This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

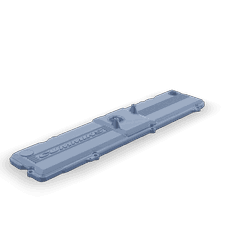

The Valve Cover Assembly 3970866, designed by Cummins for heavy-duty truck engines, serves multiple functions within the engine system, primarily focused on protecting internal components and managing emissions. Its role is significant in maintaining the efficiency and reliability of the engine, contributing to the overall performance of heavy-duty trucks.

Purpose and Function

This Cummins part provides a protective enclosure for the valve train components, including the camshaft, rocker arms, and other associated parts. By sealing these components, the valve cover helps to prevent contaminants from entering the engine, which could lead to wear and reduced efficiency. Additionally, the assembly is involved in managing emissions by containing and directing crankcase ventilation, which helps in reducing the release of harmful gases into the atmosphere 1.

Key Features

Constructed from durable materials, the Valve Cover Assembly 3970866 is designed to withstand the high temperatures and pressures present in a heavy-duty engine environment. Its design incorporates precise gasket seating to ensure a tight seal, and robust mounting points to secure it firmly in place. Unique attributes of this assembly may include advanced sealing technologies and materials that offer superior resistance to oil and heat 2.

Benefits

Utilizing the Valve Cover Assembly 3970866 offers several advantages. It provides enhanced protection for the engine’s internal components, contributing to longer engine life and more reliable operation. The assembly’s design also supports improved engine performance by ensuring efficient crankcase ventilation and reducing the potential for oil leaks. Furthermore, by contributing to the engine’s overall efficiency and longevity, this component can lead to potential cost savings through reduced maintenance needs 3.

Installation and Compatibility

Proper installation of the Valve Cover Assembly 3970866 is crucial for ensuring its effectiveness and the engine’s performance. Installation guidelines should be followed closely, including any specific requirements for torque settings and gasket placement to ensure a secure and leak-free fit. Compatibility with various engine models should be verified to ensure optimal performance and integration within the engine system 4.

Maintenance and Troubleshooting

Routine maintenance practices for the Valve Cover Assembly 3970866 include regular inspections for signs of wear or damage, ensuring gaskets are in good condition, and checking for any leaks. Troubleshooting common issues may involve addressing gasket failures, ensuring proper torque on mounting bolts, and verifying the integrity of the sealing surfaces. Adhering to these practices can help maintain the longevity and optimal performance of the assembly.

Safety Considerations

When working with the Valve Cover Assembly 3970866, it is important to observe safety protocols to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for installation and maintenance. Awareness of the high temperatures and pressures within the engine compartment is crucial to avoid injury.

Environmental Impact

The production, use, and disposal of the Valve Cover Assembly 3970866 have environmental implications. Cummins is committed to minimizing the environmental footprint of its products through sustainable manufacturing practices, the use of recyclable materials where possible, and efforts to reduce emissions during production. The design of the valve cover also contributes to lower emissions from the engine it protects, aligning with broader environmental goals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for a variety of applications, from on-highway to off-highway and stationary power.

Compatibility with Cummins Engines

The Valve Cover Assembly part number 3970866, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This part is crucial for maintaining the integrity of the engine’s valve train system by providing a sealed environment for the valves and related components.

ISC Series Engines

- ISC CM2150

- ISC CM850

- ISL CM2150

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

L Series Engines

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L9 CM2670 L128B

- L9.5 L117

QSC and QSL Series Engines

- QSC8.3 CM2880 C102

- QSC8.3 CM850(CM2850)

- QSL8.9 CM2150 L141

- QSL9 CM850(CM2850)

- QSL9.3 CM2880 L113

By ensuring the correct fitment of the 3970866 Valve Cover Assembly, engine owners can maintain optimal performance and longevity of their Cummins engines.

Role in Engine Systems

The Valve Cover Assembly, identified by part number 3970866, is a critical component in the engine system, providing several key functions that contribute to the overall performance and integrity of the engine.

Sealing and Protection: The primary role of the Valve Cover Assembly is to seal the top of the engine, specifically the cylinder head and valve train components. This seal is vital for preventing oil leaks and contaminants from entering the engine. By maintaining a secure seal, the Valve Cover Assembly helps to protect the internal components from dirt, debris, and moisture, which can lead to wear and reduced efficiency.

Oil Management: The Valve Cover Assembly is integral to the engine’s oil management system. It houses the PCV (Positive Crankcase Ventilation) valve, which regulates the flow of gases from the crankcase back into the intake manifold. This process helps to reduce emissions and maintain proper oil levels by preventing the buildup of pressure within the crankcase. Additionally, the Valve Cover Assembly often includes passages for oil circulation, ensuring that lubricant reaches the upper valve train components, such as camshafts and rocker arms.

Structural Support: Beyond its sealing and oil management functions, the Valve Cover Assembly provides structural support to the engine. It secures various components in place, including the camshaft(s), valve springs, and rocker arms. This support is essential for maintaining the precise alignment and operation of these parts, which are critical for the engine’s valve timing and overall performance.

Access and Maintenance: The Valve Cover Assembly is designed to be easily removable, allowing mechanics and engineers access to the valve train for inspection, maintenance, and repair. This feature is particularly important during routine services, such as valve adjustments or camshaft replacements, as it enables quick and efficient access to these components without requiring extensive disassembly of the engine.

Conclusion

In summary, the Valve Cover Assembly (part 3970866) plays a multifaceted role in engine systems, encompassing sealing, oil management, structural support, and facilitating maintenance access. Its proper installation and maintenance are essential for ensuring the engine operates efficiently and reliably.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning, 2014.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.