3928629

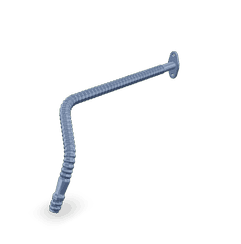

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Oil Drain Connection (Part #3928629) manufactured by Cummins is a component designed to facilitate the drainage of oil from the turbocharger. This part is integral to the maintenance and operation of commercial trucks, ensuring that the turbocharger operates efficiently and remains in optimal condition.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are designed to allow the removal of oil that has been used to lubricate the turbocharger’s moving parts. This process is vital for maintaining the health of the turbocharger, as it prevents the buildup of contaminants and ensures that the lubricant remains effective. The connection typically interfaces with the turbocharger housing, providing a pathway for oil to be drained periodically 1.

Role and Function in Truck Operation

The Turbocharger Oil Drain Connection plays a significant role in the operation of a truck by enabling the regular drainage of oil from the turbocharger. This function is important for several reasons:

- It helps in removing oil that may have become contaminated with soot or other particles, which can impair lubrication.

- It allows for the inspection of the oil’s condition, providing insights into the turbocharger’s wear and performance.

- It contributes to the overall efficiency and reliability of the engine by ensuring that the turbocharger operates under optimal lubrication conditions 2.

Key Features

The Cummins Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability:

- Design Elements: The connection is engineered to fit securely within the turbocharger housing, ensuring a leak-free seal.

- Materials Used: Constructed from high-quality materials, the connection is resistant to corrosion and capable of withstanding the high temperatures and pressures within the turbocharger environment.

- Unique Characteristics: The design may include features such as a built-in filter to capture debris during oil drainage, enhancing the cleanliness of the system 3.

Benefits

Using the Cummins Turbocharger Oil Drain Connection offers several benefits:

- Improved Turbocharger Efficiency: Regular oil drainage helps maintain the turbocharger’s efficiency by ensuring clean lubrication.

- Enhanced Engine Performance: A well-maintained turbocharger contributes to better engine performance and fuel efficiency.

- Increased Reliability: Proper maintenance of the turbocharger, facilitated by the oil drain connection, leads to increased reliability and longevity of the engine.

Installation Process

Installing the Turbocharger Oil Drain Connection involves the following steps:

- Preparation: Ensure the turbocharger is cool and the engine is off. Gather necessary tools, including a socket wrench and a drain pan.

- Location: Identify the oil drain connection point on the turbocharger housing.

- Drainage: Loosen the connection using the socket wrench and allow the oil to drain into the pan.

- Reassembly: Once the oil has been completely drained, retighten the connection to ensure a secure seal.

Maintenance Tips

To ensure the optimal performance and longevity of the Turbocharger Oil Drain Connection, consider the following maintenance tips:

- Regular Inspection: Check the connection for signs of wear or damage during routine maintenance checks.

- Cleaning: Ensure that the area around the connection is clean and free from debris to prevent contamination.

- Lubrication: Apply a compatible lubricant to the threads of the connection to facilitate easy removal during future drainage procedures.

Troubleshooting Common Issues

Common issues with the Turbocharger Oil Drain Connection may include leaks, blockages, or malfunctions. To address these problems:

- Leaks: Inspect the connection for tightness and ensure there are no cracks or damage. Retighten or replace if necessary.

- Blockages: If oil drainage is slow or obstructed, check for debris within the connection or housing and clean as needed.

- Malfunctions: If the connection fails to operate correctly, it may require replacement or professional repair.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality components and commitment to innovation. With a rich history of producing reliable and efficient engine parts, Cummins continues to be a trusted name in the commercial trucking sector.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection part 3928629, manufactured by Cummins, is a critical component in the lubrication system of various Cummins engines. This part ensures that oil is properly drained from the turbocharger, maintaining optimal engine performance and longevity.

Compatible Engines

6C8.3, C GAS PLUS CM556, C8.3 G, G8.3, GTA8.3 CM558

These engines, which include the 6C8.3 and various configurations of the C8.3 and G8.3 series, benefit from the Turbocharger Oil Drain Connection. This part is essential for maintaining the oil flow and pressure within the turbocharger, preventing oil starvation and ensuring efficient operation.

L8.9, L8.9 CM2670 L134C, L8.9 L121, L8.9G CMOH2.0 L125B, L9.3 L105, L9.5 L117

The L8.9 series engines, including the L8.9, L8.9 CM2670 L134C, L8.9 L121, L8.9G CMOH2.0 L125B, L9.3 L105, and L9.5 L117, all utilize the Turbocharger Oil Drain Connection. This part is crucial for these engines as it ensures the turbocharger is adequately lubricated, which is vital for maintaining the high performance and reliability expected from these models.

QSC8.3 CM2880 C102, QSL9 CM850 (CM2850), QSL9.3 CM2880 L113

The QSC8.3 CM2880 C102, QSL9 CM850 (CM2850), and QSL9.3 CM2880 L113 engines also incorporate the Turbocharger Oil Drain Connection. This part is integral to these engines’ lubrication systems, ensuring that oil is efficiently drained from the turbocharger, which helps in maintaining the engine’s performance and extending its operational life.

By ensuring proper oil drainage, the Turbocharger Oil Drain Connection part 3928629 plays a vital role in the maintenance and performance of these Cummins engines.

Role of Part 3928629 Turbocharger Oil Drain Connection in Engine Systems

In the context of engine systems, the Turbocharger Oil Drain Connection, identified by part number 3928629, serves a significant function within the turbocharger and its associated plumbing. This component is integral to the maintenance and operational efficiency of the turbocharger system.

Turbocharger Integration

The Turbocharger Oil Drain Connection is designed to interface directly with the turbocharger. Its primary role is to facilitate the drainage of oil from the turbocharger’s lubrication system. This is essential for maintaining the turbocharger’s bearings and other moving parts, ensuring they operate smoothly and efficiently. By allowing for the regular removal of used oil, this connection helps in preventing the buildup of contaminants and degradation products that could otherwise impair turbocharger performance.

Turbocharger Plumbing

In the turbocharger plumbing system, the Turbocharger Oil Drain Connection acts as a vital junction. It is part of a network that includes oil supply lines, return lines, and various sensors and valves. This connection ensures that the oil circuit within the turbocharger system is complete and functional. It allows for the controlled drainage of oil, which is then typically returned to the engine’s lubrication system for filtration and recirculation. This process is key to maintaining the overall health of the engine’s lubrication system, as it ensures that only clean, properly conditioned oil is circulated through the engine and turbocharger.

Plumbing System

Within the broader plumbing system of the engine, the Turbocharger Oil Drain Connection plays a role in the management of oil flow and pressure. It is connected to the engine’s oil supply and return lines, facilitating a seamless integration between the turbocharger’s oil system and the engine’s lubrication circuit. This connection ensures that the turbocharger receives a consistent supply of oil under the correct pressure, which is vital for its efficient operation. Additionally, it aids in the regulation of oil temperature within the turbocharger, contributing to the overall thermal management of the engine system.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3928629) is a key component in the turbocharger and engine plumbing systems. It ensures the efficient drainage and circulation of oil, contributing to the maintenance of turbocharger health, the integrity of the turbocharger plumbing, and the overall performance of the engine system.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.