This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Coolant Supply Tube, identified by part number 2865051, is a component manufactured by Cummins. This tube is integral to the engine cooling system, facilitating the efficient operation of the turbocharger in heavy-duty trucks. Cummins, a well-established name in the automotive industry, is recognized for its high-quality diesel engines and components, including this cooling system part.

Basic Concepts

To understand the role of the Turbocharger Coolant Supply Tube, it is important to grasp the fundamental principles behind turbochargers. Turbochargers increase an engine’s power output by compressing the air entering the combustion chamber, allowing for more fuel to be burned and thus generating more power. In heavy-duty trucks, where performance and efficiency are paramount, cooling systems are necessary to manage the high temperatures generated by turbochargers. The Turbocharger Coolant Supply Tube is a key component in this system, ensuring that coolant is delivered to the turbocharger to maintain optimal operating temperatures 1.

Function and Operation

The Turbocharger Coolant Supply Tube plays a role in the engine cooling system by facilitating the flow of coolant to the turbocharger. This process helps in dissipating heat, preventing overheating, and ensuring that the turbocharger operates within its designed temperature range. By maintaining the turbocharger at an optimal temperature, the tube contributes to the overall efficiency and reliability of the engine 2.

Key Features

The 2865051 Turbocharger Coolant Supply Tube is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and high temperatures. The tube’s design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, it may incorporate unique attributes such as reinforced sections to withstand the pressures and temperatures encountered in heavy-duty applications.

Benefits

The Turbocharger Coolant Supply Tube offers several advantages. By ensuring that the turbocharger remains cool, it helps improve engine efficiency and reduces thermal stress on the turbocharger components. This results in enhanced overall performance of the truck, including better fuel efficiency and increased power output. The tube’s durable construction also contributes to the longevity of the cooling system, reducing the need for frequent replacements 3.

Installation and Compatibility

Proper installation of the Turbocharger Coolant Supply Tube is important to ensure its effectiveness and compatibility with various truck models and engine types. Installation guidelines typically include steps to verify that all connections are secure and that the tube is correctly positioned within the engine bay. Ensuring compatibility with the specific truck model and engine type is also important to maintain the efficiency and reliability of the cooling system.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the Turbocharger Coolant Supply Tube. This includes periodic inspections for signs of wear, corrosion, or leaks. Common issues that may arise include blockages or restrictions in the coolant flow, which can be addressed by cleaning or replacing the tube if necessary. Troubleshooting steps may involve checking the connections and ensuring that the coolant system is functioning correctly.

Performance Impact

The Turbocharger Coolant Supply Tube affects the performance of the truck by contributing to the efficient operation of the turbocharger. This results in improved fuel efficiency, as the engine can operate more effectively under various conditions. Additionally, by maintaining optimal turbocharger temperatures, the tube helps in achieving consistent power output and enhances the durability of the engine under demanding operating conditions 4.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its diesel engines and related components. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance engines. The company’s product range includes a variety of components designed to enhance the efficiency and durability of heavy-duty trucks, reflecting Cummins’ commitment to excellence in the automotive sector.

Compatibility with Cummins Engines

The Turbocharger Coolant Supply Tube (part 2865051) is compatible with several Cummins engine models, including the ISX12 CM2350 X102, ISX12/ISX11.9 CM2250, and QSX11.9 CM2250 ECF. These engines are part of Cummins’ lineup of high-performance, heavy-duty diesel engines, often used in commercial and industrial applications. The part ensures that the turbocharger operates within its optimal temperature range, enhancing efficiency and reducing wear.

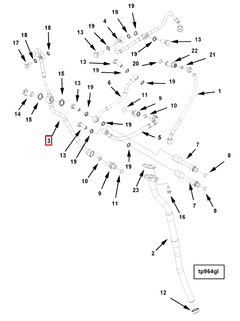

Role in Turbocharger Plumbing

The Turbocharger Coolant Supply Tube is an essential component in the turbocharger plumbing system. Its primary function is to facilitate the flow of coolant to the turbocharger, ensuring optimal thermal management and performance. The tube is integrated into the coolant flow pathway, connecting the engine’s coolant system to the turbocharger. This ensures that coolant is efficiently directed to the turbocharger housing, where it absorbs excess heat generated during operation.

Conclusion

The Turbocharger Coolant Supply Tube (part 2865051) is a critical component in the cooling system of Cummins engines, ensuring efficient operation and longevity of the turbocharger. Its role in maintaining optimal turbocharger temperatures contributes to the overall performance and reliability of the engine, making it an essential part for heavy-duty truck applications.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Department of Energy, Department of Energy Fundamentals Handbook (Department of Energy, 2015).

↩ -

Konrad Reif, Gasoline Engine Management Systems and Components (Springer Vieweg, 2015).

↩ -

Hannes Hick, Klaus Kupper, and Helfried Sorger, Systems Engineering for Automotive Powertrain Development (Springer, 2021).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.