retaining Ring | 1 | 3527566 |

| O Ring Seal | 1 | 3528933 |

| Retaining Ring | 1 | 3531238 |

| Mounting Spacer | 3 | 3532195 |

| Mounting Spacer | 1 | 3532196 |

| Thrust Collar | 1 | 3532217 |

| Retaining Ring | 1 | 3533163 |

| Hexagon Head Set Screw | 2 | 3534291 |

| Adapter Gasket | 1 | 3535001 |

| Turbocharger Thrust Bearing | 1 | 3595651 |

| Lock Nut | 1 | 3596402 |

| Male Connector | 1 | 3922790 |

| O Ring Seal | 2 | 3922794 |

| Compressor Housing | 1 | 4047764 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.