This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

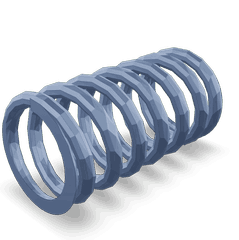

The Valve Spring 5316172 by Cummins is a critical component designed to ensure the proper operation of the engine’s valve train system. This spring is essential for maintaining correct valve timing and performance, which are vital for the engine’s overall efficiency and reliability.

Basic Concepts of Valve Springs

Valve springs are mechanical components within an engine that control the opening and closing of the valves. They apply force to keep the valves seated on the valve seat when the engine is not in operation and to return the valves to their seated position after being opened by the camshaft. The proper functioning of valve springs is crucial for maintaining valve timing and ensuring smooth and efficient engine operation 1.

Role of the Valve Spring 5316172 in Truck Operation

In commercial truck engines, the Valve Spring 5316172 ensures that the valves open and close at the correct times, contributing to engine efficiency and reliability. This precise timing allows for optimal air and fuel mixture intake and exhaust gas expulsion. The spring’s design and material properties enable it to withstand the high temperatures and pressures within the engine, enhancing its durability and longevity 2.

Key Features

The Valve Spring 5316172 is characterized by its specific design and the materials used in its construction. It is made from high-quality spring steel, providing the necessary strength and flexibility to endure the demanding conditions within a commercial truck engine. The spring’s design includes multiple coils, allowing it to compress and expand efficiently, ensuring consistent valve operation. Additionally, the spring is coated to resist corrosion and wear, enhancing its durability in harsh operating environments.

Benefits

The Valve Spring 5316172 offers several benefits, including improved engine performance through precise valve timing and reliable valve operation. Its durable construction contributes to increased engine reliability, reducing the likelihood of valve-related issues. Furthermore, the enhanced durability of the spring can lead to potential cost savings by reducing the frequency of maintenance and replacement, thereby lowering overall engine maintenance costs 3.

Troubleshooting and Maintenance

Common issues with valve springs may include spring failure due to fatigue, corrosion, or improper installation. Troubleshooting these problems involves inspecting the spring for signs of wear, corrosion, or damage and ensuring that it is correctly installed and seated. Regular maintenance practices, such as checking the spring’s condition during routine engine inspections and replacing it as necessary, can help ensure the longevity and optimal performance of the Valve Spring 5316172.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Valve Spring 5316172, which is designed to meet the rigorous demands of commercial truck engines.

Valve Spring 5316172 Compatibility with Cummins Engines

The Cummins Valve Spring part number 5316172 is designed to fit a variety of Cummins engines, ensuring optimal performance and longevity. Here is a detailed look at the compatibility of this valve spring with different engine models:

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

The ISC series engines benefit from the 5316172 valve spring due to its robust design, which helps maintain the high-pressure and high-temperature environment typical of these engines.

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

The ISL series engines, known for their reliability and efficiency, are well-suited for the 5316172 valve spring. This part ensures the valves operate smoothly, contributing to the engine’s overall performance.

L Series Engines

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L9 CM2670 L128B

The L series engines, which are often used in heavy-duty applications, are compatible with the 5316172 valve spring. This compatibility ensures the valves can withstand the demanding conditions of these engines.

QSC and QSL Series Engines

- QSC8.3 CM2880 C102

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

The QSC and QSL series engines, which are designed for both on-highway and off-highway applications, also fit the 5316172 valve spring. This compatibility is crucial for maintaining the engines’ performance and durability in various operational environments.

The 5316172 valve spring is engineered to provide reliable performance across these diverse engine models, ensuring that the valves operate efficiently and effectively.

Understanding the Role of Part 5316172 Valve Spring in Engine Systems

The part 5316172 Valve Spring is an essential component in the orchestration of various engine systems, ensuring the seamless operation of the engine’s internal mechanisms. Its primary function is to maintain the proper sealing of the valve against the valve seat during engine operation, which is fundamental for the engine’s performance and efficiency.

Interaction with the Camshaft

The Valve Spring works in tandem with the camshaft. As the camshaft rotates, it actuates the valve lifters, which in turn open the valves. The Valve Spring ensures that the valve returns to its closed position once the camshaft lobe has passed, maintaining the valve’s proper timing and sealing.

Coordination with Connecting Rod and Piston

The operation of the Valve Spring is intrinsically linked to the movement of the connecting rod and piston. As the piston moves downward during the intake stroke, the Valve Spring allows the intake valve to open, drawing the air-fuel mixture into the cylinder. Conversely, during the exhaust stroke, the Valve Spring facilitates the opening of the exhaust valve, allowing the spent gases to be expelled from the cylinder.

Integration with the Cylinder Head

The Valve Spring is mounted within the cylinder head, where it exerts force on the valve keeper to keep the valve stem and valve in proper alignment. This alignment is vital for the valve to make a proper seal against the valve seat, preventing any leakage of the air-fuel mixture or exhaust gases.

Relationship with the Fuel Manifold and Injector

The efficiency of the fuel manifold and injector is influenced by the precise operation of the Valve Spring. The Valve Spring ensures that the intake valve opens and closes at the correct times, allowing the injector to deliver the fuel into the cylinder at the optimal moment. This timing is essential for the proper combustion of the air-fuel mixture, directly impacting the engine’s performance and fuel efficiency.

Enhancement of Performance Parts

In engines equipped with performance parts, the Valve Spring plays a pivotal role. High-performance camshafts, for instance, require Valve Springs that can handle increased valvetrain stresses and higher RPMs. The Valve Spring must be capable of maintaining valve control under these demanding conditions, ensuring that the performance parts function as intended without compromising engine integrity.

Conclusion

The Valve Spring 5316172 is a fundamental component that interacts with various engine systems to ensure the engine operates efficiently and effectively. Its role in maintaining valve timing and sealing is indispensable for the overall performance of the engine.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.