3899343

Turbocharger Gasket

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding the Cummins 3899343 Turbocharger Gasket: A Comprehensive Guide

Introduction to Turbocharger Gaskets

Turbocharger gaskets are critical components in the operation of turbocharged engines, ensuring efficient and effective turbocharger function. These gaskets are designed to create a seal between the turbocharger and the engine, preventing leaks and maintaining necessary pressure for optimal performance 1.

The Role of a Turbocharger Gasket

A turbocharger gasket serves several essential functions:

- Sealing: Ensures no leaks between the turbocharger and the engine, maintaining the integrity of the exhaust and intake systems.

- Pressure Maintenance: Helps maintain the pressure differentials required for the turbocharger to operate correctly.

- Protection: Protects internal engine components from debris and contaminants that could otherwise enter through the turbocharger housing.

The Cummins 3899343 Turbocharger Gasket

The Cummins 3899343 turbocharger gasket is specifically designed for use in Cummins engines, renowned for their durability and reliability in heavy-duty applications. This gasket is engineered to meet the stringent demands of commercial truck engines, ensuring longevity and performance 2.

Purpose and Importance in Truck Operations

In commercial trucks, the turbocharger gasket plays a pivotal role in the overall efficiency and performance of the engine. Proper sealing and pressure maintenance are crucial for maximizing fuel efficiency, power output, and reducing emissions. For fleet operators and mechanics, understanding the importance of this component can lead to better maintenance practices and reduced downtime.

Troubleshooting and Maintenance

Proper maintenance of the turbocharger gasket is essential to prevent issues such as leaks, reduced performance, and potential engine damage. Here are some troubleshooting and maintenance tips:

- Regular Inspections: Regularly inspect the gasket for signs of wear, damage, or leaks. Look for any discoloration, cracks, or deformation.

- Clean Installation: Ensure that the gasket is installed correctly and that the mating surfaces are clean and free of debris. Any contaminants can compromise the seal.

- Proper Torque Specifications: Follow the manufacturer’s torque specifications when installing the turbocharger. Over-tightening can damage the gasket, while under-tightening can lead to leaks.

- Replacement: If the gasket shows signs of wear or leaks, it should be replaced promptly. Using an OEM or equivalent quality gasket is recommended to ensure compatibility and performance.

Cummins: A Leader in Engine Technology

Cummins is a renowned name in the engine manufacturing industry, known for producing high-quality, reliable engines for commercial trucks and heavy-duty applications. Their commitment to innovation and quality ensures that their parts, including the 3899343 turbocharger gasket, meet the highest standards 3.

Expert Insights

As an expert in commercial truck parts, it is clear that the turbocharger gasket is a vital component in the operation of turbocharged engines. Proper maintenance and understanding of its function can significantly impact the performance and longevity of the engine. Mechanics and fleet operators should prioritize regular inspections and follow best practices for installation and replacement to ensure optimal engine performance.

By adhering to these guidelines and leveraging the expertise of manufacturers like Cummins, professionals in the industry can maintain the efficiency and reliability of commercial truck engines.

Turbocharger Gasket Fitment for Cummins Engines

The turbocharger gasket part number 3899343, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This gasket is a critical component that ensures a proper seal between the turbocharger and the engine, preventing leaks and maintaining optimal performance. Below is a detailed overview of the engines that this gasket is compatible with:

G-Series Engines

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

ISM Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

L10 Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

M11 Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

N14 Engines

- N14 G

QSK60 Engines

- QSK60 CM850 MCRS

QSM11 Engines

- QSM11 CM570

- QSM11 CM876

QSNT14 Engines

- QSNT14 CM876 N102

This turbocharger gasket is engineered to provide a reliable seal, ensuring that the turbocharger operates efficiently and effectively across these diverse engine models. Each gasket is designed to meet the specific requirements of the engine it is intended for, ensuring compatibility and performance.

Role of Part 3899343 Turbocharger Gasket in Engine Systems

The 3899343 Turbocharger Gasket is an essential component in the integration and operation of various engine systems. Its primary function is to ensure a secure and leak-free seal between the turbocharger and the cylinder block, as well as other critical components.

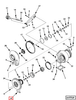

Integration with Key Components

- Cylinder Block: The turbocharger gasket facilitates a tight seal between the turbocharger and the cylinder block. This seal is vital for maintaining the integrity of the pressurized air flow from the turbocharger to the engine’s combustion chambers.

- Turbocharger: Directly interfacing with the turbocharger, the gasket prevents any exhaust gas leakage that could compromise engine performance and efficiency.

- Upper Engine Gasket Kit/Set: When used in conjunction with an upper engine gasket kit or set, the turbocharger gasket contributes to the overall sealing strategy of the engine, ensuring that all pressurized systems operate within designed parameters.

- Turbocharger Gasket Kit: Often included in a turbocharger gasket kit, this part works alongside other gaskets to provide comprehensive sealing solutions for the turbocharger system.

- Turbocharger Kit: In a turbocharger kit, the gasket is a fundamental component that ensures the turbocharger is properly sealed to the engine, allowing for optimal performance and durability.

- Turbocharger Repair Kit: During repairs, the turbocharger gasket is frequently replaced to restore the seal integrity, which is essential for the turbocharger to function correctly post-repair.

- Turbocharger Oil Plumbing and Turbocharger Plumbing: The gasket interacts with the oil and plumbing systems of the turbocharger, ensuring that oil flow and exhaust gas routing are maintained without leaks.

- Heat Exchanger and Wastegate Turbocharger: In systems utilizing a heat exchanger and wastegate turbocharger, the gasket helps maintain the pressure differentials necessary for efficient operation.

- Overhaul (M-11) Kit and Overhaul Kit: During an engine overhaul, the turbocharger gasket is a key replacement part to ensure that the turbocharger is re-installed with a fresh, reliable seal.

- Filter Head Kit and Oil Cooler Kit: Although not directly interfacing with these kits, the turbocharger gasket’s role in maintaining system pressure indirectly supports the efficient operation of filter heads and oil coolers by ensuring consistent turbocharger performance.

- PDC (Power Distribution Center): While the PDC is an electrical component, the efficient operation of the turbocharger (sealed by the gasket) ensures that the engine runs smoothly, which in turn supports stable electrical system performance.

- Campaign Kit: In scenarios where campaign kits are employed for engine enhancements or repairs, the turbocharger gasket may be included to ensure that any modifications to the turbocharger system are sealed properly.

The turbocharger gasket’s role in these systems underscores its importance in maintaining engine efficiency, performance, and reliability.

Conclusion

Understanding the critical role of the Cummins 3899343 turbocharger gasket in engine systems is essential for maintaining the efficiency and reliability of commercial truck engines. Proper maintenance, regular inspections, and adherence to manufacturer guidelines are crucial for ensuring optimal performance and longevity of the engine. By leveraging the expertise of manufacturers like Cummins and following best practices, professionals in the industry can achieve superior engine performance and reduced downtime.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.