4331250

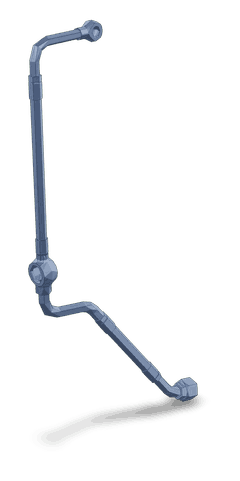

Tur Coolant Supply Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tur Coolant Supply Tube, manufactured by Cummins, is a vital component in the cooling systems of heavy-duty truck engines. Cummins, a prominent name in the automotive and heavy-duty truck industries, designs this part to ensure efficient engine cooling, which is essential for maintaining optimal engine performance and longevity 2.

Function and Operation

The Tur Coolant Supply Tube operates within the engine cooling system by directing coolant flow to critical engine components. It facilitates the circulation of coolant from the radiator to the engine block and other areas requiring cooling. This ensures that the engine maintains an appropriate operating temperature, which is crucial for its efficient and reliable operation 1.

Purpose of the Tur Coolant Supply Tube

The specific role of the Tur Coolant Supply Tube is to maintain engine temperature by ensuring that coolant is evenly distributed to areas prone to overheating. This helps in preventing engine damage due to excessive heat and ensures that the cooling system functions efficiently.

Key Features

The Tur Coolant Supply Tube is designed with several features that enhance its performance. It is constructed from durable materials that can withstand high temperatures and pressures within the engine cooling system. The tube includes precise connection types that ensure a secure fit and reliable coolant flow. Additionally, its design may incorporate features that reduce the risk of leaks and improve overall system efficiency.

Benefits

The advantages provided by the Tur Coolant Supply Tube include improved coolant distribution, which leads to more effective engine cooling. This enhances engine protection by preventing overheating and reduces the risk of engine damage. Furthermore, the tube’s reliable design contributes to increased system reliability and longevity.

Installation and Compatibility

Proper installation of the Tur Coolant Supply Tube is important to ensure it functions correctly within the engine cooling system. Specific requirements may include ensuring the tube is correctly aligned and securely connected to avoid leaks. Compatibility with various engine models should be considered to ensure optimal performance and integration within the existing cooling system.

Maintenance and Troubleshooting

Routine maintenance practices for the Tur Coolant Supply Tube include regular inspections for signs of wear, leaks, or corrosion. Ensuring the connections are tight and the tube is free from obstructions can help maintain its performance. Troubleshooting common issues such as leaks or blockages involves identifying the source of the problem and taking corrective action, which may include repairs or replacement of the tube.

Common Failure Modes

Typical failure modes associated with the Tur Coolant Supply Tube include leaks, blockages, and corrosion. These issues can impact engine performance by disrupting coolant flow, leading to overheating and potential engine damage. Regular maintenance and prompt addressing of any issues can help mitigate these failure modes.

Replacement and Upgrades

When a Tur Coolant Supply Tube shows signs of failure or wear, it should be replaced to maintain engine cooling efficiency. Upgrades may be available that offer improved materials or designs, enhancing performance or durability. It is important to follow manufacturer guidelines for replacement to ensure compatibility and optimal function.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its high-quality engine and component offerings. With a rich history of innovation and a strong reputation for reliability, Cummins continues to provide solutions that meet the demanding requirements of heavy-duty applications 2.

Compatibility with Cummins Engines

The Tur Coolant Supply Tube, identified by the part number 4331250, is a critical component in the cooling system of several Cummins engines. This part is designed to ensure efficient coolant flow, which is essential for maintaining optimal engine temperature and performance.

ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines are part of Cummins’ heavy-duty lineup, known for their robust performance and reliability. The Tur Coolant Supply Tube is integral to these engines, facilitating the transfer of coolant from the radiator to the engine block. This ensures that the engine operates within its optimal temperature range, enhancing longevity and efficiency.

QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine, another member of Cummins’ lineup, also benefits from the Tur Coolant Supply Tube. This part is essential for maintaining the engine’s thermal balance, especially under heavy-duty conditions. The efficient flow of coolant helps in dissipating heat effectively, preventing overheating and potential engine damage.

Grouping of Engines

The ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250 engines can be grouped together due to their similar design and performance characteristics. Both engines are designed for heavy-duty applications and share many components, including the Tur Coolant Supply Tube. This commonality allows for easier maintenance and part compatibility across these models.

The QSX11.9 CM2250 ECF, while part of the same family, is designed for specific applications that require a balance of power and efficiency. The Tur Coolant Supply Tube plays a crucial role in ensuring that this engine operates smoothly and reliably under various conditions.

Role of Part 4331250 Tur Coolant Supply Tube in Engine Systems

The Part 4331250 Tur Coolant Supply Tube is an essential component in the efficient operation of engine systems, particularly in relation to the turbocharger and overall plumbing setup.

Turbocharger Integration

In turbocharged engines, the turbocharger plays a significant role in enhancing performance by compressing the intake air, allowing more fuel to be burned and thus producing more power. The Tur Coolant Supply Tube is responsible for delivering coolant to the turbocharger. This is important for several reasons:

-

Heat Management: The turbocharger operates at extremely high temperatures. The coolant supplied by the Tur Coolant Supply Tube helps in dissipating this heat, preventing overheating and potential damage to the turbocharger.

-

Lubrication: In some designs, the coolant also acts as a lubricant for the turbocharger’s internal components, reducing wear and tear.

-

Efficiency: By maintaining optimal operating temperatures, the Tur Coolant Supply Tube ensures that the turbocharger functions efficiently, contributing to the overall performance and longevity of the engine.

Plumbing System Coordination

The Tur Coolant Supply Tube is a key element in the engine’s plumbing system. It connects various components to ensure a seamless flow of coolant throughout the system:

-

Coolant Circulation: The tube facilitates the circulation of coolant from the engine’s cooling system to the turbocharger and back. This continuous flow is vital for maintaining consistent temperatures across all engine components.

-

Pressure Regulation: Proper coolant flow through the Tur Coolant Supply Tube helps in regulating pressure within the cooling system, preventing issues such as coolant leaks or system failures.

-

System Integrity: The tube’s design and placement are critical for the integrity of the cooling system. It ensures that coolant reaches all necessary points without obstruction, supporting the engine’s thermal management.

Conclusion

In summary, the Part 4331250 Tur Coolant Supply Tube is integral to the turbocharger’s operation and the engine’s plumbing system. Its role in heat management, lubrication, and coolant circulation underscores its importance in maintaining engine efficiency and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.