This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5292626 Valve Spring is a component designed for use in heavy-duty truck engines. Its purpose is to ensure the proper operation of the engine’s valve system, which is vital for the engine’s overall performance and efficiency. This valve spring is engineered to meet the demanding requirements of heavy-duty applications, providing reliable valve actuation under various operating conditions.

Basic Concepts of Valve Springs

Valve springs are mechanical components used in internal combustion engines to control the opening and closing of the intake and exhaust valves. They operate by applying force to keep the valves seated on their seats when the engine is not in the valve opening phase. This ensures that the valves open and close at the correct times in the engine’s operating cycle, which is crucial for efficient combustion and engine performance. Valve springs must withstand high temperatures, pressures, and cyclic loads, making their design and material selection critical for engine reliability 3.

Purpose of the Cummins 5292626 Valve Spring

This Cummins part plays a specific role in the operation of a truck engine by maintaining valve timing and ensuring efficient engine performance. It is designed to provide the necessary force to keep the valves closed during the engine’s compression and combustion phases and to open them at the appropriate times during the intake and exhaust phases. This precise control over valve operation is essential for optimal engine efficiency, power output, and emissions control 2.

Key Features

The Cummins 5292626 Valve Spring is characterized by its robust design and the use of high-quality materials, which contribute to its performance and durability. It features a multi-coil construction that allows for greater flexibility and resilience under the high stresses encountered in heavy-duty engine applications. The spring is made from materials that offer excellent resistance to fatigue and thermal degradation, ensuring long-term reliability. Additionally, its design may include features such as a damper to reduce spring oscillations and noise, enhancing both performance and longevity 4.

Benefits

Using the Cummins 5292626 Valve Spring offers several benefits, including improved engine efficiency, reliability, and longevity. Its precise control over valve operation contributes to more efficient combustion, which can lead to better fuel economy and reduced emissions. The durability of the spring ensures that it can withstand the rigors of heavy-duty use, providing consistent performance over the engine’s lifespan. Furthermore, the design of the spring may contribute to reduced engine noise and vibration, enhancing the overall driving experience 1.

Installation and Maintenance

Proper installation of the Cummins 5292626 Valve Spring is crucial for ensuring its effective operation and the engine’s performance. Installation procedures should follow manufacturer guidelines to ensure the spring is correctly seated and tensioned. Regular maintenance, including inspection for signs of wear or damage, is recommended to ensure the valve spring remains in optimal condition. Maintenance practices may also include checking for proper valve clearance and ensuring that all related components, such as valve keepers and locks, are in good condition 2.

Troubleshooting Common Issues

Common issues with valve springs, such as spring failure or valve train noise, can arise due to wear, fatigue, or improper installation. Troubleshooting these issues involves a systematic approach to diagnosing the root cause. This may include visual inspection for physical damage, checking for proper valve clearance, and ensuring that all components of the valve train are correctly installed and functioning as intended. Addressing these issues promptly can prevent more severe engine damage and ensure continued reliable operation 2.

Performance Enhancements

The Cummins 5292626 Valve Spring contributes to overall engine performance by providing precise valve control and durability under high-stress conditions. Compared to standard valve springs, it may offer enhancements in engine efficiency, power output, and reliability. Its design and material selection are tailored to meet the specific demands of heavy-duty truck engines, ensuring that it can deliver consistent performance even under the most challenging operating conditions 4.

Compatibility of Valve Spring Part 5292626 with Cummins Engines

The Cummins Valve Spring part number 5292626 is designed to fit a variety of Cummins engine models. This part is crucial for maintaining the proper operation of the engine’s valve train system, ensuring efficient and reliable performance. Below is a detailed overview of the engines that are compatible with this specific valve spring.

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

QSC and QSL Series Engines

- QSC8.3 CM2880 C102

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

L Series Engines

- L8.9

- L8.9 L121

By ensuring that the valve spring part 5292626 is used in the appropriate engine models, operators can maintain the performance and reliability of their Cummins engines. This compatibility is crucial for the longevity and efficiency of the engine, making it a vital component for maintenance and repair.

Role of Part 5292626 Valve Spring in Engine Systems

The 5292626 Valve Spring is an essential component in the operation of various engine systems, ensuring the proper functioning of several key elements.

Interaction with the Camshaft

The valve spring works in tandem with the camshaft to control the opening and closing of the engine’s valves. As the camshaft lobes rise and fall, they push against the valve stems. The valve spring counteracts this motion, ensuring that the valves return to their closed position promptly and consistently. This interaction is vital for maintaining the engine’s timing and efficiency 3.

Coordination with Connecting Rod and Piston

While the connecting rod and piston are primarily responsible for converting the linear motion of the piston into rotational motion of the crankshaft, the valve spring plays a supporting role. Proper valve timing, ensured by the valve spring, allows for optimal air-fuel mixture intake and exhaust gas expulsion. This, in turn, enhances the efficiency of the piston’s motion, leading to improved overall engine performance 3.

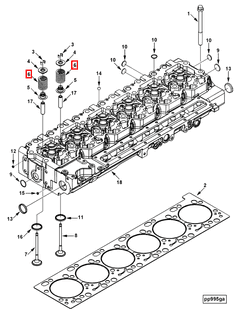

Integration with Cylinder Head

The cylinder head houses the valves that the valve spring controls. The spring’s role is to keep the valves seated when they are not being actuated by the camshaft. This seating is essential for maintaining compression within the combustion chamber, which is critical for efficient combustion and power generation 3.

Relationship with Fuel Manifold and Injector

The fuel manifold and injector work together to deliver the precise amount of fuel into the combustion chamber. The valve spring ensures that the intake valves open and close at the correct times, allowing for the proper intake of the air-fuel mixture. This timing is essential for the injector to deliver fuel effectively, optimizing combustion and engine performance 3.

Enhancement of Performance Parts

In engines equipped with performance parts, the valve spring’s role becomes even more significant. High-performance camshafts, for example, may require stronger valve springs to handle increased valvetrain stresses. The valve spring ensures that these performance components operate within their designed parameters, contributing to enhanced engine responsiveness and power output 4.

Conclusion

The Cummins 5292626 Valve Spring is a critical component in heavy-duty truck engines, ensuring efficient and reliable valve operation. Its robust design, high-quality materials, and precise control over valve timing contribute to improved engine performance, efficiency, and longevity. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part. By understanding its role and compatibility with various Cummins engine models, operators can ensure the optimal performance and reliability of their engines.

-

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ ↩ ↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ ↩ ↩ ↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.