This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Bearing Housing, specifically Part #3522740 by Cummins, is a vital component in heavy-duty truck engines. Cummins, a renowned manufacturer in the automotive industry, designs this part to enhance engine performance and efficiency. This housing plays a significant role in the turbocharger system, contributing to the overall functionality and reliability of truck engines.

Basic Concepts of Turbocharger Bearing Housing

Turbocharger bearing housings are integral to the operation of turbochargers. They encase and support the turbocharger’s rotating components, allowing them to spin at high speeds. This housing facilitates the turbocharger’s function of compressing intake air, which is then fed into the engine’s combustion chambers. By increasing the density of the air, the turbocharger enhances engine performance and efficiency, allowing for greater power output without a corresponding increase in fuel consumption 1.

Purpose of the Turbocharger Bearing Housing

The Turbocharger Bearing Housing is designed to support the turbocharger’s rotating components in truck engines. It plays a role in maintaining the precise alignment and balance of these components, which is crucial for the efficient operation of the turbocharger. By ensuring smooth rotation, this housing contributes to increased airflow and power output, directly impacting the engine’s performance 2.

Key Features

The Turbocharger Bearing Housing is characterized by its durable construction materials and precision engineering. It is specifically designed for compatibility with Cummins engines, ensuring optimal performance and reliability. This housing incorporates unique design elements and technological advancements, such as advanced lubrication systems and robust bearing supports, to enhance its functionality and longevity 3.

Benefits

The advantages of the Turbocharger Bearing Housing include improved engine performance, increased fuel efficiency, enhanced durability, and reduced maintenance requirements. These benefits translate into cost savings and operational efficiencies for fleet operators and truck drivers, making it a valuable component for heavy-duty truck engines.

Troubleshooting and Maintenance

Common issues associated with turbocharger bearing housings include oil leaks, bearing wear, and turbocharger imbalance. Regular maintenance practices, such as inspection, lubrication, and replacement of worn-out parts, are recommended to prolong the lifespan of the component and ensure optimal performance. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the turbocharger system.

Compatibility with Cummins Engines

The Turbocharger Bearing Housing, identified by part number 3522740, is a critical component in the turbocharger system of various Cummins engines. This part is designed to house the bearings that support the turbocharger rotor, ensuring smooth and efficient operation.

N14 CELECT and N14 MECHANICAL Engines

The N14 CELECT and N14 MECHANICAL engines both utilize the turbocharger bearing housing part 3522740. These engines are known for their robust design and are commonly used in heavy-duty applications. The turbocharger bearing housing in these engines is engineered to withstand high rotational speeds and thermal stresses, ensuring longevity and reliability.

NH/NT 855 Engines

The NH/NT 855 engines also incorporate the turbocharger bearing housing part 3522740. These engines are part of Cummins’ lineup of medium-duty engines, offering a balance of power and efficiency. The bearing housing in these engines is designed to integrate seamlessly with the turbocharger system, providing the necessary support for the turbocharger’s operation.

QSK38 CM850 MCRS Engines

The QSK38 CM850 MCRS engines, which are part of Cummins’ heavy-duty engine range, also use the turbocharger bearing housing part 3522740. These engines are designed for demanding applications, such as marine and power generation. The bearing housing in these engines is built to handle the extreme conditions these applications present, ensuring consistent performance and durability.

Role of the Turbocharger Bearing Housing in Engine Systems

The Turbocharger Bearing Housing is an integral component in the efficient operation of various engine systems, particularly those utilizing aftermarket turbochargers and performance parts. Its primary function is to house and support the turbocharger’s bearings, ensuring smooth and reliable rotation of the turbine and compressor wheels.

Integration with Key Components

-

Aftermarket Turbocharger: When installing an aftermarket turbocharger, the Turbocharger Bearing Housing plays a significant role. It provides a stable environment for the turbocharger’s internals, allowing for enhanced performance and durability. The housing must be precisely aligned with the turbocharger to ensure optimal airflow and reduced friction.

-

Cam Follower Housing and Camshaft: In engines with complex valvetrains, such as those featuring a camshaft right bank, the Turbocharger Bearing Housing indirectly influences performance. By enhancing the turbocharger’s efficiency, it allows the engine to breathe better, which in turn requires the camshaft and cam follower housing to operate more effectively to manage increased air and fuel intake.

-

Connecting Rod and Piston: The efficiency of the turbocharger directly impacts the connecting rod and piston assembly. With the Turbocharger Bearing Housing ensuring smooth turbocharger operation, the engine can achieve higher boost levels. This increased boost enhances combustion efficiency, placing greater demands on the connecting rod and piston to handle the additional power and stress.

-

Core Assembly and Cylinder Head: The Turbocharger Bearing Housing is essential for the core assembly and cylinder head, as it contributes to improved airflow. Enhanced airflow leads to better combustion within the cylinder head, allowing the core assembly to operate more efficiently. This synergy is particularly noticeable in high-performance engines where every component must work in harmony.

-

EBM-Injector and Injector Plumbing: For engines equipped with EBM-injectors or other high-performance fuel injectors, the Turbocharger Bearing Housing ensures that the turbocharger can deliver consistent boost. This consistency is vital for the injectors to meter fuel accurately, maintaining the correct air-fuel ratio essential for peak performance and reliability.

-

EBM-Performance Parts and EBM-Turbocharger: When utilizing EBM-performance parts and EBM-turbochargers, the Turbocharger Bearing Housing is a linchpin. It ensures that the turbocharger’s bearings are well-supported, allowing the EBM-turbocharger to operate at its designed efficiency. This, in turn, maximizes the potential of EBM-performance parts by providing the necessary boost for enhanced engine output.

-

Heat3B Turbocharger and HC3 Turbocharger: For specialized turbochargers like the Heat3B and HC3, the Turbocharger Bearing Housing is vital. These turbochargers are often used in high-stress applications where reliability and performance are paramount. The housing’s role in maintaining bearing integrity ensures that these turbochargers can withstand the rigors of high-boost environments.

-

Turbocharger Kit: In a comprehensive turbocharger kit, the Turbocharger Bearing Housing is a foundational component. It ensures that all elements of the kit—from the turbocharger itself to the associated plumbing and performance parts—function cohesively. This integration is essential for achieving the desired performance gains and maintaining engine reliability.

Conclusion

The Turbocharger Bearing Housing, specifically Part #3522740 by Cummins, is a critical component in the turbocharger system of various Cummins engines. Its design ensures compatibility and performance across different engine types, making it a crucial part in enhancing engine efficiency and reliability. Regular maintenance and prompt troubleshooting of common issues are essential to prolong the lifespan of this part and ensure optimal performance of the turbocharger system.

SPECIFICATIONS

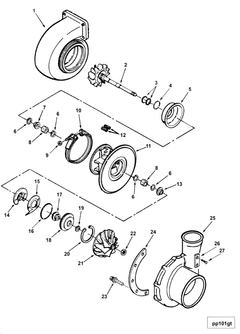

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Roll Pin | 2 | 3756135 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.